5 parts list, 6 clean-up, 7 disassembly – Trebor 610RC Magnum User Manual

Page 13

M610RC

Page 13

8100 South 1300 West, West Jordan, Utah 84088 USA Tel: 801-563-0303 Fax: 801-255-2312

www.treborintl.com

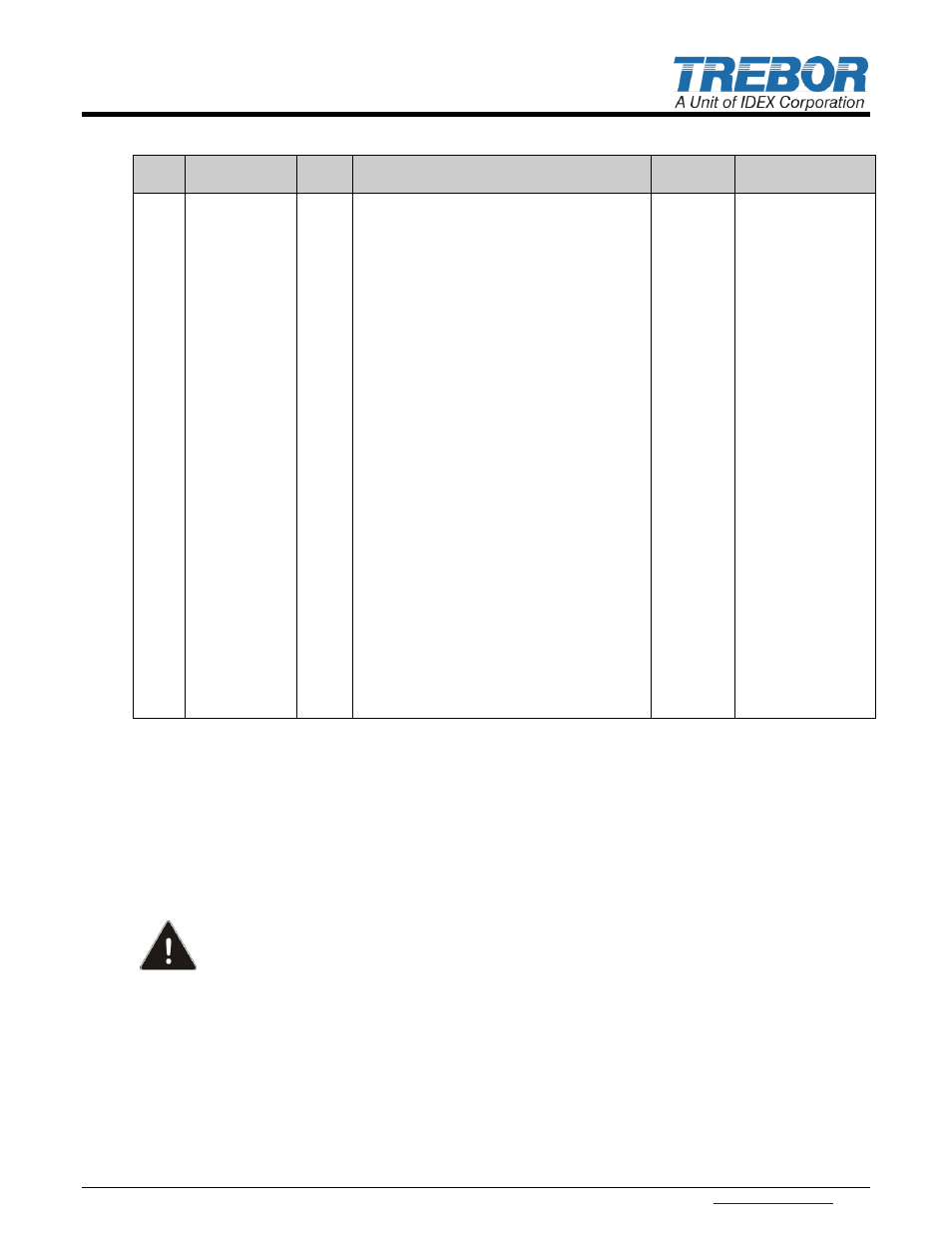

6.5

PARTS LIST

ILL

NO

PART NO

QTY

DESCRIPTION

PM

YEAR #

MATERIAL

1

1100C0026

1

Shuttle Plug

PP

2

11001230

1

Detent

1 & 2

Acetal, SS

3

11001210

1

Shuttle Assembly

1 & 2

SS410, Buna

4

C0135

1

Check Muffler Assembly

2

PP, NPRN

5

98001109

12

Tie Bolt Cap

2

PU

6

98002338

6

Nut, Flanged

SS18-8

7

C0142

1

Master Head

PP

8

11001220

2

Pilot Valve

Brass, SS, NBR

9

98003600

2

Main Seal

2

Viton

10

C0100

2

Diaphragm Set

2

PFA

11

C0095

2

Push Plate

PTFE

12

1610B0022

1

Shaft

2

PFA

13

98001976

2

Shaft Seal

2

PTFE

14

C0141

1

Body

PTFE

15

98002334

4

O-Ring, PTFE Check Valve

2

PTFE

16

98001415

4

Check Ball

2

PTFE

17

1610B0007

2

Suction Sleeve

PTFE

18

1610B0008

2

Discharge Sleeve

PTFE

19

AM084

2

Seal, Check Bore Cap

2

PTFE

20

C0144

2

Check Bore Cap

PTFE

21

C0143

1

Slave Head

PP

22

1610B0010

6

Tie Bolt Assembly

SS416, PFA

23

AM022

1

Mounting Base

PP

24

98003207

4

Mounting Screw

PP

25

98003071

1

Locking Lever Screw

PP

26

AM023

1

Locking Lever

PP

27

C0102

1

Quick Release Base

PP

28

1610A0013

1

Pilot Transfer Tube

PFA

29

98002331

2

O-Ring, Transfer Tube

2

Viton

30

1110A0022

2

Main Transfer Tube

PFA

31

98002332

2

O-Ring, Transfer Tube

2

Viton

32

98003599

2

Conductive Pin

SS

33

C0145

1

Conductive Connector Group

SS

6.6

CLEAN-UP

The pump fluid cavities may be flushed clean by cycling with the suction (IN) and discharge (OUT) lines

connected to a DI water flushing or rinsing tank. Flushing using an external pressure source without

allowing the pump to cycle will result in incomplete removal of potentially dangerous chemicals.

6.7

DISASSEMBLY

During the life of the pump it will be necessary to perform certain preventative maintenance procedures to

ensure its continued high performance operation. This section and the next (6.8 Assembly) are provided

for the user’s convenience in disassembly and re-assembly procedures.

CAUTION: Pump assembly and disassembly must be performed by authorized and qualified

personnel who have fully read this manual. If not, the pump could be damaged and people and

the environment placed at risk when operating this pump in explosive hazard areas.

Thoroughly clean / flush the pump using DI water (Refer to Section 6.6 Clean Up).

Unlock pump from quick release base by pulling out locking lever on front of base. Then slide pump

forward until it stops. Lift pump off base.

Remove check muffler assembly.

Remove tie bolt caps from both heads.

Remove flanged nuts from the tie bolt assemblies. (Master Head side.) Using both 3/8” nut drivers.

Leave tie bolts in place.

Lay the pump on the slave head side.