5 transport, storage and disposal, 1 transport securing for kse/f, 2 transport securing for kse -c – Richter KSE-C/F Series Safety Valves User Manual

Page 7: Clean air act (ta luft), Transport securing for kse/f, Transport securing for kse -c, 5transport, storage and disposal, Series kse/f, kse-c/f

Series KSE/F, KSE-C/F

Page 7

9530-050-en

Revision 04

TM 7489

Edition 03/2009

4

Safety note for valves, certified to Clean Air Act (TA Luft)

On request, this valve can be supplied compliant with

the German Clean Air Code.

Certificate / Manufacturer Declaration Validity is

dependent on the operating instructions being read

and observed.

In particular, servicing must be conducted at regular

intervals, and the bolted connections relevant for

tightness must be inspected and retightened if

necessary.

5

Transport, storage and disposal

It is imperative, for all transport work, to

observe generally accepted engineering

practice and the accident prevention

regulations.

The safety valve is supplied with flange caps.

Do not remove them until just before

installation. They protect the plastic surfaces

against dirt and mechanical damage.

Handle the goods being transported with care. During

transport the valve must be protected against impacts

and collisions.

Never transport the valve using the lifting lever

238.

See sectional drawing and details in Section 10.

Transport the valve upright in a box or on a pallet on a

soft surface and deposit gently on flat ground.

Directly after receipt of the goods, the consignment

must be checked for completeness and any in-transit

damage.

Do not damage epoxy-coating.

With the KSE/F and KSE-C/F 100/150 valves, a ring

bolt 908/1 is screwed into the lifting cap which

facilitates transport. It must be ensured that the ring

bolt lies on the axis of the discharge flange so that

equilibrium is guaranteed when the valve is lifted. See

View W in Section 10.4.

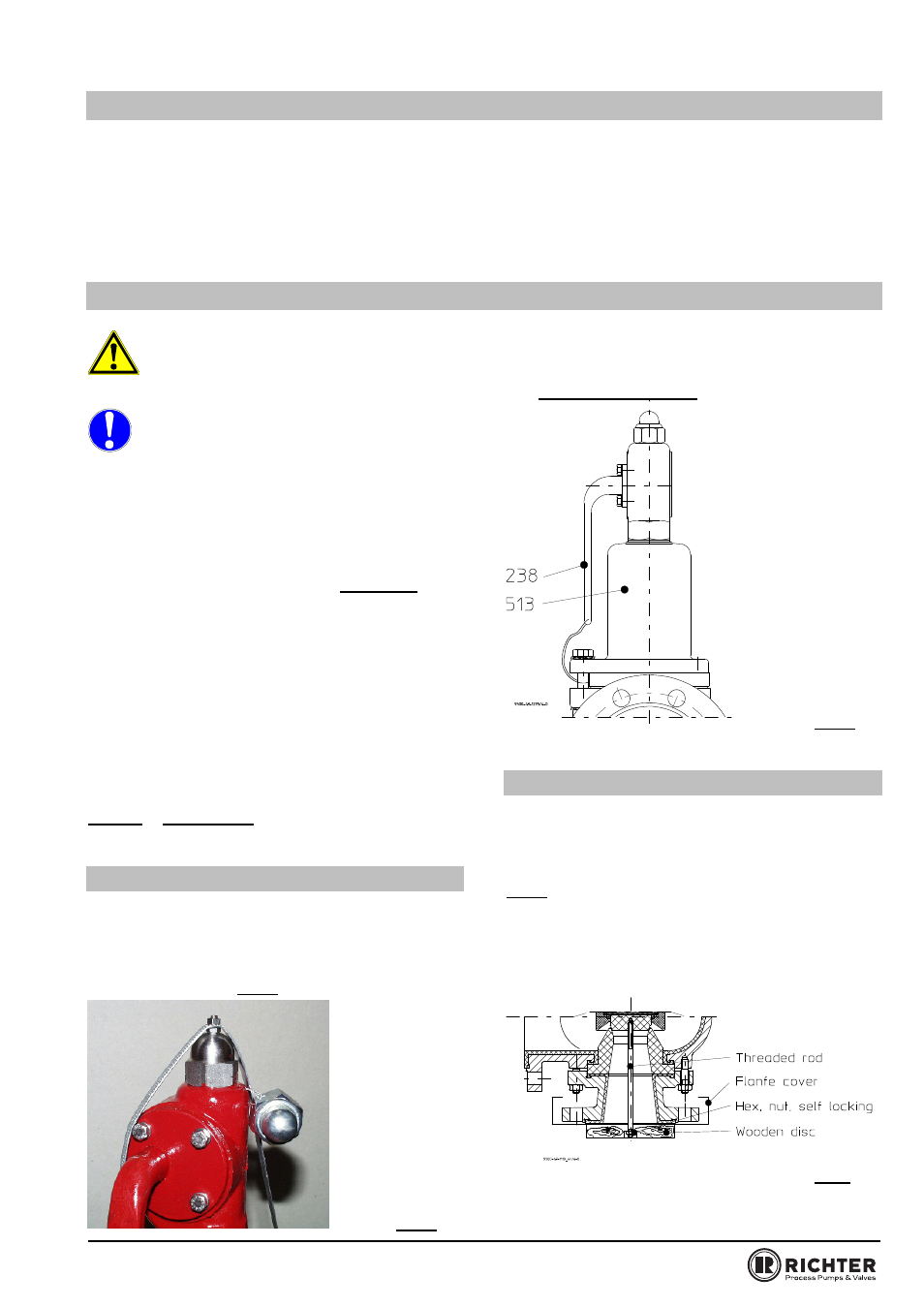

5.1 Transport securing for KSE/F

Safety vales with set pressures 0.5 bar are fitted at

the works with a transport fastening strap which holds

the stem in the axial direction and pre-vents damage

to the shut-off element as a result of the stem shaking

during transport. See Fig. 1.

Fig. 1

Remove the safety wire between the lifting lever 238

and one connection screw of the lifting cap 513 /body

100 prior to commissioning.

See Section 6.6 and Fig. 2.

Fig. 2

5.2 Transport securing for KSE -C

The threaded rod is screwed through the inlet nozzle

into the plug. It is inserted through the central bore of

the flange cover and screwed against the inlet flange

with a wooden disc and a self-locking hex. nut. See

Fig. 3.

The flange cover can only be removed when the

transport securing screw has been removed. This

ensures that it is only possible to install the valve

when the stem locking device has been removed.

Fig.3