7 tests, 1 lift, 2 test pressure – Richter KSE-C/F Series Safety Valves User Manual

Page 19: Tests, Lift, Test pressure, Series kse/f, kse-c/f

Series KSE/F, KSE-C/F

Page 19

9530-050-en

Revision 04

TM 7489

Edition 03/2009

Lowering the bellows onto the seat

For this purpose screw the adjusting screw 538

into the spring bonnet 513 until the spacer can be

freely moved.

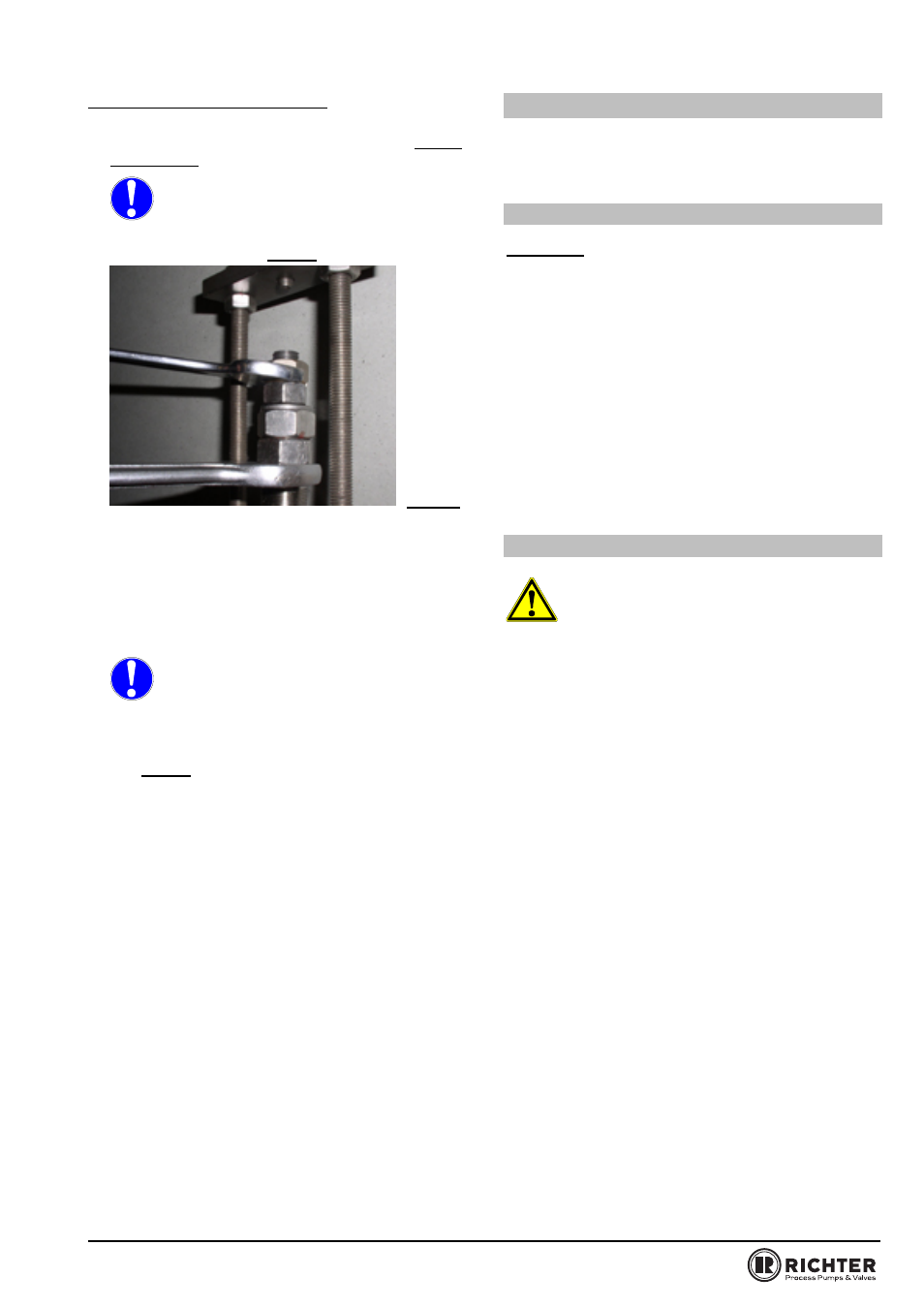

When tightening the adjusting screw 538,

hold the spindle 802 with a wrench on the

counter nut to prevent it from turning so

that the bellows 206 or the spring-type pin 939/1

are not damaged. See Fig. 25.

Fig. 25

Undo the counter nut and remove the spacer.

Now the valve can be set to the specified set

pressure.

Secure the spindle nut 534 and prevailing torque

type hexagon nut 929/1 on the end of the spindle

and counter against each other. Set the adjusting

screw 538 accordingly.

When screwing the prevailing torque type

hexagon nut 929/1 on or off the spindle

802 or when setting the adjusting screw

538, hold the spindle with a wrench on the counter

nut to prevent it from turning so that the bellows

206 or the spring-type pin 939/1 are not damaged.

See Fig. 25

9.7 Tests

Following the assembly of the valve, the lift and the

test pressure must be checked.

9.7.1 Lift

Lift check:

Remove the cap nut 935/1 from the lifting cap 535

and determine the height of the stem 802 up to the

upper edge of the lifting cap 535.

Determine this measurement in both the closed

and fully opened state.

Actuate the lifting lever 238 until the mechanical

travel stop can be felt.

The measurement can be made with a slide calliper

gauge and a depth indicator to DIN 862.

The lift is derived from the difference in the two

heights. It must be at least as high as the lift given in

the test certificate.

9.7.2 Test pressure

This test should take place on a test bench

with a neutral medium such as air or water.

Regarding their suitability and precision, the

employed pressure gauges must conform to the

requirements of current national regulations (in

Germany: e.g. VdTÜV data sheet "Safety Valve 100"

of the Association of the German Technical

Supervisory Boards).

All pressure tests should be carried out in

compliance with DIN EN 12266-1 or API 527.

It is recommended to use a bubble test with a 5

mm diameter hose positioned 50 mm below the

surface of water. The other end of the hose is

sealed to the outlet of the valve by means of a

plug.

To check the test pressure, the pressure in the

valve inlet is slowly increased until the valve

commences to open.

To check the reseating pressure, the pressure in

the valve inlet is slowly decreased until the valve is

bubble-tight.