Kse-c/f 80/100, 100/150, Series kse/f, kse-c/f – Richter KSE-C/F Series Safety Valves User Manual

Page 17

Series KSE/F, KSE-C/F

Page 17

9530-050-en

Revision 04

TM 7489

Edition 03/2009

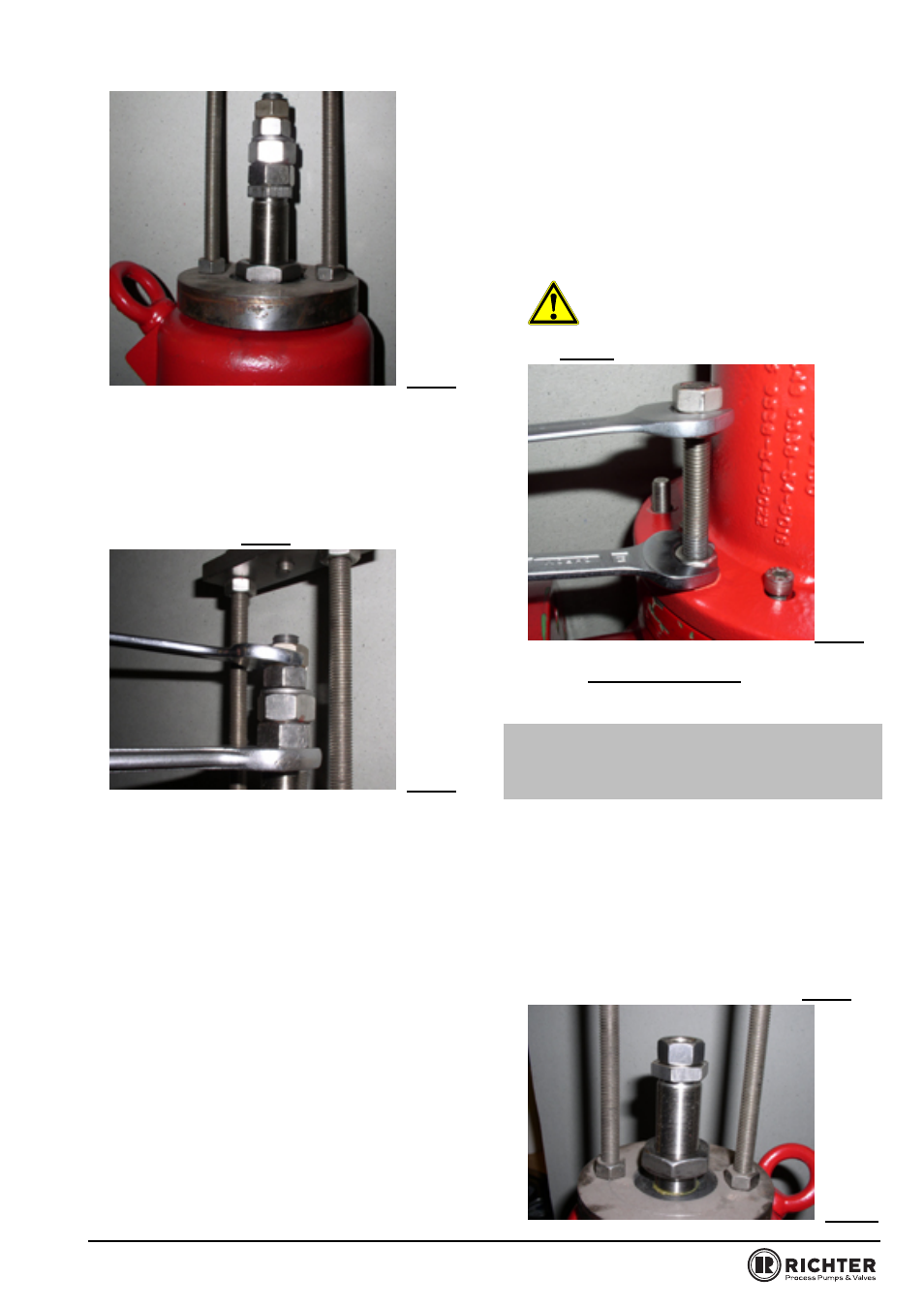

Fig. 17

In order to lift the plug 204 off the seat 205, raise

the entire spindle.

Undo adjusting screw 538 and turn it out of the

spring bonnet 513.

When undoing the adjusting screw 538, hold the

spindle with a wrench on the counter nut so that

the bellows 206 or the spring-type pin 939/1 are

not damaged. See Fig. 18.

Fig. 18

Unscrew hex. socket screw 914/1 off the pressure

ring 124.

Clean and grease the two threaded rods (approx.

150 mm) long / 180° offset).

Undo hex. nuts 920/2 to attach the spring bonnet

513 and thrust flange 117.

Remove complete upper section.

Press the bellows collar out of the guide of the

thrust flanges and then screw the bellows 206 off

the spindle 802.

Assemble the entire upper section (without

bellows) again with the body 100.

Screw hex. nut onto the threaded rod (up to flange

contact with spring bonnet 513).

Screw hex. nuts onto both ends of the threaded

rods and counter with more hex. nuts.

Tighten adjusting screw 538 (turn into the spring

bonnet 513) until the spacer sleeve is loose.

Undo hex. nuts at the end of the spindle and also

remove spacer sleeve.

Undo adjusting screw 538 and screw it out of the

spring bonnet 513.

The pressure spring 952/1 is only partially

relieved in this situation.

In order to completely relieve the spring, the two

nuts per threaded rod are evenly turned upwards

until the spring bonnet is loose.

It is imperative to secure the threaded

rods against turning (turning out of the

body flange) with a wrench on the

counter nut – Risk of accident!

See Fig. 19.

Fig. 19

The KSE/F can now be further dismantled. See

relevant Sections in 9.4 to 9.6.

9.8 Assembly

KSE/F 50/80, 80/100, 100/150

KSE-C/F 80/100, 100/150

Assembly the complete upper section with its

internals without the bellows 206, plug 204 and

lifting aid 237.

Grease the outside thread of the adjusting screw

and the inside thread in the spring bonnet (for

adjusting screw) well and, if difficult to screw, also

spray with torsion spray.

Mount a hex. nut on the free end of the spindle so

that when the complete unit is raised the internals

are held and they do not fall down. See Fig. 20.

Fig. 20