We’re here to help – RCBS The Grand User Manual

Page 13

10

7. Primers found on top of press:

Broken Transfer Arm. This is usually caused when the Primer

Drop Tube is filled with primers and the top primer wedges

between the Transfer Arm and the Drop Tube. The Charge

Bar pushes the Transfer Arm to the left and breaks off the

right side that is contained inside the Primer Tray. With the

right side of the Transfer Arm broken off, primers will

eventually push out the broken piece and also fall out onto

the top of the press instead of down into the Drop Tube.

We’re here to help!

If you have any questions, call RCBS Customer Service at

1-800-533-5000, Monday - Thursday, 6:30 a.m. to 3:00 p.m.

(CAUTION: Be sure to support underneath the Charge Bar to

keep from dropping the Bushings out the bottom.)

Install appropriate Powder and Shot Bushings, the Shot

Bushing is the larger diameter of the two and should be on the

right side, reinstall the Charge Bar. (NOTE: The windows on the

Charge Bar allow you to see what type of bushings that you

have installed, the windows should face the front of the press.)

Reinstall Charge Bar Locking Pin through the Index Shaft

Bracket and Charge Bar. (NOTE: Lowering the Handle slightly,

allows movement of the Push Rod, allowing the Locking Pin to

be installed through the Index Shaft Bracket easier.)

TROUBLESHOOTING

1. Hulls:

Split or crushed hulls are not to be used. Out of round

hulls may catch on Size Ring or Primer Seat Die. Return to

round before using.

2. Indexing:

The Case Holder Plate indexing is set at the factory. Should

adjustment become necessary, adjust the adjustment screw

up or down. Indexing can be affected if errant shot finds its

way into the Case Holder Plate or under the Indexing Arm

(see photo 44).

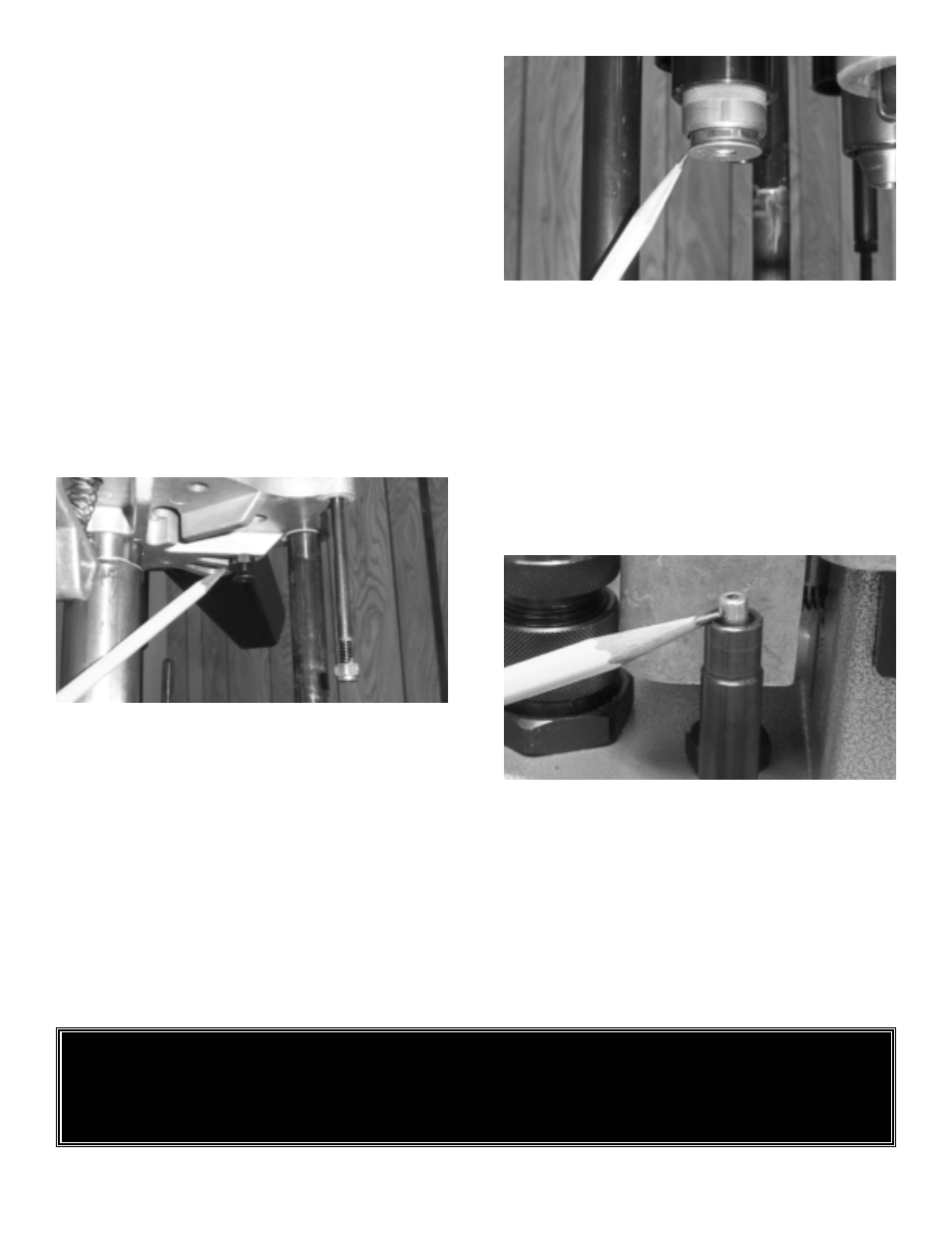

44

46

45

3. Adjusting the upper bushing of the size die will increase or

decrease the amount force used to push the hull from the

Size Die. Adjust so you feel the minimal amount of force to

size but enough to eject the spent primer and push the hull

from the Size Ring.

(see photo 45.)

4. Hull stuck in the Size Die:

Typically not enough spring pressure. Adjust the upper

bushing of the Size Die down to push the hull from the Size

Die. High base brass may require more hull ejection spring

pressure. If hull ejection pressure is at a maximum setting

and the hulls continue to stick in the Size Die, inspect Case

Holders for damage or this may be a sign that there is base

wad separation in the hull. Inspect the offending hull, if base

wad separation is noticed, discard hull. CAUTION: If this hull

is loaded, the base wad may separate when fired and lodge

in the barrel causing damage to the firearm and potential

injury to the shooter.

5. Primers do not transfer from Primer Tray to Drop Tube:

Remove Lock Pin from Primer Tray.

Primer Tray may not be seated properly on Drop Tube.

See

photos 16 & 17.

Charge Bar not making full and proper travel. The Handle

is not being cycled completely or check Index Shaft and

Brackets for wear or looseness.

Broken Primer Transfer Arm. (see

#

7 below)

6. Primer Tray fell off press:

Improperly seated or the Primer Shut Off Pin was not

inserted when single rounds were loaded. If the Primer Shut

Off Pin is not inserted, primers will continue to feed into the

Drop Tube, the Drop Tube fills with primers (@25) and works

the Primer Tray up and off the press

(see photo 46).

2429_RCBS Grand Instr 1/31/05 2:34 PM Page 13