RCBS The Grand User Manual

Page 12

9

43

POWDER AND SHOT BUSHING CHANGE

The Grand shot shell press uses replaceable powder and shot

bushings to control charge weights. Carefully check the charge

weights thrown as they can vary based on powder type, age of

powder and type of shot used.

Empty charge bar for bushing change. To change Powder or

Shot bushings, but staying with the same type of powder and

size of shot, move Hoppers to the OFF position. If you are

changing type of powder or shot, DRAIN hoppers first. You must

then remove the powder and shot left in the Charge Bar. With the

press clear of hulls, place a fired hull in station 3 and a fired hull

with a wad in Station 5. Lower the Handle, dropping the charges

in the charge bar. Raise the Handle completely, remove the hulls,

empty hulls and replace back into Stations 3 and 5. Lower and

raise the Handle once more. Remove and empty the hulls. Your

Charge Bar is now cleared. Remove the Charge Bar locking pin

and the slide to the right allowing changing of the Bushings.

6. Shot Drop and Wad Seating Station Adjustment

#

5 size

shot is the largest size The Grand will dispense. Larger shot

sizes must be weighed separately and manually put into the

hull prior to the Crimp Start station. Due to varying base wad

heights and design, as well as wad design, it may be

necessary to adjust the Lower Shot Tube to obtain proper

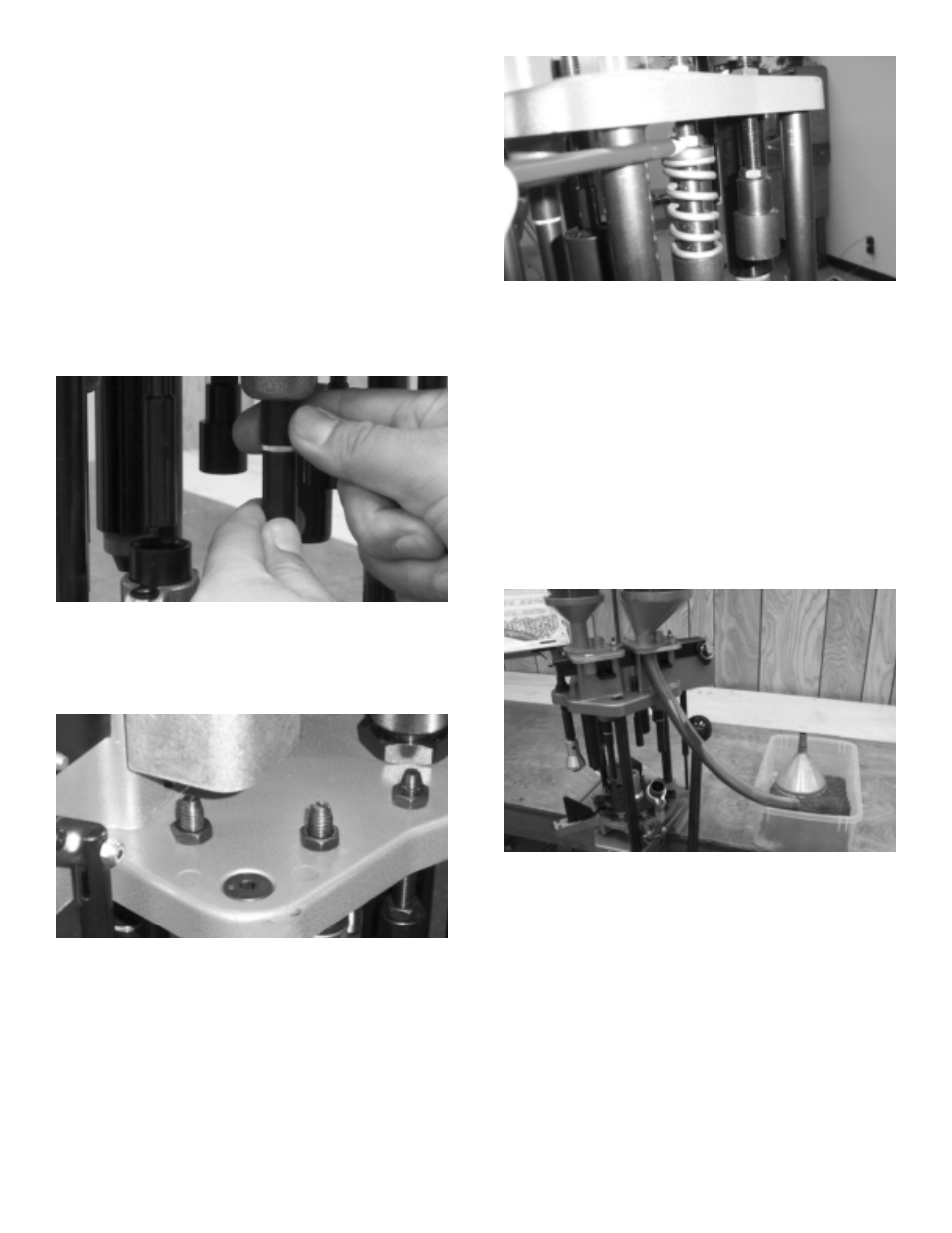

wad seating depth. Adjust by grasping the Upper Drop Tube

with the fingers of one hand and unscrew the Lower Drop

tube with the fingers of the other hand

(photo 40). Secure with

brass lock ring. Shot Shut Off Gate movement will typically be

from

1

/

4

" out to all the way in. For 12 gauge hulls with tapered

internal bases such as Winchester AA red or gray, Remington

STS or Nitro 27, etc., a longer Lower Shot Tube has been

provided to achieve proper wad seating depth. (NOTE:

Improper wad seating depth will cause hull collapse/buckling

or crimp problems at Station 7).

For proper wad seating, 20 gauge loaders need to adjust a

gap of

1

/

4

" to

5

/

16

" between the Upper and Lower Shot Drop

tubes.

40

7. Crimp Start Adjustment Crimp start is an up or down

adjustment. Loosen the top lock nut (A) and adjust Crimp

Start assembly up or down, retighten lock nut

(photo 41).

Too much Crimp Start can cause a bulge on the side at

the top of the hull during crimp. Not enough crimp start can

leave a hole in the center of your hull after crimp.

42

8. Crimp Adjustment Crimp is also an up or down

adjustment. The crimp depth is controlled by loosening lock

nut (B)

(see photo 41), adjusting the Crimp Die assembly,

up or down and retighten lock nut. If hulls bulge or collapse

during crimp, reduce crimping spring pressure. To reduce

crimp spring pressure, adjust nut (C)

(photo 42) up towards

the bottom of the Top Plate. If the crimp is concave or

dished, add spring pressure. If the crimp is peaked, reduce

crimp spring pressure and check that wad is seated to the

correct depth. (NOTE: If wads are not seated deep

enough, the shot column will be too high in the hull thus

causing problems with crimp.)

41

➞

A

➞

C

➞

➞

B

➞

B

D

9. Final Crimp Adjustment Final crimp is an up or down

adjustment to radius the end of the loaded round. Loosen

the top lock nut (D)

(see photo 41), adjust Final Crimp die

up or down and retighten lock nut.

10. Case Eject Adjustment The Press is preset for proper

case eject. Should adjustment become necessary, using a

5

/

16

" hex key wrench, loosen the socket head cap screw in

the top of the Eject Rod Holder, position the Case Eject

Arm to just clear the final crimp die and retighten the cap

screw. (CAUTION: Do not use the Case Eject Rod to try to

tighten the Eject Rod Holder!)

DRAIN SHOT AND POWDER HOPPERS

Place the flexible drain tube on the boss below the hopper you

wish to empty. Place a container beneath the drain tube. Rotate

the Hopper to the DRAIN position and the Hopper will empty in

a matter of seconds

(photo 43).

2429_RCBS Grand Instr 1/31/05 2:34 PM Page 12