RCBS Pro 2000 Progressive Reloading Press User Manual

Page 9

- 9 -

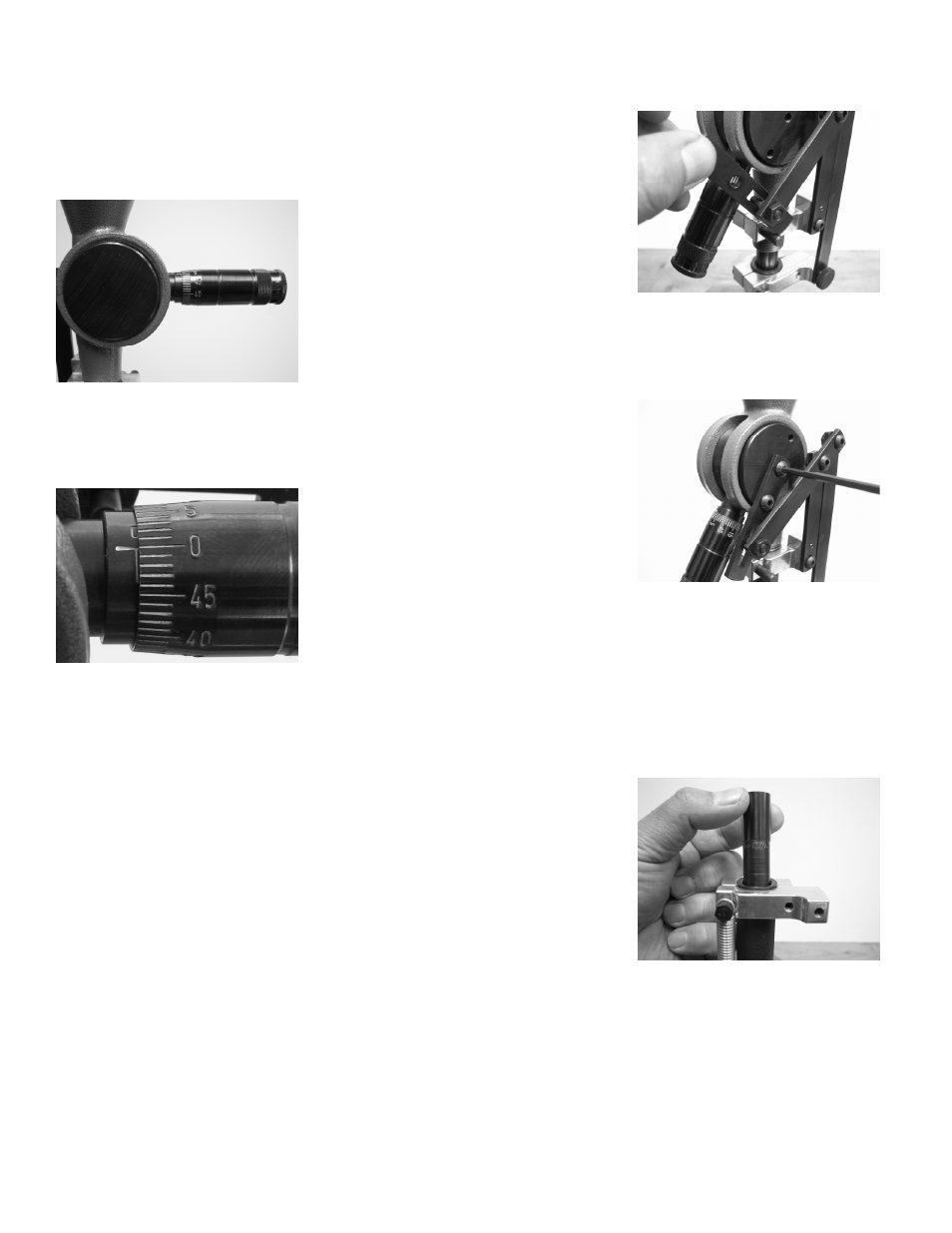

Next, slip the micrometer thimble over

the shank and secure it to the

metering screw using the setscrew

that is in the top of the thimble.

Holding the cylinder halfway through

its travel, see photo C, turn the

Micrometer down as far as it will go

until the metering screw stops against

the powder measure casting.

Photo C

Loosen the setscrew and adjust the

thimble position to set the Micrometer

at the "zero" reading. See photo D.

Photo D

Rotate the powder measure cylinder

to make sure the Micrometer

Adjustment Screw is not rubbing

against the casting. If it does rub the

casting, unscrew the Micrometer one

or two graduations. Then loosen the

setscrew and re-zero the Micrometer.

Tighten the setscrew. The Uniflow

Powder Measure with the Micrometer

Adjustment Screw is ready to use.

INSTALLING LARGE METERING

SCREW

Having determined how many

washers are required to properly

locate the index scale, remove the

Micrometer body from the large

powder measure cylinder. Drop the

metering screw into the powder

hopper, threaded end first. The screw

will drop into the hole of the cylinder

and the threaded end can be grasped

from the outside.

Holding the shank of the metering

screw, turn the body of the

Micrometer(with the correct number of

washers) onto the shank until the

threads of the body come in contact

with the cylinder. Release the shank

and thread the Micrometer body into

the powder measure cylinder. Make

sure the washers align in the counter

bore of the cylinder. Use the wrench

flats on the end of the body to tighten

the body securely.

Next, slip the Micrometer thimble over

the shank and secure it to the

metering screw using the setscrew

that is in the top of the thimble.

Holding the cylinder halfway through

its travel (see photo C) turn the

Micrometer down as far as it will go

until the metering screw stops against

the powder measure casting, Loosen

the setscrew and adjust the thimble

position to set the Micrometer at the

"zero" reading. See photo D.

Rotate the powder measure cylinder

to make sure the Micrometer

Adjustment Screw is not rubbing

against the casting. If it is rubbing,

unscrew the micrometer one or two

graduations. Then loosen the

setscrew and re-zero the micrometer.

Tighten the setscrew and the Uniflow

Powder Measure with the Micrometer

Adjustment Screw is ready to use.

The Micrometer Adjustment feature

allows the hand loader to record the

Micrometer reading for a specific

charge of a given powder. By using

the Micrometer, you can return to that

setting at a later date when the

charge is again being used. Although

the same setting will probably not give

exactly the same charge due to

changes in powder lot, humidity and

other variables, the Micrometer

setting will be very close and save the

hand loader considerable time.

POWDER MEASURE

INSTALLATION

Slip the slotted portion of cylinder link

over the drive pin. See photo E.

Photo E

Now install the cylinder link with two

10-32x3/8" socket head button

screws using the 1/8" Hex Key

Wrench. See photo F.

Photo F

Thread the Powder Die three full

turns into Station 3. Select the

correct powder bushing, small rifle

22-270, large rifle 7mm-45, or pistol.

Install bushings with the funnel end

up. See photo G. See Powder

Bushings in Diagram F on page 8 for

correct orientation.

Photo G

Install Powder Measure assembly

into Powder Die. See photo H.