RCBS Pro 2000 Progressive Reloading Press User Manual

Page 6

- 6 -

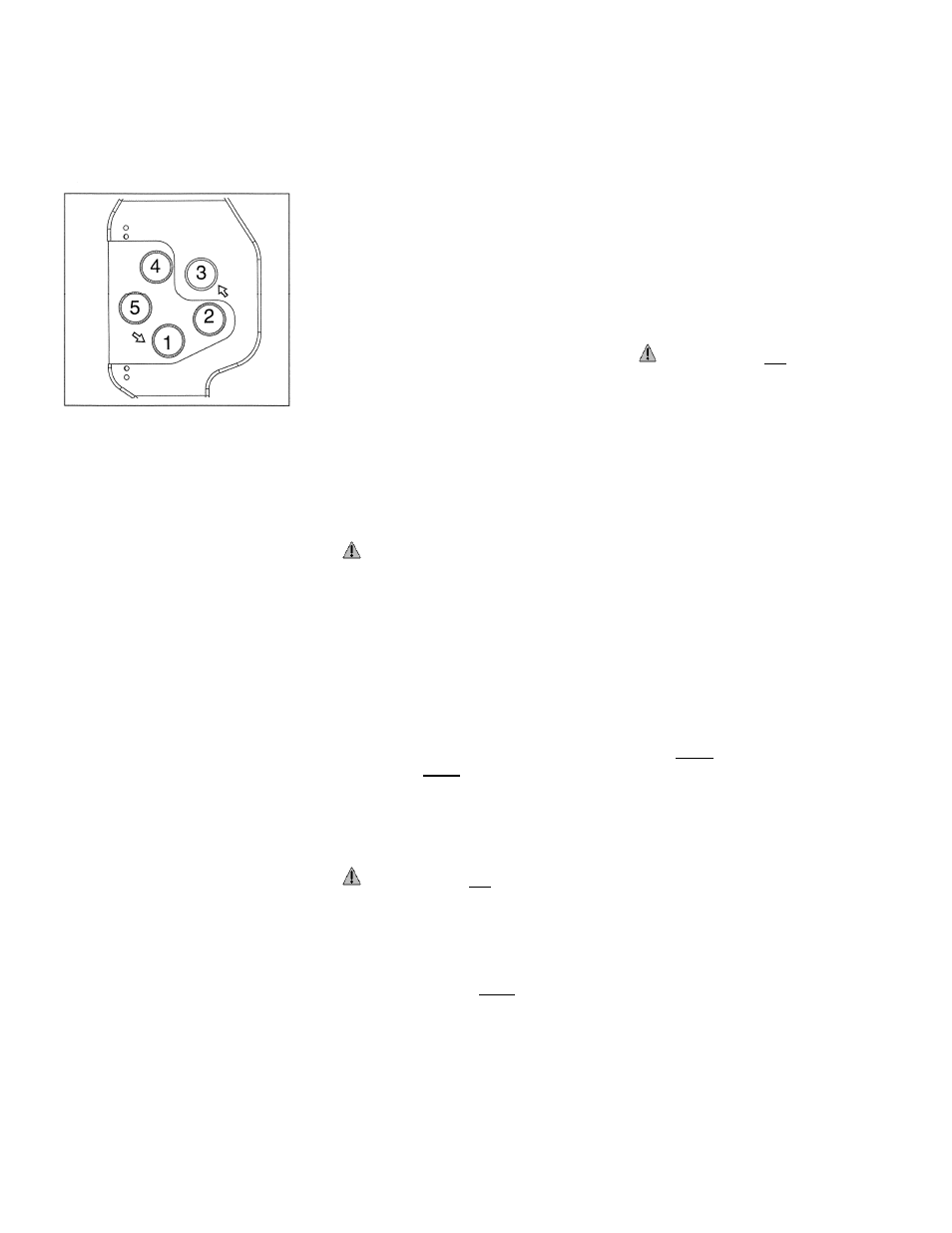

PRESS SET-UP

Refer to reloading Die instructions

and Powder Measure instructions for

individual adjustment and set-up. See

diagram for position and rotation.

Indexing is in a counter-clockwise

direction.

STATION SET-UP OPTIONS

Station 1:

1. Sizing Die

2. Lube Die is optional when

reloading bottleneck cartridges.

3. Decap Die: Size and expand in

Station 2 with an elevated

Expander Ball.

Station 2:

1. Expander Die for straight wall

cases.

2. No die for bottleneck cartridges.

3. Sizing Die if using Lube Die at

Station 1. This allows you to

elevate the Decap Rod and

Expander, which enhances the

expanding operation.

Station 3:

1. Powder charging. Refer to

Powder Measure instructions on

page 8-10.

Station 4:

1. Lock Out Die (optional for pistol

calibers 9mm and larger).

2. Powder Checker Die (optional,

for most rifle and pistol calibers).

3. Seat Die.

4. Bullet Feeder

Station 5:

1. Seat die or seat/crimp die

2. Crimp die (optional if you

choose to seat and crimp

separately).

DIE ADJUSTMENT

Standard die adjustments are listed in

this section. Refer to PRESS SET-UP

for die position. If you have questions

after reading these instructions,

please refer to the Die Instructions

included with your die set.

2-DIE SET FOR BOTTLENECK

RIFLE AND PISTOL CASES

The end of the expander ball must be

at least 3/16" inside the bottom of the

die. The Expander Ball and

Decapping pin are adjusted by

loosening the small lock nut at the top

of the die and turning the Expander-

Decapping Rod until the desired

setting is obtained. When the

Expander Ball is adjusted correctly,

the Decapping pin will protrude below

the bottom of the die just enough to

knock out the spent primer. The case

is sized (full length or neck), deprimed

and expanded in one operation. If

cast lead bullets are being used, you

will need an RCBS Neck Expander

Die as a second operation. This die

expands a sized rifle case neck to the

correct diameter and slightly flares

(bells) the case mouth for lead bullet

seating.

FULL LENGTH OR NECK SIZING

CAUTION: To prevent sticking

your cases in the sizing die, always

lube cases before sizing, unless using

a carbide sizing die.

Lower the handle and raise the ram to

the top of the stroke. Thread the

Sizing Die into the press until the die

touches the Shell Plate. Be sure all

play is removed from the press

leverage system. To do this, slightly

raise the handle to lower the shell

plate and, thread the die 1/8 to 1/4

turn further down so the press cams

over center. Set the Die Lock Ring

and you're ready to size.

BULLET SEATING WITHOUT

CRIMPING

CAUTION: Do not adjust the

Seater Die down against the shell

plate as it will distort or crush the

case.

These instructions are for seating the

bullet without crimping. To adjust the

Seater Die, place a sized case (no

primer or powder, this case becomes

a “dummy” or “setup” round), into the

Shell Plate at Station 5 and run it to

the top of the press stroke. Thread the

Seater Die down into the press until

you feel it touch the mouth of the

case. Back the die up one full turn

and lock the Die Lock Ring. This will

leave a gap between the bottom of

the die and the shell plate.

Raise the handle and re-insert the

case into Station 5. Place the bullet

onto the case mouth and slowly cycle

the handle to seat the bullet.

Measure the overall length of the

cartridge to check for proper bullet

seating depth. If the bullet is not

seated to the correct depth, adjust

the Bullet Seat Plug, up or down,

until the proper cartridge overall

length is obtained. This is a “trial and

error” operation. Once the proper

bullet seating depth is attained,

tighten the Seat Plug Lock Nut.

BULLET SEATING WITH

CRIMPING

CAUTION: Do not adjust the

Seater Die down against the shell

plate as it will distort or crush the

case.

First, follow the instructions for

BULLET SEATING WITHOUT

CRIMPING, before continuing with

this section.

We will now adjust the Seater Die to

crimp the case mouth into the bullet.

Insert the uncrimped “setup”

cartridge back into Station 5 and

lower the handle. With the uncrimped

cartridge up in the Seater Die, loosen

the Bullet Seat Plug Lock Nut and

unscrew(raise) the Bullet Seat Plug

several turns. Loosen the Die Lock

Ring and thread the Seater Die body

down until you feel it touch the mouth

of the case.

Raise the handle slightly to lower the

cartridge and adjust the Seater Die

body down another 1/8 of a turn.

Lower and then raise the handle to

run the cartridge back into the Seater

Die. Check the crimp. If more crimp

is desired, repeat the preceding step

by adjusting the die downward

another 1/8 of a turn. This is a “trial

and error” operation. Typically, you

will not lower the Seater Die body

down more than one-half a turn for

proper crimp. After you are satisfied

with the crimp, tighten the Die Lock

Ring.

Insert the “setup” cartridge back into

Station 5 and lower the handle. To

re-set for cartridge overall length,

thread the Bullet Seat Plug down

until it firmly touches the bullet.

Tighten the Bullet Seat Plug Lock

Nut.

The Seater Die is now properly

adjusted to seat the bullet and crimp

in one operation.