RCBS Pro 2000 Progressive Reloading Press User Manual

Page 8

- 8 -

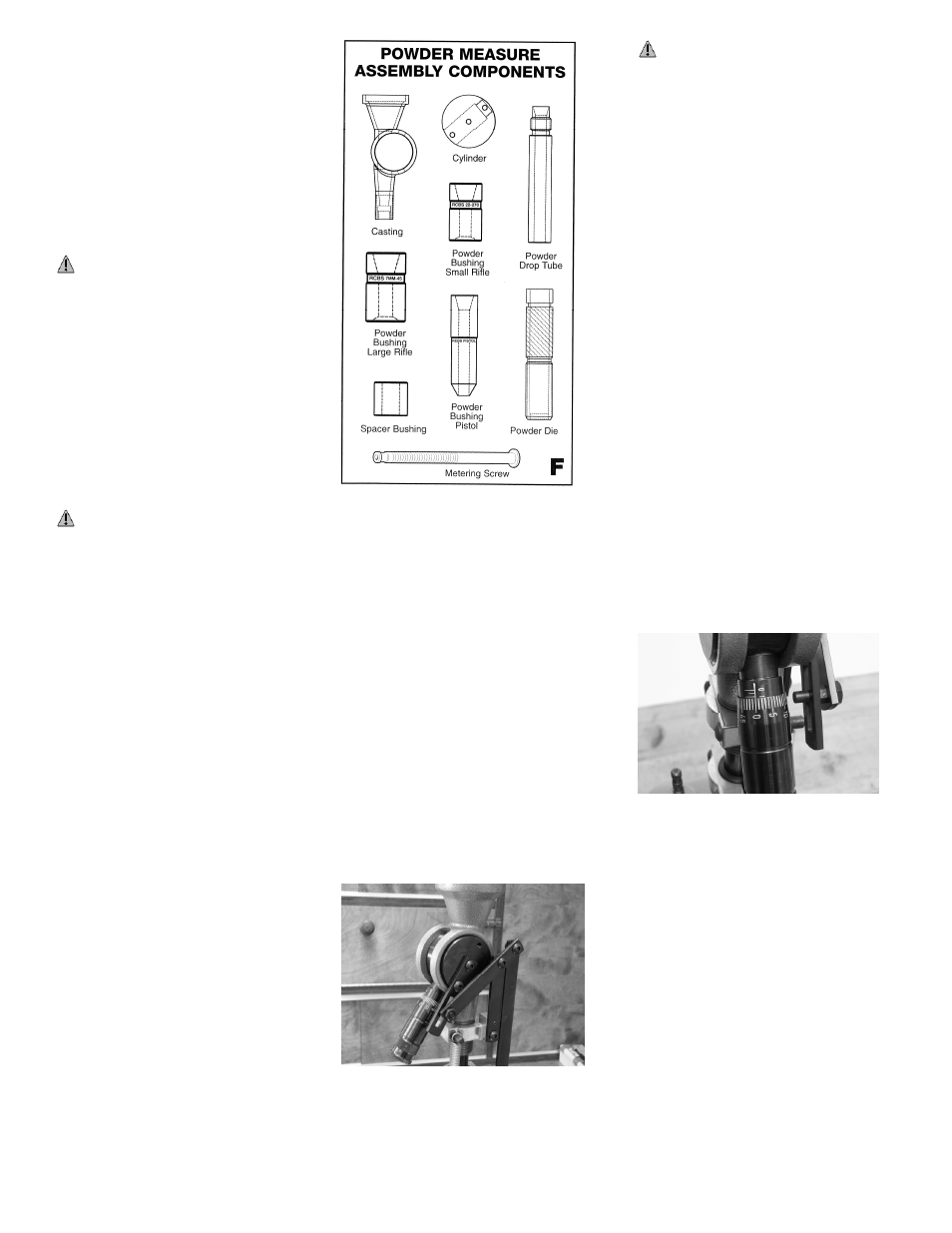

POWDER MEASURE

A powder measure is basically a

device which measures powder by

volume, not weight. However, before

you start throwing a given charge with

a powder measure, the first charge

must always be weighed on a powder

scale to arrive at the desired charge.

Accurate powder measure charges

will also depend upon the size and

uniformity of the powder kernels used.

DANGER: DO NOT use the

Uniflow Powder Measure with

black powder!

Helpful Tip: The consistency of the

powder and static electricity are

causes of erratic powder charges.

Slowly roll the powder container

several times to homogenize it before

pouring it into the powder hopper.

Static electricity can be reduced by

wiping down the powder hopper with

a clothes dryer sheet.

CAUTION: All internal components

of the powder measure assembly

must be thoroughly cleaned of rust

preventatives applied at the factory.

Failure to do this will cause powder

charges to be inconsistent and

provide erratic performance of your

reloads. See Diagram F for the

following items that must be clean

and dry before use:

• Casting

• Cylinder

• Metering Screw

• Powder Die

• Powder Bushings

• Spacer Bushings

• Powder Drop Tube

POWDER MEASURE ASSEMBLY

COMPONENTS-

A dependable powder scale should be

used to set the first charges in the

powder measure. It is not necessary

to empty the powder hopper each

time you change charges unless a

different powder is required.

POWDER MEASURE ASSEMBLY

Choose the correct cylinder.

•

The large cylinder throws charges

of ~5-99 grains.

•

The small cylinder throws charges

of ~2 to 50 grains.

To install the cylinder, make sure the

screw holes are oriented facing

toward the Linkage Assembly before

you slide it into the Main Casting. See

Photo A.

Photo A

CAUTION: DO NOT leave

powder in the measure, as it will

deteriorate and may clog and jam the

measuring cylinder and etch the

powder hopper.

Included with the Pro 2000 is a small

and large Micrometer Adjustment

Screw for the Uniflow Powder

Measure. To allow alignment of the

linear scale index, in any position the

operator chooses, three thin washers

are included. The only way to

determine the number of washers

needed is by trial and error. Each

washer provides a 90 degree,

counter-clockwise, rotation of the

body. To set the index lines in the

position you wish, first thread the

Micrometer body into the cylinder

until snug. Note the position of the

index lines. If the alignment is not

satisfactory, remove the body and

add a washer to the body over the

threads.

Thread the body into the cylinder

again, and note the change in the

location of the index.

By adding or deleting washers, you

will be able to set the index

according to your preference. See

photo B.

Photo B

INSTALLING SMALL METERING

SCREW

Having determined how many

washers are required to properly

locate the index scale, remove the

Micrometer body from the small

powder measure cylinder. Thread the

small metering screw into the

Micrometer body ten turns. Next,

insert body and metering screw

through the front of the powder

measure casting and into the

cylinder. Screw the body into the

powder cylinder (with correct number

of washers). Make sure the washers

align in the counter bore of the

cylinder. Use the wrench flats on the

end of the body to tighten the body

securely.