Kenco Engineering Thermal Differential Switch User Manual

Page 2

Page 2

GENERAL DESCRIPTION

The Series KTD Thermal Differential Switch is the state-of-the-art in gaseous and liquid flow switching or liquid level /

interface control. Flow or level detection is accomplished by using a high resolution

thermal differential technique. The

standard sensor wetted parts are of durable 316L series stainless steel, all welded construction with no moving parts. The

switch is easy to install and adjust, giving reliable, low maintenance performance in the most demanding applications.

PRINCIPLE OF OPERATION

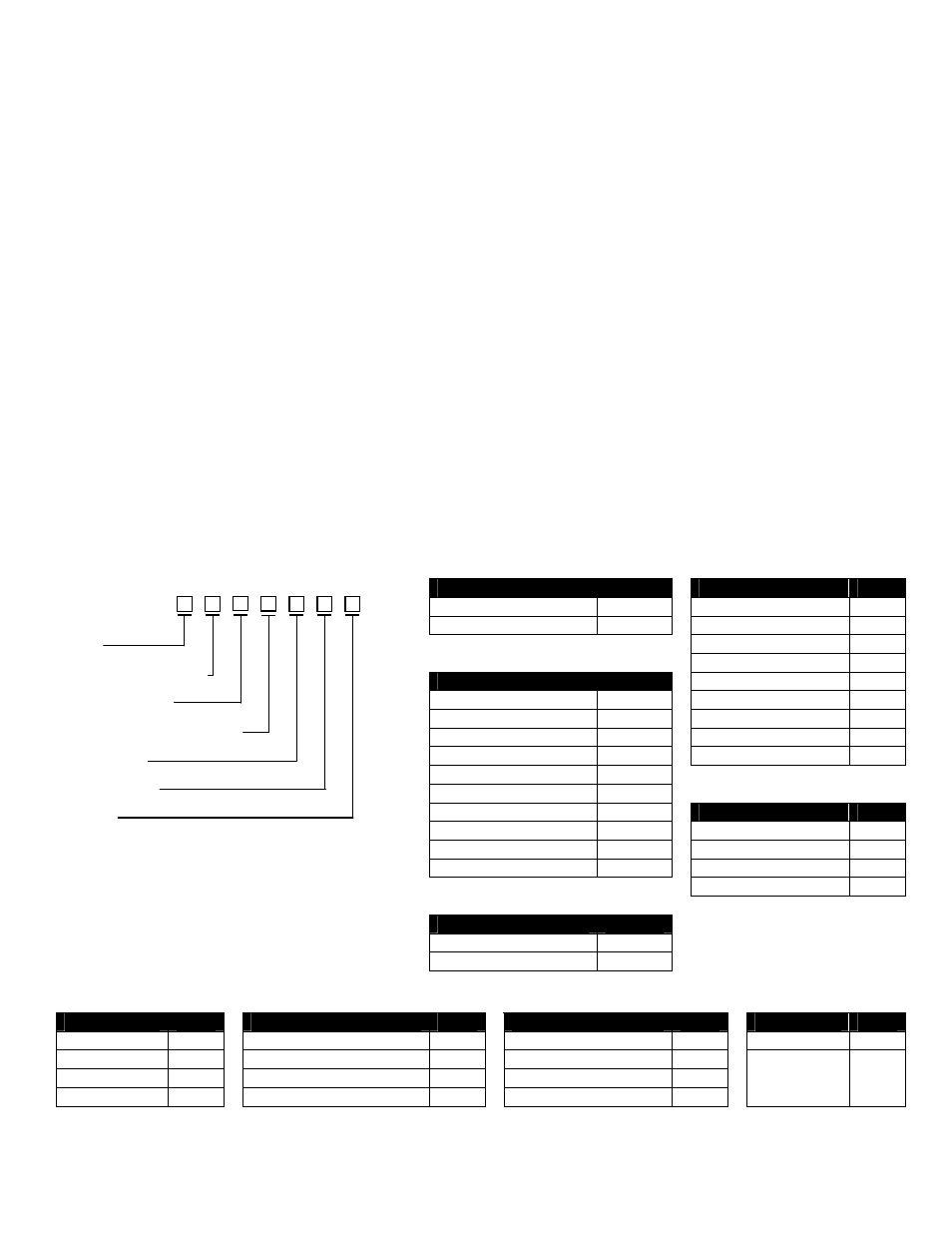

MODEL DESCRIPTION

- - - - - -

Model

Process Connection

Sensor Material

Insertion Length (Inches)

Input Power

Configuration

Options

Options

Options (cont.)

Options (cont.)

Options (cont.)

Description

Code

Description

Code

Description

Code

Description

Code

No Options

00

Extended Neck

EN

Additional Cable

CA

SS Tag

TG

RTD Output

RT

*High Temp (850ºF)

HT

Variable Insertion

VI

Live Tap

LT

*Medium Temp (572ºF)

MT

Factory Calibration

CB

CE Approved

CE

Explosion-proof Window

XW

Thermocouple Output

TO

Sensor

Installed in

Tee

TE

* Remote Mounting Required

Model

Sensor Material

Description

Code

Description

Code

Level Switch

KTDL

316L SS

S6

Flow Switch

KTDF

304 SS

S4

304L SS

SL

Process Connection

Hastelloy-B

HB

Description

Code

Hastelloy-C

HC

½” NPT

050

Inconel 600

IO

¾” NPT

075

Monel

MN

1” NPT

100

Alloy-20

A2

1½” Sanitary

3A1

Special Material

SM

1” 150# ANSI Flange

RA1

2” 150# ANSI Flange

RA2

Input Power

1” 300# ANSI Flange

RB1

Description

Code

2” 300# ANSI Flange

RB2

110 Vac

110

Low Flow Sensor

LFS

220 Vac

220

Special Connection

SPL

24 Vdc

24D

24 Vac

24A

Configuration

Description

Code

Insertion Length

Integral Mounting

LE

002.00 (standard)

Remote Mounting

RE

000.50 – 120.00 (optional)

The Series KTD Thermal Differential Switch uses a thermal differential technique to measure liquid level or interface

by sensing changes in the thermal heat transfer characteristics of the media where it is located. The sensor consists

of a pair of matched Resistance Temperature Detectors (RTD’s) encased in twin 316 series, stainless steel tubes.

One RTD is self-heated using a constant DC current. The other sensor is unheated and provides an accurate ambient

process temperature reference. The thermal differential created between the heated and reference RTD pair is

a function only of the media with which the sensor is in contact. The differential is greatest when no liquid is present

(dry condition) and decreases as liquid quenches the switch sensors (wet condition).

Hydrocarbons generally have lower heat-transfer characteristics than aqueous-based materials so liquid-liquid

interface detection is possible. In general, any two media will exhibit some difference in heat-transfer characteristics.

Thus, the switch can be calibrated to detect the interface between two immiscible liquids.

This switch can also be used as a no-flow or a low flow switch. In this case the actual flow of the liquid or gas

provides the cooling effect. In other words, the lower the flow rate the greater the temperature differential between the

(2) RTD’s.

Solid-state electronics transform the temperature differential into a voltage that is compared to a control voltage to

actuate a relay and indicate a change in state (wet vs. dry). The instrument head at the top of the unit contains the

Switch electronics board which is easily removable from the instrument head so that field wiring can be connected to

the field terminal block.