Kenco Engineering 17000 Sight Tube Replacement User Manual

Kenco Engineering Sensors

P.O. BOX 470426, TULSA, OK 74147-0426

PHONE: (918) 663-4406 ● FAX: (918) 663-4480

http://www.kenco-eng.com

● e-mail:

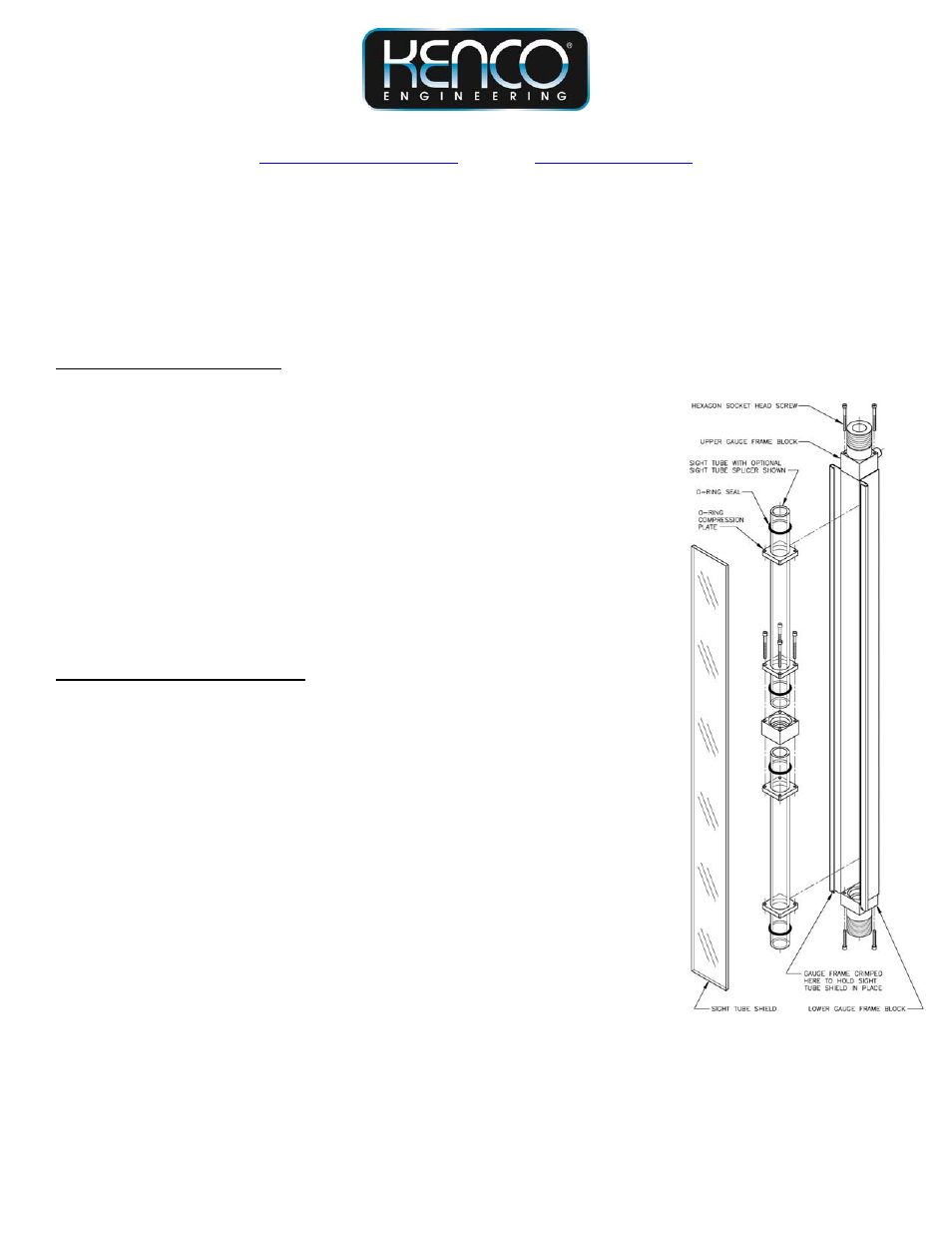

KENCO MODEL 17000 WITH METAL PROCESS CONNECTIONS

(SIGHT TUBE REPLACEMENT INSTRUCTIONS)

Do not proceed with any maintenance unless gauge has been relieved of all pressure or vacuum and has been allowed to

reach ambient temperature. Gauge should also be flushed out to remove any hazardous liquids before handling if possible.

Removal of sight tube is a follows:

Remove existing sight tube shield by bending crimped portion of gauge frame on lower end

away from shield so it can easily slide out.

Remove hexagon socket head screws on each end of gauge holding O-ring compression

plates in place.

Push sight tube up into upper gauge frame block as far as is required to enable lower end of

sight tube to swing out from inside lower gauge frame block.

Carefully lower sight tube out of upper gauge frame block.

Note: If sight tube has a splicer, extra care should be taken so sight tube assembly

does not come apart.

Remove O-ring compression plates and O-ring seals from sight tube and discard O-rings.

Installation of sight tube is as follows:

Assemble sight tube splicer to sight tube as shown if one exists. If sight tube splicer body is

metal, there are (2) Teflon O-rings that will need to be installed between ends of sight tube and

sight tube splicer body to avoid sight tube contact with metal sight tube splicer body.

Note: Be sure to alternate back and forth between screws while tightening to ensure

that O-ring compression plates are tightened down evenly.

Slide O-ring compression plate onto each end of sight tube.

Slide new O-ring seal onto each end of sight tube.

Ensure that screw holes in O-ring compression plates are oriented the same as screw holes in

gauge frame end blocks.

Push upper end of sight tube into hole in upper gauge frame block as far as is required to

enable lower end of sight tube to swing over and into hole in the lower gauge frame block.

Install hexagon socket head screws into blocks on each end of gauge and thread into holes in

O-ring compression plates and tighten securely.

Note: Be sure to alternate back and forth between screws while tightening to ensure

that O-ring compression plate is tightened down evenly.

A-68931

(Rev. #)

[12-11-13]