Kenco Engineering KLCM User Manual

Kenco engineering company

KENCO ENGINEERING COMPANY

P.O. BOX 470426 TULSA, OK 74147-0426

PHONE(918) 663-4406 FAX: (918) 663-4480

www.kenco-eng.com

e-mail:[email protected]

INSTALLATION INSTRUCTIONS FOR MODEL KLCM OIL LEVEL CONTROLLERS WITH ADAPTERS

(INCLUDING HIGH PRESSURE MODELS)

Note: For fire safe oil level controllers (LCM-FS) see additional instructions in this work sheet covering installation of fire safe

valves.

I. SWITCH SPECIFICATIONS:

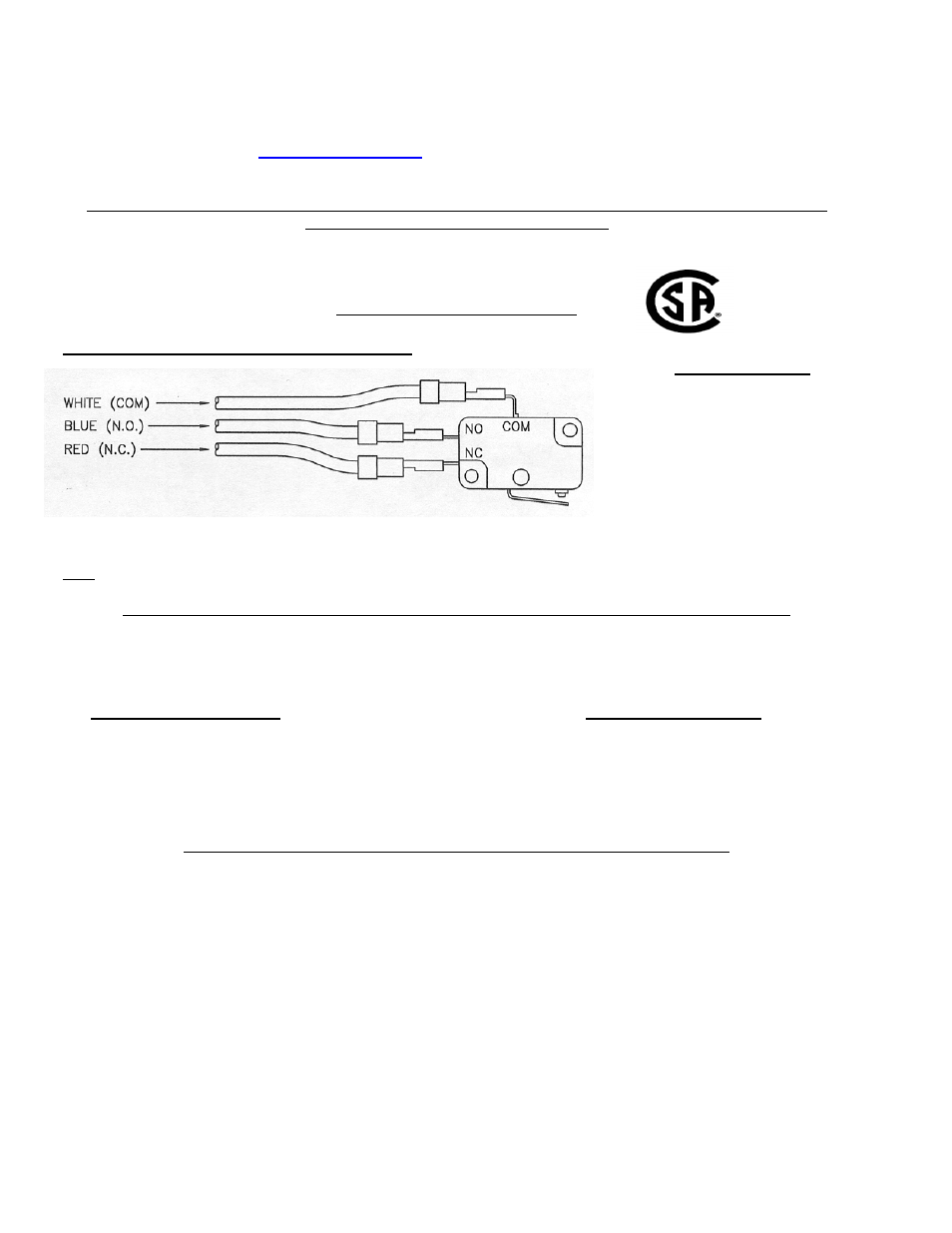

Figure 1: Model LCM Switch Wire Color Code

Note: Switch trip point is factory set at a ¾” drop . For adjustment instructions, please consult the factory.

II. INSTALLATION AND MAINTENANCE INSTRUCTIONS FOR OIL INLET VALVE:

•

Connect the oil supply line to the oil inlet on the oil level controller. The minimum recommended supply line is ¾” I.D. The

supply line must be clean and it is recommended that it be flushed with solvent before installation.

•

Connect the oil supply line to the oil supply tank. If there is no existing valve at the tank or the existing supply outlet, a shut-off

valve should be placed in the line to prevent oil loss when cleaning the inlet screen or filter.

•

For high pressure models HP-A, pressure range must be between 5 psi and 34 psi. For high pressure units HP-B , pressure

range must be between 35 psi and 70 psi.

•

The oil inlet valve is adjusted to maintain the oil level at the center of the sight glass. Low or high levels are often caused by

two problems:

1. Excessive oil inlet pressure, which will cause the unit to overfill.

2. Improper equalizing lines between the crankcase and the controller will also result in improper levels.

Note: Low pressure models require a minimum of 2’ of head pressure and a maximum of 15’ of oil inlet head pressure.

III. INSTALLATION INSTRUCTIONS FOR UNITS WITH ADAPTERS:

OIL LEVEL CONTROLLERS WITH

–1

(Clark MA & CFA)

–2

(Clark HMB & TMB),

-3

(Clark RA, HRA, HBA, HCA, HLA,

TLA),

-6

(Cooper-Bessemer GMW),

-7

(Cooper-Bessemer GMV),

-8

(Cooper-Bessemer GMX),

-16, -16-R, -16-6.25

(Cooper-

Bessemer BMV & 275) AND FS OPTIONS

•

Remove the visual oil gauge assembly from the engine and replace it with the oil level controller and adapter assembly supplied

with a gasket and mounting bolts when applicable.

OIL LEVEL CONTROLLERS WITH

–4

(Ingersoll-Rand SVG & KVS),

-5

(Ingersoll-Rand KVG) AND FS OPTIONS

•

Remove the visual oil gauge assembly from the engine and replace it with the oil level controller and adapter assembly supplied

with a gasket and mounting bolts when applicable.

•

If an equalizing exists for the engine sight glass and detach the equalizing line from the sight glass while still attached to the

engine.

•

Install the oil controller and then reattach the equalizing line to the vent located at the top of the adapter.

Note: It is important to insure that there are no loops in this line for it must be trap free and self draining.

Electrical Ratings:

10 AMP, 125/250 VAC

0.5 AMP, 125 VDC

0.25 AMP, 250 VDC

1/8 HP, 125 VDC

¼ HP, 250 VAC

125 VAC “L”Lamp Load

Circuitry: Single Pole Double Throw

Class III,

Type 4