Kenco Engineering 512 (old style) User Manual

Kenco engineering company

KENCO ENGINEERING COMPANY

P.O. BOX 470426 TULSA, OK 74147-0426

PHONE(918) 663-4406 FAX: (918) 663-4480

www.kenco-eng.com

e-mail:[email protected]

INSTALLATION INSTRUCTIONS FOR MODEL 512 OIL LEVEL CONTROLLERS WITH ADAPTERS

Note: For fire safe oil level controllers (512-FS) see additional instructions in this work sheet covering installation of fire safe valves.

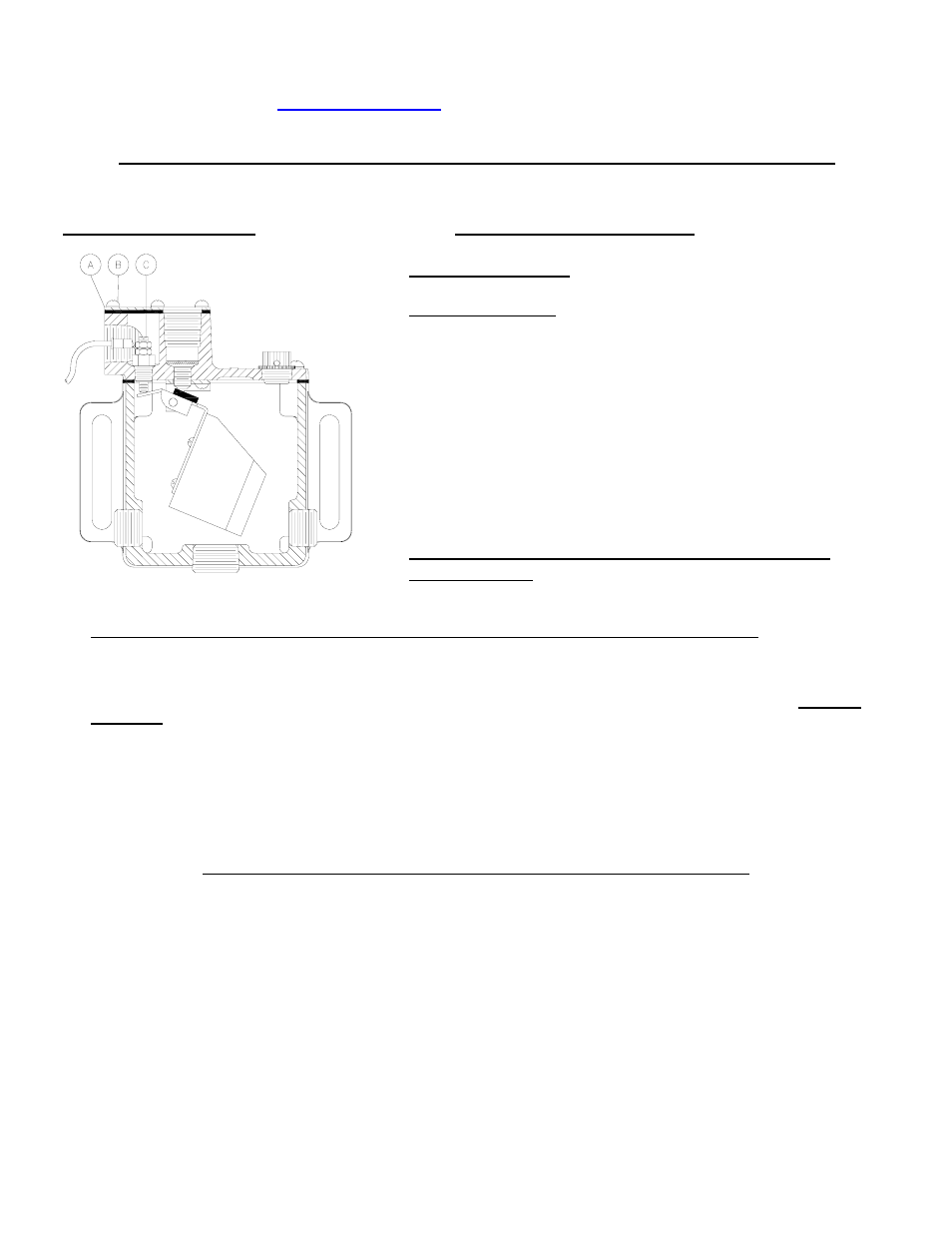

Figure 1- Side View of 512

I.

SWITCH

SPECIFICATIONS

II. INSTALLATION AND MAINTENANCE INSTRUCTIONS FOR OIL INLET VALVE:

•

Connect the oil supply line to the oil inlet on the oil level controller. The minimum recommended supply line is ¾” I.D. The supply

line must be clean and it is recommended that it be flushed with solvent before installation.

•

It is recommended that the oil supply line is connected using hose barb or tube fittings, using a reliable thread sealant. Do not use

Teflon tape.

•

Connect the oil supply line to the oil supply tank. If there is no existing valve at the tank or the existing supply outlet, a shut-off valve

should be placed in the line to prevent oil loss when cleaning the inlet screen or filter.

•

The oil inlet valve is adjusted to maintain the oil level at the center of the sight glass. Low or high levels are often caused by two

problems:

1. Excessive oil inlet pressure, which will cause the unit to overfill.

2. Improper equalizing lines between the crankcase and the controller will also result in improper levels.

Note: 512 models require a minimum of 2’ of head pressure and a maximum of 12’ of oil inlet head pressure.

III. INSTALLATION INSTRUCTIONS FOR UNITS WITH ADAPTERS:

OIL LEVEL CONTROLLERS WITH

–1

(Clark MA & CFA)

–2

(Clark HMB & TMB),

-3

(Clark RA, HRA, HBA, HCA, HLA, TLA),

-

6

(Cooper-Bessemer GMW),

-7

(Cooper-Bessemer GMV),

-8

(Cooper-Bessemer GMX),

-16 , -16-R, -16-6.25

(Cooper-Bessemer BMV

& 275) AND FS OPTIONS

•

Remove the visual oil gauge assembly from the engine and replace it with the oil level controller and adapter assembly supplied with

a gasket and mounting bolts when applicable.

OIL LEVEL CONTROLLERS WITH

–4

(Ingersoll-Rand SVG & KVS),

-5

(Ingersoll-Rand KVG) AND FS OPTIONS

•

Remove the visual oil gauge assembly from the engine and replace it with the oil level controller and adapter assembly supplied with

a gasket and mounting bolts.

•

If the visual oil gauge was vented back to the engine crankcase, remove the vent from the top of the adapter and tie it back to the

crankcase with tubing.

Note: It is important to ensure that there are no loops in this line for it must be trap free and self draining.

Switch Specifications: Case to Ground: 2 AMP, 30 VAC/VDC

Switch Adjustment: Switch adjustment is not recommended.

Improper setting may result in damage to engine. Switch is

factory set at ½” drop. If adjustment for the application is

necessary, refer to figure 1 and follow these instructions:

• Remove the cover of the condulet housing (A) by

unscrewing the 6 screws(B).

• Rotate the slotted set screw(C) counter-clockwise to lower

the switch trip point 3/16”.

• Rotate the slotted set screw(C) clockwise to raise the

switch trip point to a maximum of ½”.

• Attach the wire from the controller to the low tension

terminal on the magneto.

NOTE: The switch is not factory adjusted for proper

shutdown level.