HF scientific Micro200BW Turbidimeter - 0 -1000 NTU User Manual

Page 39

Page 25

MICRO 200 BW 0 - 1000 NTU (5/05)

Rev. 3.1

B. START UP

Before placing the MICRO 200 BW on line we recom-

mend that you standardize the instrument. The follow-

ing sections describe the required procedures.

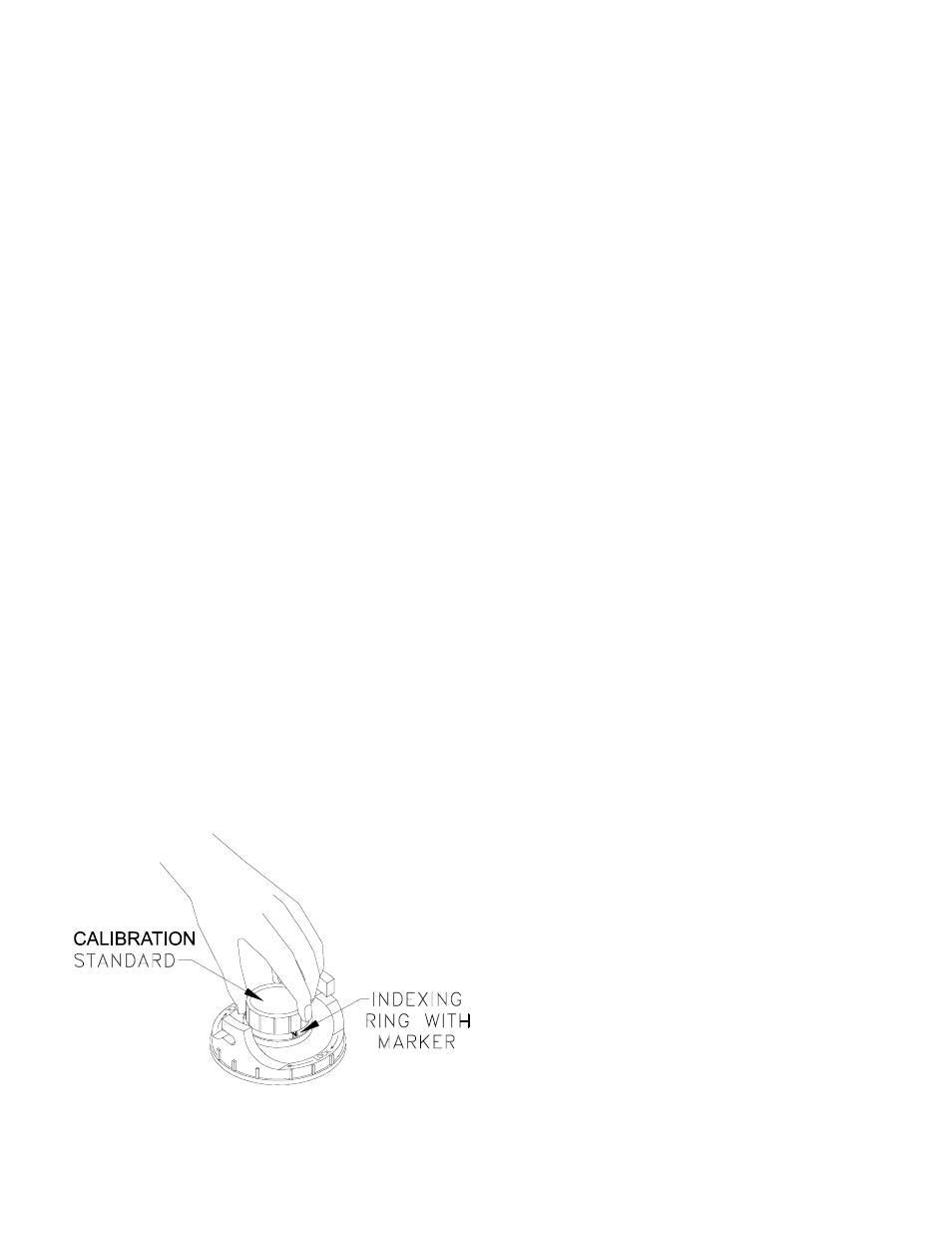

1. Indexing

The United States Environmental Protection Agency

(U.S. EPA) recommends that cuvettes used for instru-

ment calibration or sample measurement be indexed.

To comply with U.S. EPA standards, the MICRO 200

BW includes an Indexing Ring for quick and repeatable

indexing of the refernce standard.

To index the calibration standard you must be in the

calibration menu. Observe the top center (current

frequency) reading while performing the following steps:

a. Slowly rotate the standard, inside the optical well,

one complete revolution (360°). While rotating the

standard slowly, observe the measured turbidity

and locate the position of the cuvette having the

lowest reading.

b. With the calibration standard positioned at the

location having the lowest turbidity reading, install the

Indexing Ring over the cap on the standard so that the

pointer of the Indexing Ring faces directly forward.

When using the standards in the future, always insert the

standard so that the pointer of the indexing ring faces

forward. Slowly rotate the standard back and forth

about 5° to find the lowest point. The standard is now

indexed and ready for use.

Figure 9 shows a calibration standard being indexed.

NOTE: This Calibration Standard is only Indexed to

the Turbidimeter for which it was aligned.

Figure 9

Reference Standard Indexing

2. Standardizing

The reference standard (cuvette) supplied with the

MICRO 200 BW is a pure liquid sealed in glass. It has

a value of 0.02 NTU.

Standardization is performed in the calibration menu

see page 18 for more details. While in the calibration

menu perform the following operations:

a. Place the Reference Standard in the Optical Well.

b. Index the Reference Standard as previously de-

scribed.

c. Allow a few seconds for the standard to stabilize.

d. Press the F1 button to accept the frequency.

NOTE: This operation “calibrates” the .02 NTU refer-

ence standard in the range of interest. If both

ranges maybe used this operation should be

performed on both ranges.

CAUTION: Avoid scratching the surface of the cu-

vette. Keep the cuvette surface clean and

free of dust. A scratched or dirty and

dusty cuvette will cause analysis error.

For instructions (See: V. ROUTINE

MAINTENANCE).

IV. ROUTINE OPERATION

A. CONTINUOUS MONITORING FLOW

THROUGH UNIT

The standard flow through unit supplied with the in-

strument is designed to operate at pressures up to a

maximum of 60 p.s.i. (414 kPa or 4.22 kg/cm

3

) and

temperatures to a maximum of 122° F (50° C) fluid

temperature. Flow rates through the unit can be ad-

justed from 0.5 gpm (200 ml/min) to a maximum of

approximately 1.5 gpm (5.7 liters/minute). The speed

of sensing turbidity changes will depend on the length

of the take-off line, the diameter of the take-off line,

and the flow rate or velocity through the take-off line.

By using a high flow rate and keeping the lines small,

approximately 3/16 inch (4.8 mm) I.D. and relatively

short length, the response time is kept to a minimum.

Consult HF scientific, inc. when unusually long con-

nections are required.

Depending on the type of fluid being monitored, a

pressure drop through the line can cause gas or air to

come out of solution and form bubbles which will

create errors in the turbidity measurements. This can be

prevented by creating a slight back pressure on the