Pressure sensitive mounting - precoat - front, Tips, Custom application notes – GBC 64C User Manual

Page 35: Tips for custom application #1

Page 6-11

SPIRE II Series – Installation and Operating Instructions

p

ressure

s

ensItIve

m

ountInG

-

p

recoat

- F

ront

Use this process to mount a graphic to a precoated

substrate.

Examples include POP signage, legal graphics,

photographs, and presentations.

MR

MR

U

U

R

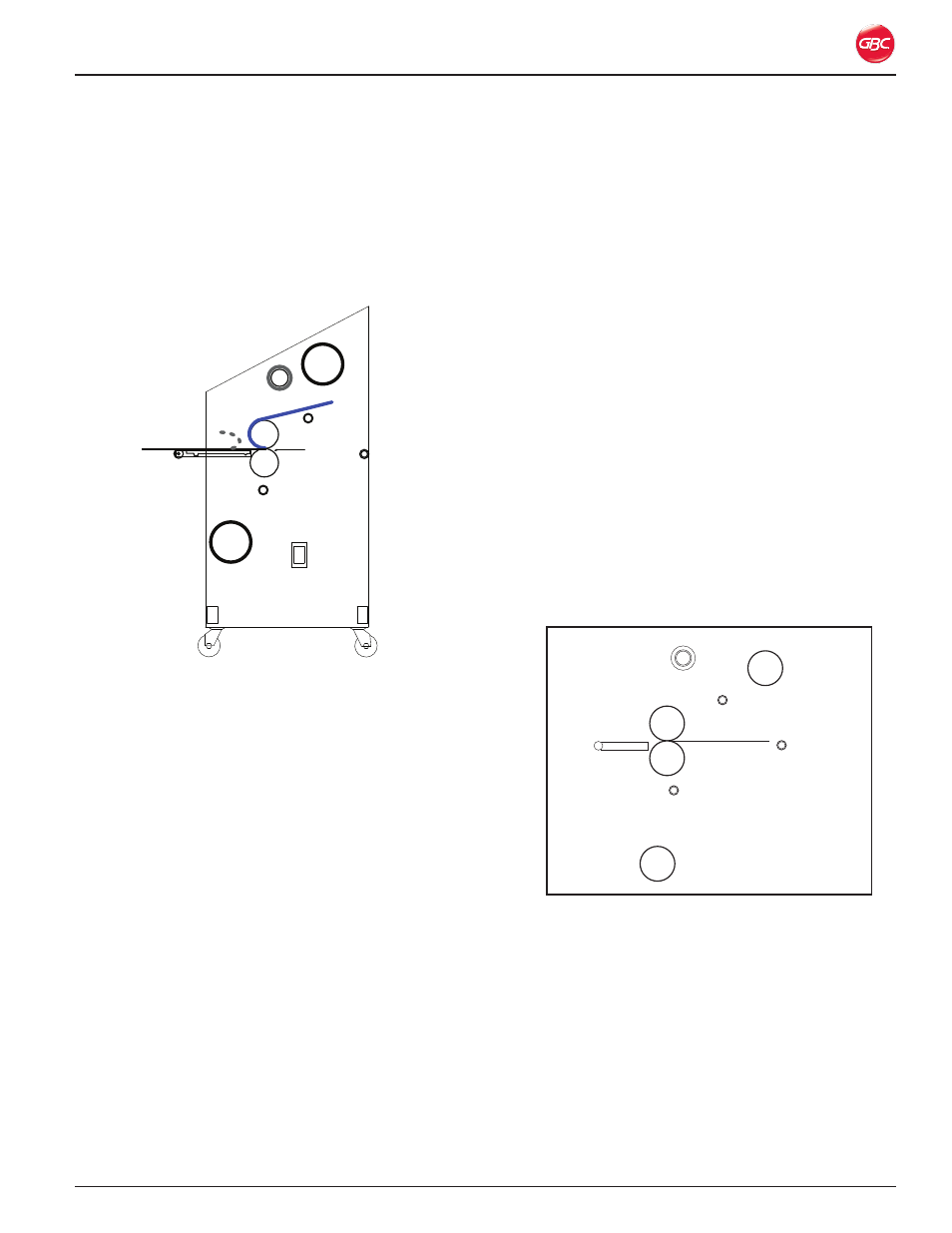

Figure 45. PSA mounting precoat diagram.

To mount a graphic:

1. Set the Main Roller gap to the thickness of the

substrate.

2. Pull 1 to 2 inches (25 to 51 mm) of release liner

off the substrate.

3. Line the graphic up with the edges of the board

and then starting in the middle, tack the leading

edge of the graphic to the substrate.

4. Insert the board into the roller nip, making sure it

is entering the rollers straight.

5. Using the Footswitch, feed the board into the

rollers to the point where the liner separates from

the substrate.

6. Place the graphic over the top of the roller and

through towards the back of the machine.

7. Place one hand on top of the roller to hold the

graphic, and with the other hand, grab the

release liner.

8. Press the Footswitch.

9. As the materials feed into the rollers, pull the

release liner off the substrate.

10. Continue until the graphic and substrate exits the

rollers.

t

Ips

• For larger graphics, a second person at the

back of the laminator can help apply tension

to the graphic. This frees up the person in the

front of the laminator to clean up materials and

handle the release liner.

• If the release liner gets caught in the rollers,

stop the laminator and reverse the materials

out of the rollers until you can pull out the

release liner.

• Do not allow the materials to stop under

the pressure of the rollers for any extended

time. This can cause indentations on softer

substrates.

c

ustom

a

pplIcatIon

n

otes

Use the space below and blank diagrams to

note your tips and web paths for your custom

applications.

t

Ips

For

c

ustom

a

pplIcatIon

#1

Rewinder

Idler

Idler

Idler

Main

Roller

Main

Roller

Supply

Shaft

Supply

Shaft

Figure 46. Custom application 1.

1.

2.

3.

4.