Tips, Pressure sensitive decalling – GBC 64C User Manual

Page 33

Page 6-9

SPIRE II Series – Installation and Operating Instructions

t

Ips

• This process can be performed at any speed.

• Leave small gaps between each substrate as

you feed them into the laminator to make it

easier to separate them.

• The job is easier with two people; one to feed

the substrates and one to separate them as

they exit the laminator.

• AlWAyS RElEASE All TENSION BRAkES,

BOTH UPPER UNWIND AND REWIND,

BEFORE lOADING THE FIlM. ONCE

lOADED, START By ADDING TENSION TO

THE REWIND FIRST.

p

ressure

s

ensItIve

d

ecallInG

Use this process to apply a laminate and a

pressure-sensitive adhesive (PSA) to a graphic at

the same time. This is commonly referred as a decal

and it makes a sticker out of the graphic. After this

process is completed, the graphic can be mounted

to whatever substrate based on the application and

the type of mount adhesive used.

Examples include POP and window signage,

countertop graphics, and refrigeration unit signage.

MR

MR

U

U

R

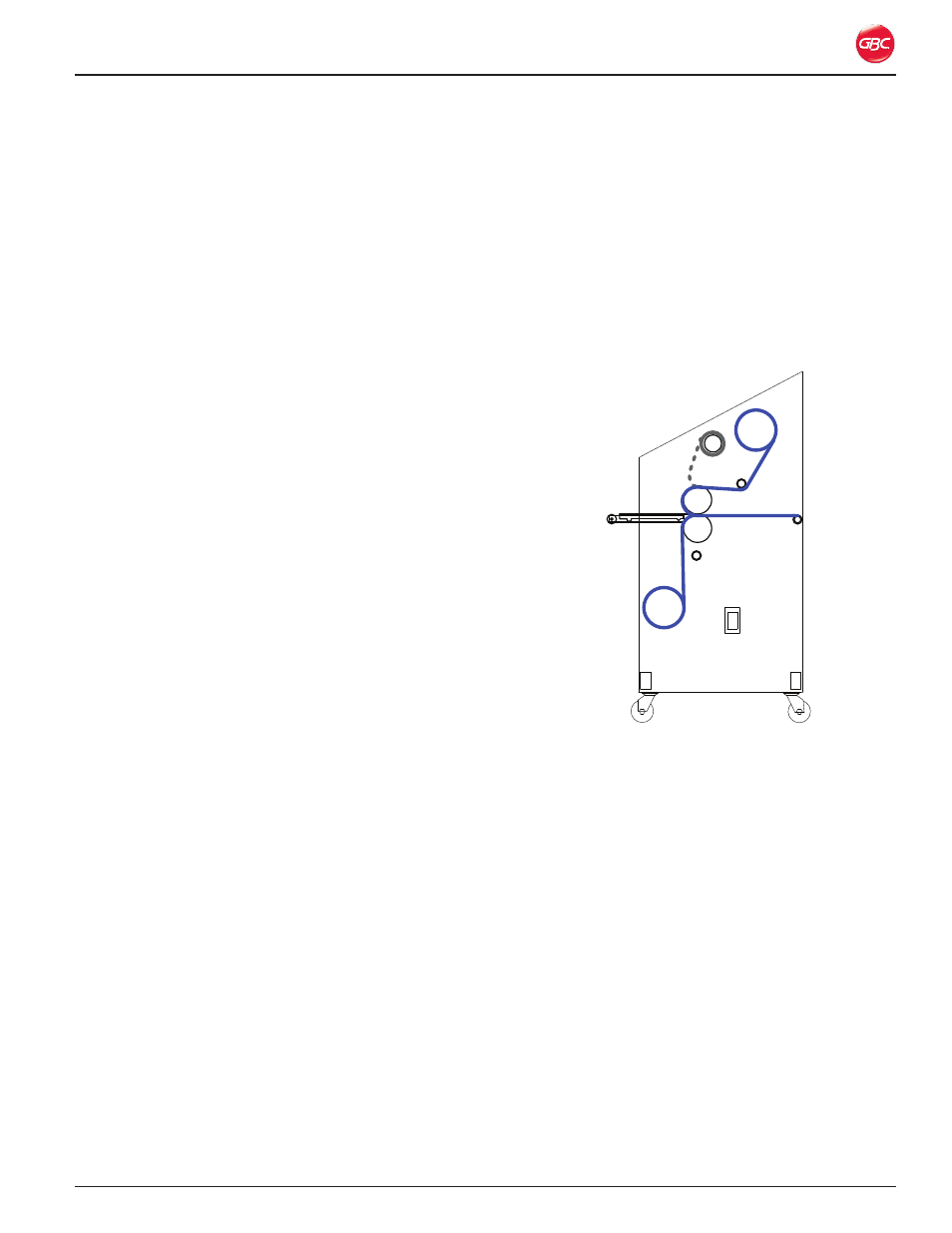

Figure 43. PSA decalling diagram.

To decal a graphic:

1. Load a roll of PSA laminate on the top Unwind

roller.

2. Load a roll of PSA mount on the bottom Unwind

roller.

3. Refer to “Webbing the Machine” for step-by-step

instructions.

t

Ips

• When taping film liner to the Rewind Tube, use

only one piece of tape to allow the film to shift

if necessary and it is easier to remove the liner

later.

• When webbing the top laminate, make sure

the edges of the laminate line up from the

unwind to the laminate roller to ensure the

materials feed straight.