Watts R44-24-1111000 User Manual

Page 25

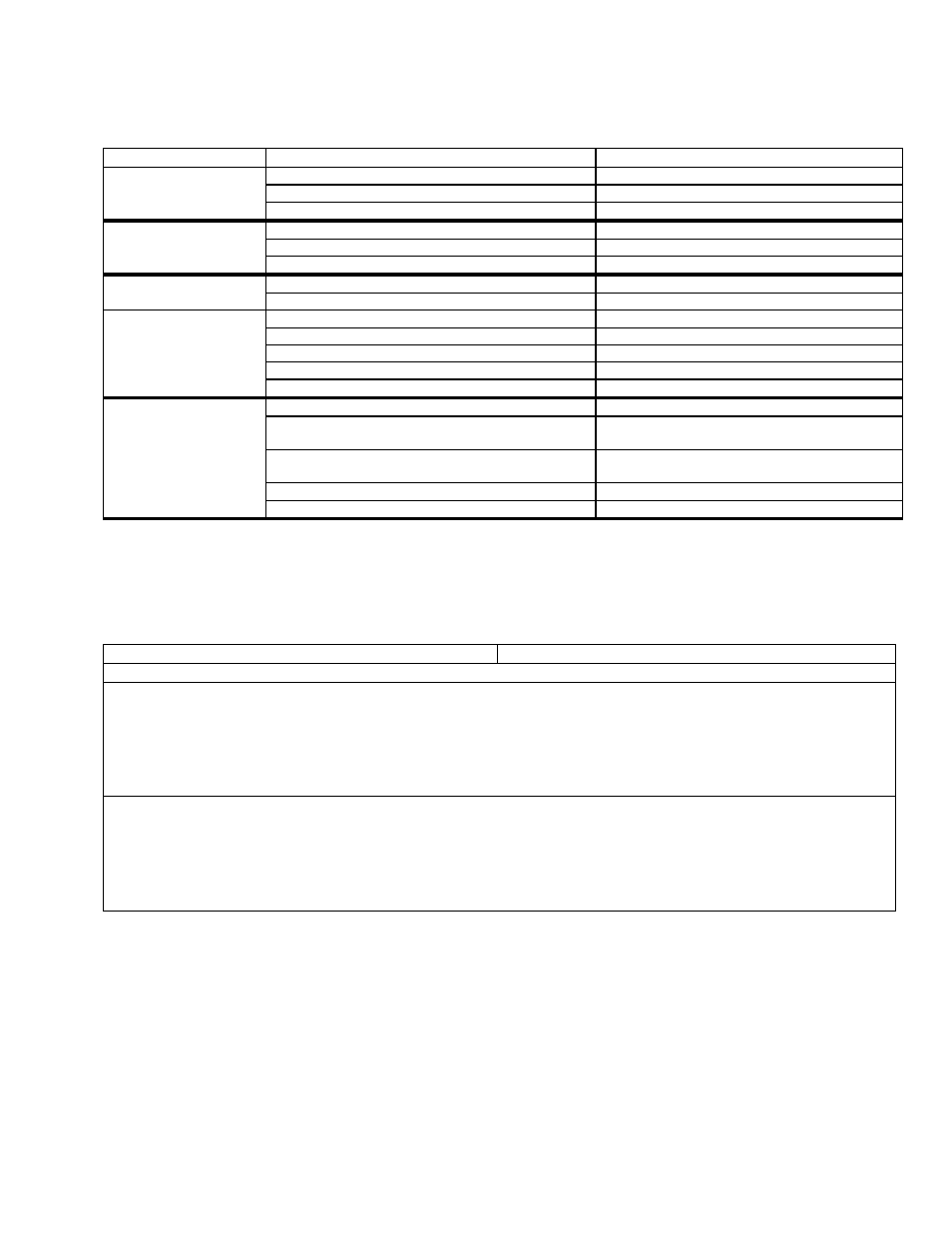

MOTOR TROUBLE SHOOTING CHART (

CONTINUED

)

TROUBLE CAUSE

WHAT

TO

DO

Unbalanced line current

Unequal terminal volts

Check leads and connections

on polyphase motors

Single phase operation

Check for open contacts

during normal operation

Scraping noise

Fan rubbing air shield Remove

interference.

Fan striking insulation

Clear fan.

loose on bedplate

Tighten holding bolts.

Noisy operation

Airgap not uniform

Check and correct bracket fits or bearing.

Rotor

unbalance

Rebalance.

Hot bearings general

Bent or sprung shaft

Straighten or replace shaft.

Excessive belt pull

Decrease belt tension.

Pulleys too far away

Move pulley closer to motor bearing.

Pulley diameter too small

Use larger pulleys.

Misalignment

Correct by realignment of drive.

Hot bearings ball

Insufficient grease

Maintain proper quantity of grease in bearing.

Deterioration of grease, or lubricant contaminated

Remove old grease, wash bearings thoroughly in

kerosene and replace with new grease.

Excess lubricant

Reduce quantity of grease: bearing should not be

more than ½ filled.

Overloaded bearing

Check alignment, side and end thrust.

Broken ball or rough races

Replace bearing: first clean housing thoroughly.

These instructions do not cover all details or variations in equipment nor provide for every possible condition to be

met in connection with installation, operation or maintenance. Chart courtesy of Marathon Electric.

RO SYSTEM TROUBLE SHOOTING

PROBLEM REMEDY

General

High Product Water TDS

Membrane expanded.

Replace membrane.

Membrane attack by chlorine

Carbon pre-filter may be exhausted. Replace with a new cartridge.

Clogged pre-filter-creates pressure drop and low reject flow.

Replace pre-filter cartridge.

Feed pressure too low.

Feed pressure must be at least 20 psi.

Insufficiently flushed post-filter cartridge.

Flush post-filter with pure water.

Brine seal on membrane leaks.

Determine if seal or o-ring is bad. Replace as needed.

No Product Water or Not Enough Product Water

Feed water shut off.

Turn on feed water.

Low feed pressure. Feed pressure must be at least 20 psi.

Consider booster pump.

Pre-filter cartridge clogged.

Replace pre-filter cartridge.

Membrane fouled.

Determine and correct cause; replace membrane.

Product check valve stuck.

Replace check valve fitting.

Low pump discharge pressure

Open pump discharge valve, replace pump