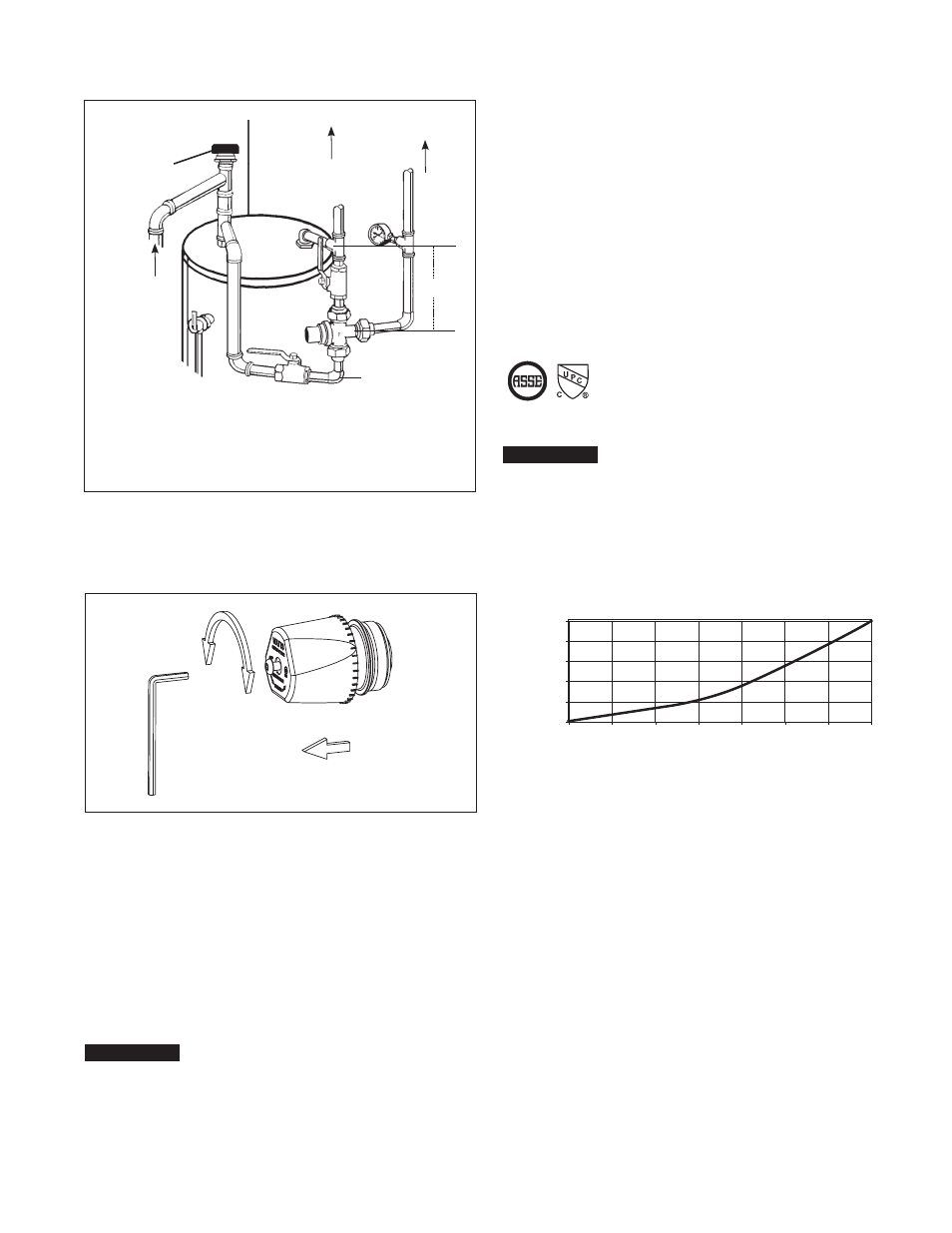

Pressure –– temperature –– flow rate, Capacity, Figure 4 – temperature adjustment – Watts LFMMV User Manual

Page 3: Notice

Pressure –– Temperature –– Flow Rate

Minimum Supply Pressure Static: 30psi (207 kPa)

Inlet Temperatures: hot inlet, 120°F – 180°F (49°C – 82°C),

cold inlet, 39°F – 85°F (4°C – 29°C)

Hot Water Inlet to Outlet Differential Temperature: 5°F (3°C)

Temperature Out: Field range: 80°F – 120°F (27°C – 49°C),

adjustable; Accurate within ±3°F (1.7°C)

†

Maximum Temperature: 200°F (93°C)

Maximum Pressure: 150psi (1034 kPa)

Minimum Flow: 0.5 gpm (1.9 lpm) @.08psi (0.55 kPa)

†

Maximum Flow: 20 gpm (76 lpm) @ 125psi (862 kPa)

†

Maximum Pressure Differential between

Hot & Cold Water Supplies: 25% maximum differential

Listing: ASSE 1017, ASSE 1069, ASSE 1070 and IAPMO cUPC

†

When tested in accordance with ASSE 1017, ASSE 1069, ASSE 1070

and IAPMO cUPC.

NOTICE

To prolong the life of the series LFMMV when used in an

ASSE 1017 application, it is recommended that it be trapped as

shown; i.e. the hot water inlet to the LFMMV should be 8"-12"

(200-305mm) below the hot water supply feed.

Flow curves are for reference. Actual flows may vary depending

on system temperatures and/or pressures.

*Flow curve with integral inlet filters and check valves

Capacity*

kpa psi

345 50

276 40

207 30

138 20

69 10

0

0

2

4

6

8

10

12

14

gpm

7.6

15

23

30

38

46

53

lpm

Pressure Drop

† Devices tested to ASSE 1069 or ASSE 1070 such as Watts

Series LFUSG or LFMMV should be used at fixture to

prevent possible injury.

Watts

Vacuum Relief

Valve

Watts Temperature

Gauge

Cold

Cold

Cold

LFMMV-M1

Tempered

†

Hot

Hot to

Appliances

Watts T&P

Relief Valve

*8" – 12"

H

C

M

Figure 3 – Typical ASSE 1017 Application

Hotter

3

/

32

" Hex Wrench

Turn

Colder

Unscrew, lift

cap to adjust

Figure 4 – Temperature Adjustment

1. Let the water flow for at least two minutes to allow supply

temperature to stabilize.

2. Calibrate the mixed water outlet temperature by placing a

thermometer in the mixed water stream.

3. To adjust the setting of the valve, loosen locking cap screw

with hex wrench, see Figure 4. Cap must be lifted

1

/

4

" to

adjust temperature. To increase the temperature, turn coun-

terclockwise. To decrease temperature turn clockwise.

4. Lower handle and tighten screw.

5. Check outlet temperature.

NOTICE

It is recommended that shutoff valve(s) be installed on the inlet(s)

to facilitate service of the LFMMV-M1 valve.