Watts LF3004 User Manual

Series lf3004, Lead free, Dielectric unions

For Residential and Commercial Applications

ES-LF3004

LF3004

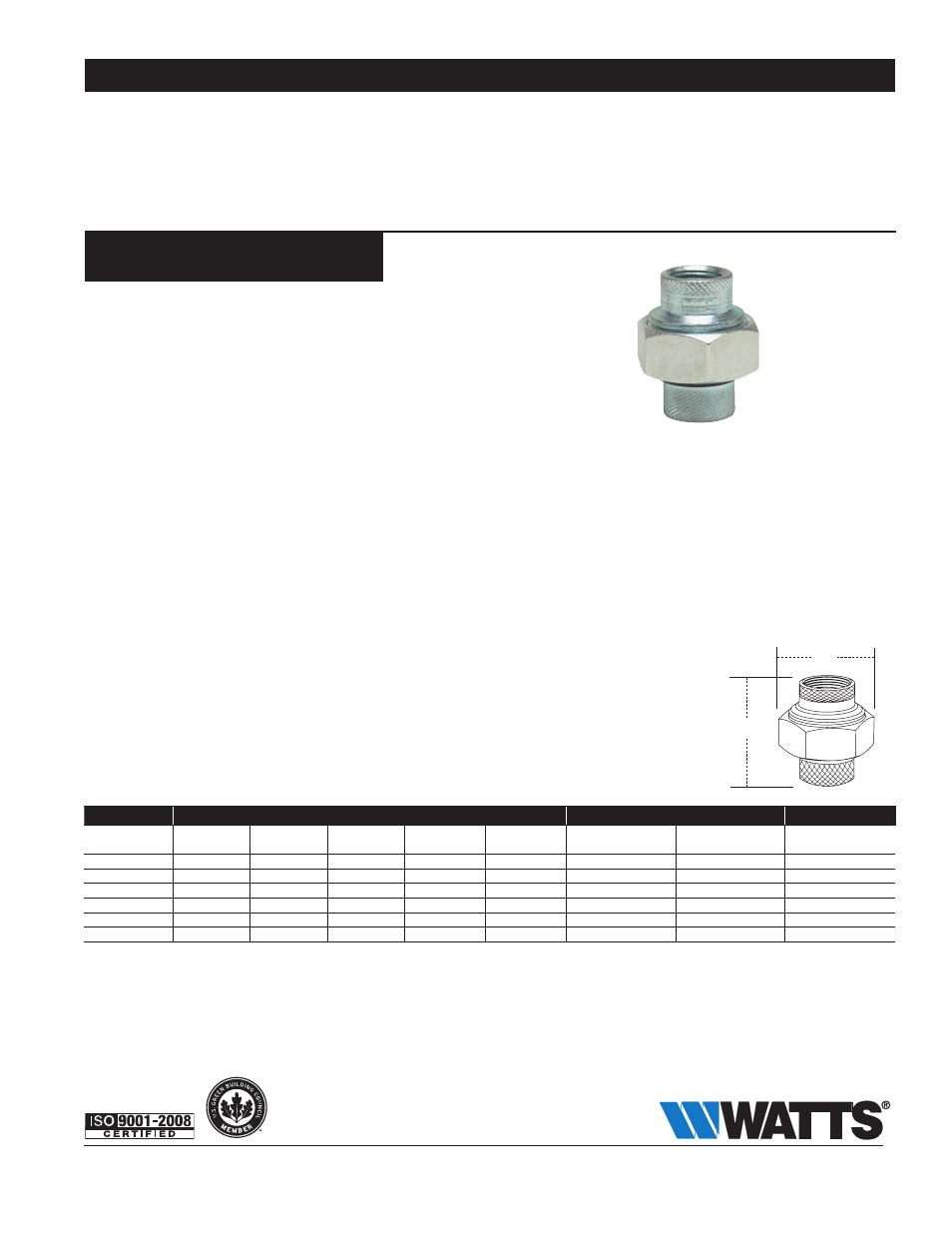

Series LF3004

Dielectric Unions

Sizes:

1

⁄

2

" – 2" (15 – 50mm)

Series LF3004 Dielectric Unions feature female iron pipe thread

to female iron pipe thread (zinc plated) connections. These

unions are designed to be installed to prevent accelerated cor-

rosion and deterioration in the piping system due to galvanic

and stray current. The LF3004 features Lead Free* construction

to comply with Lead Free* installation requirements.

Features

• Female iron pipe thread to female iron pipe thread

(zinc plated) connections.

• Designed and manufactured to the highest quality standards

• Individually factory certified to withstand a minimum of 600

volts on a dry line with no flashover

• Rated to 180°F (82°C) at 250psi (17.2 bar)

Specifications

A dielectric union shall be installed where indicated on the

plans. The union shall feature a female iron pipe thread to

female iron pipe thread (zinc plated) connections. The union

shall be a Watts Series LF3004.

Materials — Dimensions — Weights

B

A

Standards

Meets federal specifications for tensile strength and thread end

connections

Pressure — Temperature

Maximum Pressure: 250psi (17.2 bar)

Maximum Temperature: 180°F (82°C)

ES-LF3004 1325

© 2013 Watts

USA: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.watts.ca

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements, please contact Watts Technical Service. Watts

reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications

on Watts products previously or subsequently sold.

A Watts Water Technologies Company

*The wetted surface of this product contacted by consumable water

contains less than 0.25% of lead by weight.

LEAD FREE

*

Job Name –––––––––––––––––––––––––––––––––––––––––––

Contractor ––––––––––––––––––––––––––––––––––––––––––––

Job Location –––––––––––––––––––––––––––––––––––––––––

Approval –––––––––––––––––––––––––––––––––––––––––––––

Engineer –––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No. ––––––––––––––––––––––––––––––––––

Approval –––––––––––––––––––––––––––––––––––––––––––––

Representative ––––––––––––––––––––––––––––––––––––––––

Size

MATeRiALS

DiMeNSiONS

WeiGHT

TAIL PIECE †

ADAPTER †

NUT †

INSULATOR

GASKET

A

B

in.

mm

in.

mm

in.

mm

oz.

gm.

1

⁄

2

15

Steel

Steel

Steel

Polysulfone

Buna-N

1

5

⁄

8

41

2

1

⁄

4

57

7.8

221

3

⁄

4

20

Steel

Steel

Steel

Polysulfone

Buna-N

1

7

⁄

8

48

2

1

⁄

4

57

10.9

309

1

25

Steel

Steel

Steel

Polysulfone

Buna-N

2

1

⁄

4

58

2

1

⁄

2

64

16.6

471

1

1

⁄

4

32

Steel

Steel

Malleable Iron

Polysulfone

Buna-N

2

3

⁄

4

70

2

3

⁄

4

70

23.5

666

1

1

⁄

2

40

Malleable Iron

Malleable Iron

Malleable Iron

Polysulfone

Buna-N

3

1

⁄

2

89

2

3

⁄

4

70

44.5

1262

2

50

Malleable Iron

Malleable Iron

Malleable Iron

Polysulfone

Buna-N

4

1

⁄

8

105

3

1

⁄

8

79

67.2

1905

† Steel and malleable iron components are zinc plated