1116fm (angle) - pressure relief valve, Maintenance, Disassembly/assembly – Watts 1116FM User Manual

Page 3

Valve Size

150 Outlet

300 Outlet

150 Inlet

300 Inlet

150 Inlet

300 Inlet

A

A

B

B

C

D

D

E

F

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

3

80

5

3

⁄

4

146

6

1

⁄

8

156

5

3

⁄

4

146

6

1

⁄

8

156

5

1

⁄

2

140

17

1

⁄

2

445

17

3

⁄

4

451

9

1

⁄

2

241

7

7

⁄

8

200

4

100

6

3

⁄

4

171

7

1

⁄

8

181

6

3

⁄

4

171

7

1

⁄

8

181

5

1

⁄

2

140

19

1

⁄

4

489

19

5

⁄

8

498

10

254

9

15

⁄

16

252

6

150

8

1

⁄

2

216

8

15

⁄

16

227

8

1

⁄

2

216

8

15

⁄

16

227

4

102

24

1

⁄

2

622

25

635

11

279

13

1

⁄

4

337

8

800

11

279

11

1

⁄

2

292

11

279

11

1

⁄

2

292

4

102

26

3

⁄

4

679

27

1

⁄

4

692

13

330

16

406

USA: • Tel. (713) 943-0688 • (713) 944-9445 • www.watts.com

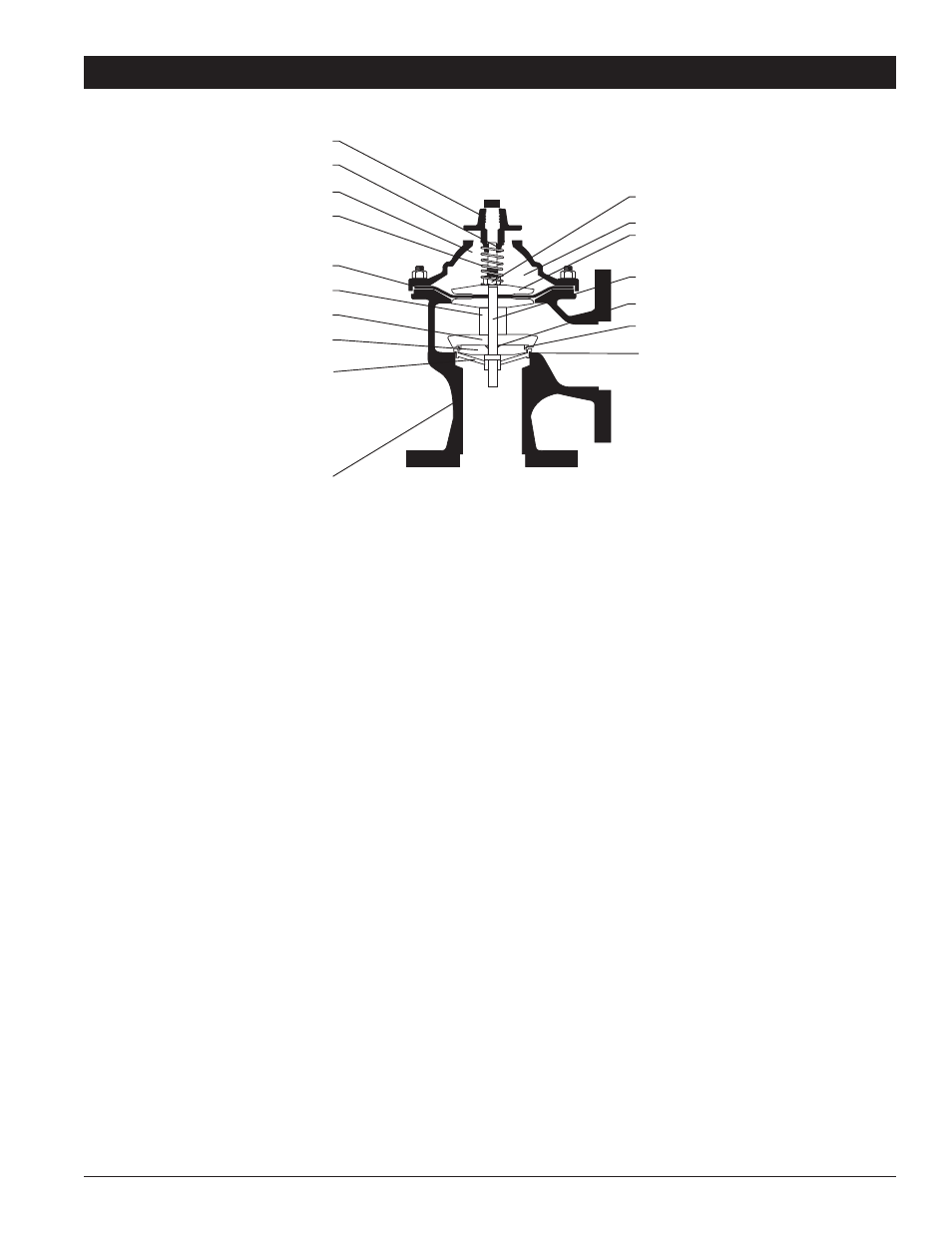

1116FM (Angle) - Pressure Relief Valve

Cover

Cover bearing

Cover chamber

Spring

Diaphragm

Stem

Spacer

Retainer

Quad seal

retainer plate

Quad seal

Seat

Seat O-ring

Body

Stem O-ring

Diaphragm

Washer

Stem nut

Maintenance

The basic valve normally requires a minimum of maintenance, due

to a packless construction and no required lubrication. However,

it is suggested that a periodic inspection schedule be established

to determine how the fluid is affecting the efficiency of the valve.

Fluid velocity as well as any substance entrained in the fluid, such

as dissolved minerals and/or suspended particles, vary between

installations. In areas subject to freezing, remove the body cover

drain plugs for winter drain-down.

NOTICE: The following method will determine if there is a dam-

aged diaphragm without removing the valve cover. Put pres-

sure into the valve and close all control lines to the valve cover

chamber.Remove a fitting on the valve cover. If there is a con-

tinuous flow out of the cover chamber through this opening, the

diaphragm is damaged or the diaphragm assembly on the stem

is loose.

CAUTION: The valve will be wide open during this pro-

cedure.Omit if the fully open valve could result in system damage.

Disassembly/Assembly

Inspection or maintenance can be accomplished without removal

from the line.

To replace the diaphragm and/or the quad ring:

1. Remove fitting nuts where necessary to release the valve

cover from the controls or control lines.

2. Remove the cover and spring.

3. Remove the diaphragm and stem assembly, taking care not

to damage the diaphragm when removing over studs.

4. With the assembly removed, examine the diaphragm and

quad ring for wear or damage. Do not disassemble unless

replacement is indicated.

5. To replace the diaphragm, quad ring and/or stem O-ring,

hold the stem in a vise or with wrench on the flats at the

bottom end of the stem. Remove the nuts.

6. Remove the diaphragm washer, diaphragm, etc., in the

proper sequence.

7. Check all surfaces, seat, O-ring grooves and diaphragm

clamping surfaces for damage and/or foreign particles.

8. To reassemble, reverse the order of disassembly. Tighten

stem nuts securely to ensure proper clamping of the dia-

phragm. To assure positive and even clamping of the dia-

phragm between the body and the cover, gradually tighten

the cover nuts diametrically opposite each other.