1116fm (angle) - pressure relief valve, Dimensions - acv 1116fm (angle), Installation and start-up – Watts 1116FM User Manual

Page 2: 125 by: checked by: revision: supercedes, Bd e a

300

0

60

30

240

270

90

120 150

210

180

INLET

150 LB FLANGE

OUTLET

150 LB FLANGE

Ш7.875"

Ш9.968"

Ш13.25"

Ш16.00"

150 LB FLANGE

INLET

5 3/4"

6 3/4"

8 1/2"

INLET

17 1/2"

26 3/4"

24 1/2"

19 1/4"

8 200

6 150

4 100

3 80

17 3/4"

19 5/8"

27 1/4"

25"

11"

150 LB FLANGE

INLET

INCH - MM

VALVE SIZE

A

300 LB FLANGE

A

B

INLET

INLET

5 3/4"

6 3/4"

8 1/2"

6 1/8"

7 1/8"

11 1/2"

8 15/16"

11"

11 1/2"

8 15/16"

7 1/8"

6 1/8"

150 LB FLANGE

300 LB FLANGE

B

C

INLET

300 LB FLANGE

C

D

5 1/4"

5 1/2"

4"

13"

9 1/2"

9 1/2"

11"

4"

E

F

TOP

VIEW

6 INCH ANGLE

150 LB BY 150 LB

XXXX

WA

TTS

XX

X

AC

V

TITLE:

DRAWING NUMBER:

NAME:

DATE:

DESIGN BY:

DRAWN BY:

CHECKED BY:

APPROVED BY:

REVISIONS:

DATE:

TOLERANCES:

EXCEPT

AS

NOTED

FRACTIONAL

ANGULAR

DECIMAL

.XX DIMS

.XXX DIMS

.XXXX DIMS

SCALE

SURFACE

EXCEPT

AS

NOTED

+

+

+

+

+

1/64

1/2°

.01

.005

.001

125

BY:

CHECKED BY:

REVISION:

SUPERCEDES:

CONTROL

VALVE

AUTOMATIC

HOUSTON, TEXAS

WATTS AUTOMATIC CONTROL VALVE COMPANY

B

D

E

A

Ш13.25"

Ш9.968"

Ш13.25"

Ш16.00"

8 1/2"

6 3/4"

8 1/2"

26 3/4"

24 1/2"

24 1/2"

19 1/4"

8 800

8 200

6 150

4 100

25"

19 5/8"

27 1/4"

25"

11"

6 3/4"

8 1/2"

8 1/2"

7 1/8"

11 1/2"

8 15/16"

8 15/16"

11"

11 1/2"

8 15/16"

8 15/16"

7 1/8"

5 1/2"

13"

4"

9 1/2"

11"

11"

4"

4"

F

C

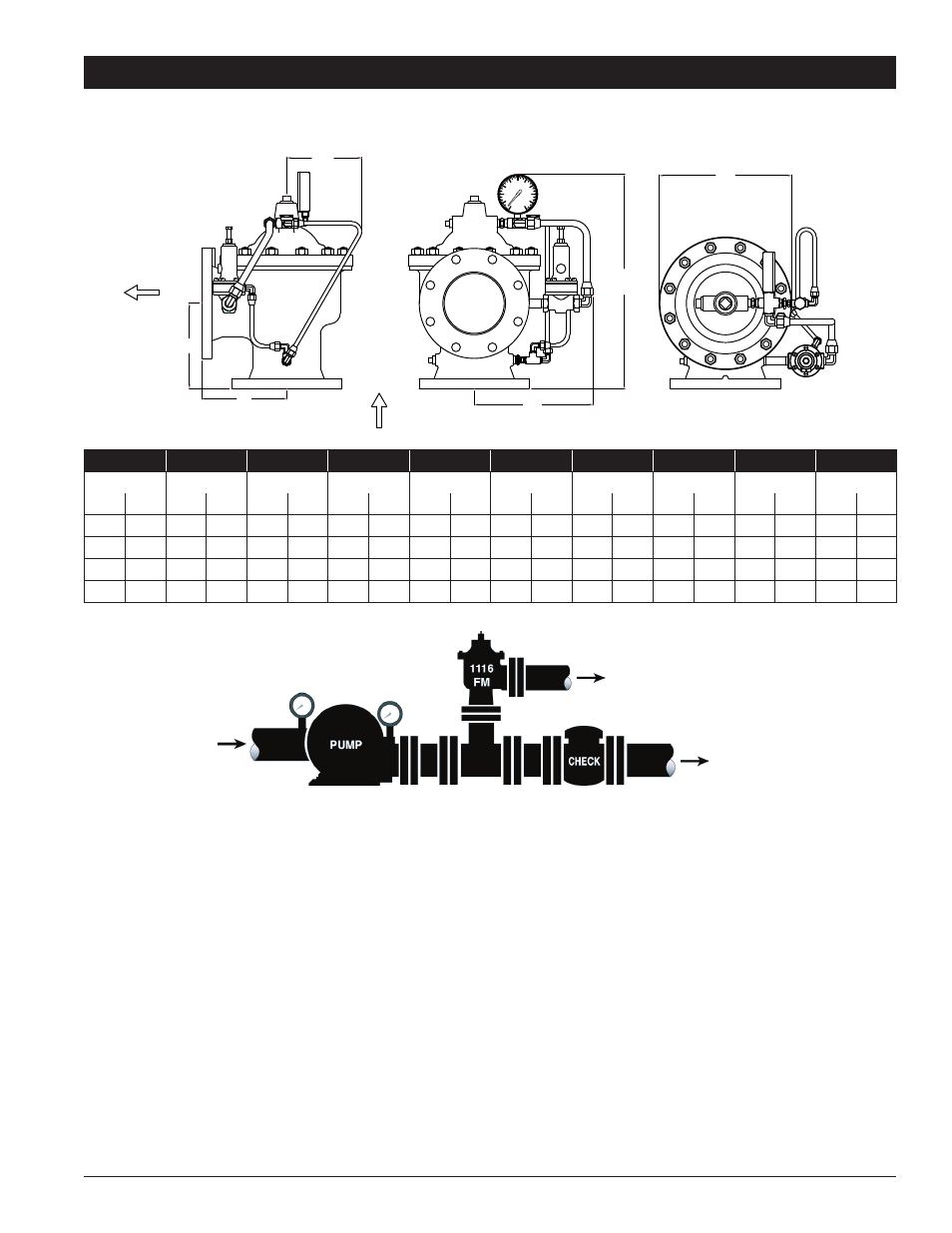

DIMENSIONS - ACV 1116FM (Angle)

TO FIRE

PROTECTION

SYTEM

TO WASTE CONE

SUPPLY

FIRE PUMP RELIEF VALVE

Valve Size

150 Outlet

300 Outlet

150 Inlet

300 Inlet

150 Inlet

300 Inlet

A

A

B

B

C

D

D

E

F

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

3

80

5

3

⁄

4

146

6

1

⁄

8

156

5

3

⁄

4

146

6

1

⁄

8

156

5

1

⁄

2

140

17

1

⁄

2

445

17

3

⁄

4

451

9

1

⁄

2

241

7

7

⁄

8

200

4

100

6

3

⁄

4

171

7

1

⁄

8

181

6

3

⁄

4

171

7

1

⁄

8

181

5

1

⁄

2

140

19

1

⁄

4

489

19

5

⁄

8

498

10

254

9

15

⁄

16

252

6

150

8

1

⁄

2

216

8

15

⁄

16

227

8

1

⁄

2

216

8

15

⁄

16

227

4

102

24

1

⁄

2

622

25

635

11

279

13

1

⁄

4

337

8

800

11

279

11

1

⁄

2

292

11

279

11

1

⁄

2

292

4

102

26

3

⁄

4

679

27

1

⁄

4

692

13

330

16

406

USA: • Tel. (713) 943-0688 • (713) 944-9445 • www.watts.com

1116FM (Angle) - Pressure Relief Valve

Installation and Start-up

Start-up of an Automatic Control Valve requires following proper procedures. Time must be allowed for the valve to react

to adjustments and the system to stabilize. The objective is to bring the valve into service in a controlled manner to protect

the system from damaging overpressure.

NOTICE: Avoid mounting valves in a vertical discharge postion (valve stem horizontal or cover pointed sideways.) Valves mounted in

this position may not perform as tested and approved.

•

Clear the line of slag and other debris.

•

Install the valve so that the FLOW ARROW marked on the valve body matches the flow through the line.

•

Install pressure gauge (supplied) in the fitting on valve tubing.

1. Turn the Relief Control adjustment screw counterclockwise (out). This lowers the initial relief set-point, allowing the set-point to be

increased to the desired setting.

2. Loosen a tube fitting at a high point on the valve. This allows the cover to vent trapped air during initial filling of the valve.

3. Start the pump to supply fluid/pressure to the valve.

4. Tighten the tubing when all air is vented from the cover as indicated by continual flow of fluid.

NOTICE: THE RELIEF SET-POINT SHOULD BE LOWER THAN DESIRED AT THIS TIME.

5. Turn the Relief Control adjustment screw clockwise (in) slowly, allowing time for the pressure to gradually increase to the desired

set-point.