Notice – Watts LF909 User Manual

Page 3

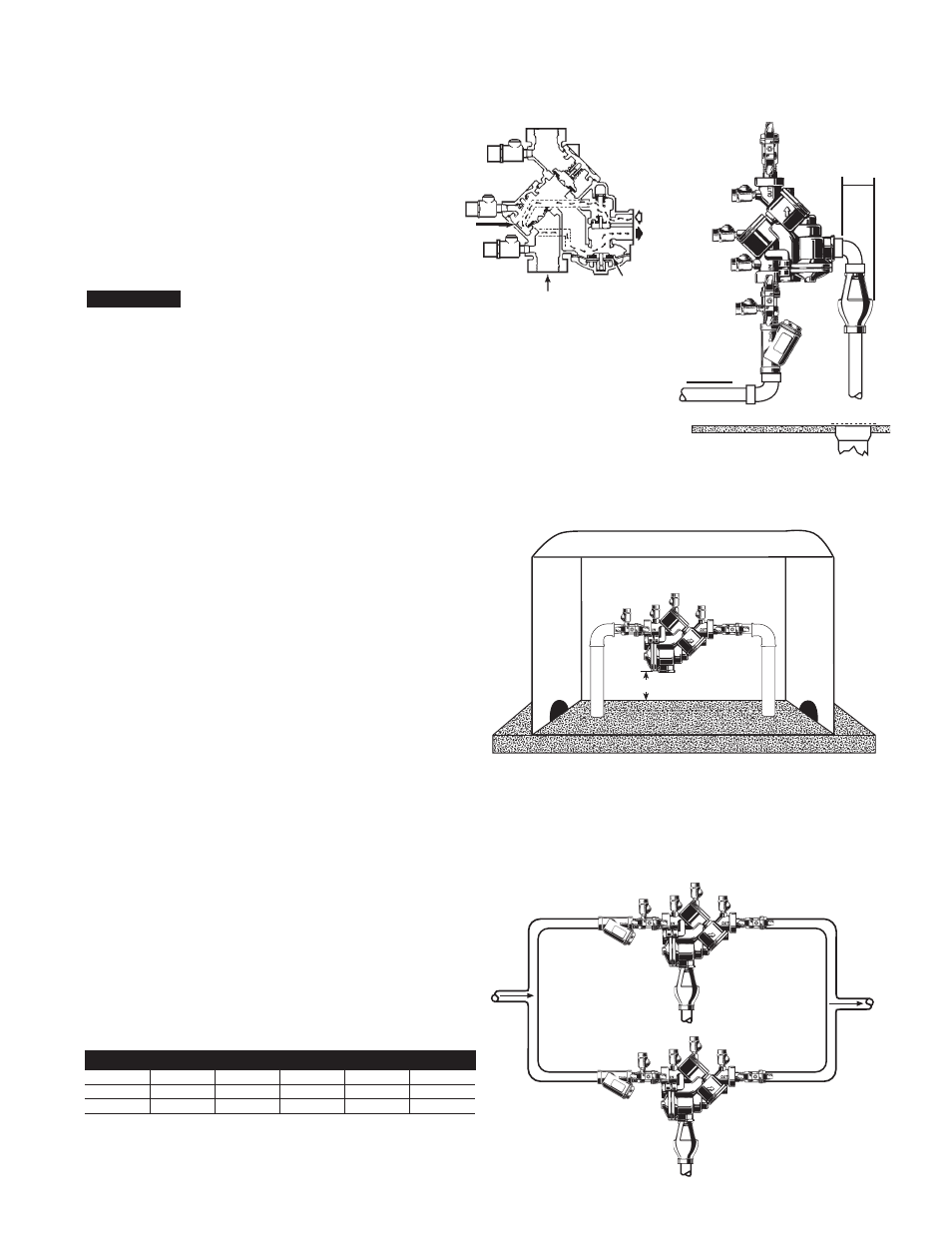

Now available, WattsBox Insulated Enclosures,

for more information, send for ES-WB or ES-WB-T.

FIBERGLASS WattsBox

Min. 12"

ASSE approved for vertical installation

3

⁄

4

" – 2" flow up and down

3

For indoor installations, it is important that the valve be

easily accessible to facilitate testing and servicing. Series

909 and LF909 may be installed either vertically or hori-

zontally. If it is located in a line close to wall, be sure the

test cocks are easily accessible. A drain line and air gap

should be piped from the relief valve connection as shown,

where evidence of discharge will be clearly visible and so

that water damage will not occur. Therefore, never install

in concealed locations.

NOTICE

Test cock must be located on the first or inlet shutoff

valve.

Flow

Relief Valve

Below First Check

Valve

Air In

Water

Out

Main

▼

Min.

4

1

⁄

2

"

▼

▼

Air*

Gap

First

Check

Valve

909QT-S/

LF909QT-S

Vertical Installation - Upward Flow

*For Air Gap information contact your technical

sales representative or refer to ES-AG/EL/TC.

In an area where freezing conditions do not occur, Series 909/LF909

can be installed outside of a building. The most satisfactory installa-

tion is above ground and should be installed in this manner when-

ever possible.

In an area where freezing conditions can occur, Series 909/LF909

should be installed above ground in an insulated enclosure.

Series 909/LF909 may be installed in a vertical or horizontal line

and in an accessible location to facilitate testing and servicing. A

discharge line should be piped from the air gap at the relief valve

connection making sure there is adequate drainage. Never pipe the

discharge line directly into a drainage ditch, sewer or sump. Series

909 and Series LF909 should never be installed where any part of

the unit could become submerged in standing water. Consideration

should be given to the installation of external support structure as

applicable.

It is generally recommended that backflow preventers never be

placed in pits unless absolutely necessary, and then only, when

approved by local codes. In such cases, a modified pit installation is

preferred.

Two or more smaller size valves can be piped in parallel (when

approved) to serve a larger supply pipe main. This type of installation

is employed where increased capacity is needed beyond that provid-

ed by a single valve and permits testing or servicing of an individual

valve without shutting down the complete line.

The number of valves used in parallel should be determined by the

engineer’s judgement based on the operating conditions of a specific

installation.

Installation Indoors

Installation - Outside Building Above Ground

Installation - Parallel Consult Local Codes for Approval

909QT-S/LF909S

909QT-S/LF909QT-S

Air Gap

(Drawings not to scale)

TABLE OnE - CAPACITy REQuIRED FOR SySTEM

50 gpm

100 gpm

150 gpm

200 gpm

250 gpm

350 gpm

Two

3

⁄

4

"

Two 1"

Two 1

1

⁄

4

"

Two 1

1

⁄

2

"

Two 1

1

⁄

2

"

Two 2"

Devices

Devices

Devices

Devices

Devices

Devices

Table shows total capacity provided with dual valve installations of various sizes.