How it operates, Basic installation instructions watts – Watts LF909 User Manual

Page 2

1. Backflow preventers must be installed in high-visibility locations

in order to allow for immediate notice of telltale discharge or

other malfunction. This location should also facilitate testing and

servicing, and protect against freezing and vandalism.

2. Installing a backflow preventer in a pit or vault is not recom-

mended as flooding of the pit will cause a crossconnection.

Ensure that

all local codes and required safety provisions

are met. An air gap below the relief port must be maintained so

as to avoid, flooding and submersion of the assembly, which

may lead to a cross-connection.

3. A strainer should be installed ahead of the backflow preventer to

protect all internal components from unnecessary fouling.

CAUTION

!

Do not install a strainer ahead of the backflow preventer on seldom-

used, emergency water lines (i.e. fire sprinkler lines). The strainer

mesh could potentially become clogged with debris present in the

water and cause water blockage during an emergency.

4. Normal discharge and nuisance spitting are accommodated by

the use of a Watts air gap fitting and a fabricated indirect waste

line. Floor drains of the same size

MUST be provided in case of

excessive discharge.

5. When a 909 and LF909 Series backflow preventer is installed for

dead-end service applications (i.e. boiler feed lines, cooling

tower makeup or other equipment with periodic flow require-

ments), discharge from the relief vent may occur due to water

supply pressure fluctuation during static no-flow conditions. A

check valve may be required ahead of the backflow preventer.

*Please see “Troubleshooting”, page 7,

prior to installation.

6. The 909 and LF909 Series backflow preventer is designed so

that the critical level of the relief valve is positioned below the

first check. This unique feature allows the valve to be

installed

either vertically or horizontally.

7.

Installation procedures must comply with all state and

local codes. *Please see page 3 for specific installation proce-

dures.

8. Prior to installation, thoroughly flush all pipe lines to remove any

foreign matter.

9.

Start up at Initial Installations and After Servicing: The down-

stream shutoff should be closed. Slowly open upstream shutoff

and allow the backflow preventer to fill slowly. Bleed air at each

test cock. When backflow preventer is filled, slowly open the

downstream shutoff and fill the water supply system. This is nec-

essary to avoid dislodging O-rings or causing damage to internal

components.

10.

Test: The 909 and LF909 Series backflow preventer must be

tested by a certified tester at the time of installation in order to

ascertain that the assembly is in full working order and may be

relied upon to protect the safe drinking water as per applicable

standards.

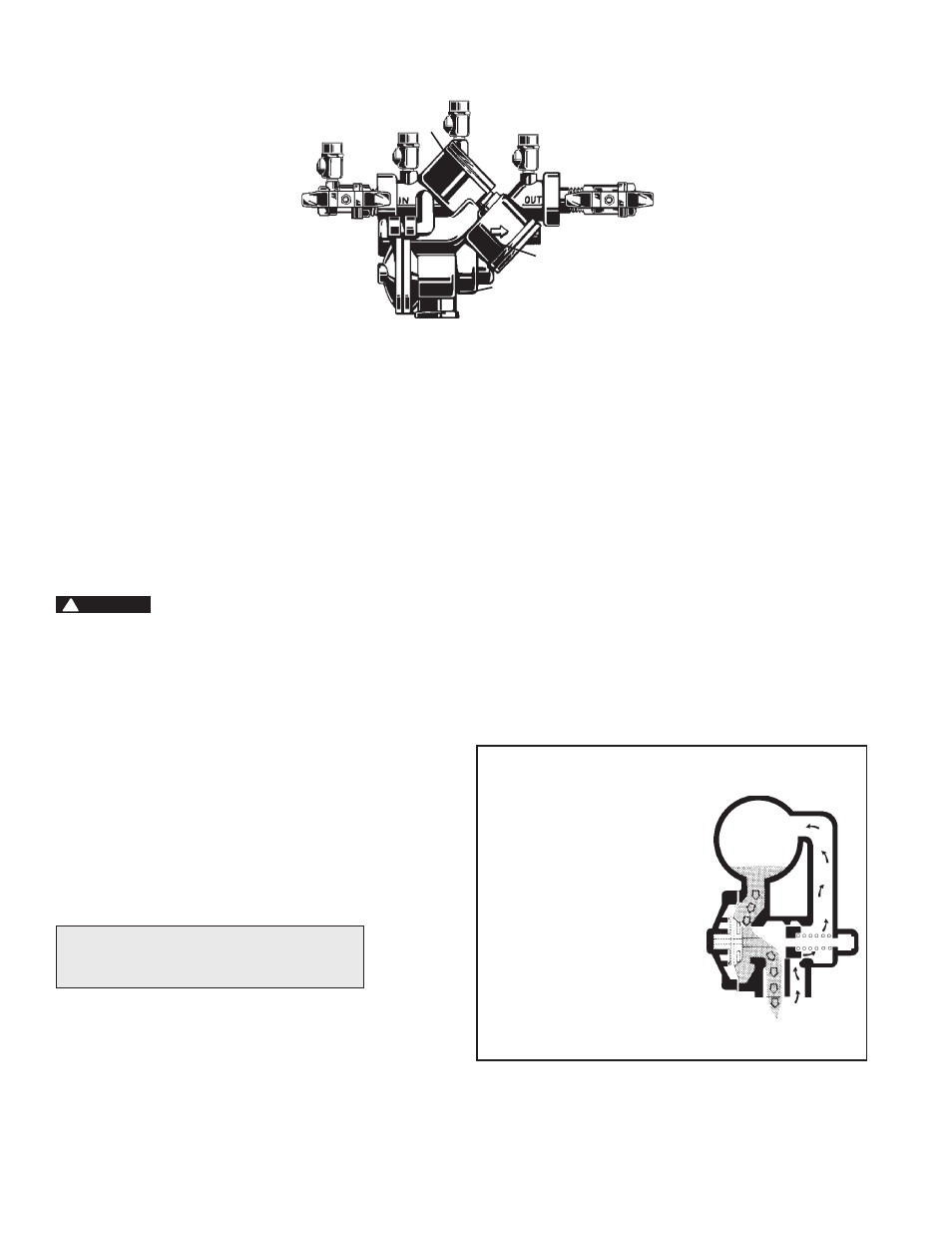

First

Check

Relief

Valve

Second

Check

909QT/LF909QT

How It Operates

The unique relief valve

construction incorporates two

channels: one for air, one for

water. When the relief valve

opens, as in the accompanying

air-in/water-out diagram, the

right hand channel admits air to

the top of the reduced pressure

zone, relieving the zone vacuum.

The channel on the left then

drains the zone to atmosphere.

Therefore, if both check valves

foul, and simultaneous negative

supply and positive backpressure

develops, the relief valve uses the

air-in/water-out principle to stop

potential backflow.

Reduced

Pressure

Zone

Water Out

Air In

2

Basic Installation Instructions

Watts

3

⁄

4

" – 2" (20-50mm) 909QT/LF909QT High Capacity Relief Series:

Location and Installation Considerations

For repair kits and parts, refer to our Backflow

Prevention Products Repair Kits & Service Parts

price list PL-RP-BPD found on

www.watts.com.