C. electrical, Pwro440 deluxe controller d. startup, E. control function – Watts PWRO440 User Manual

Page 4

4

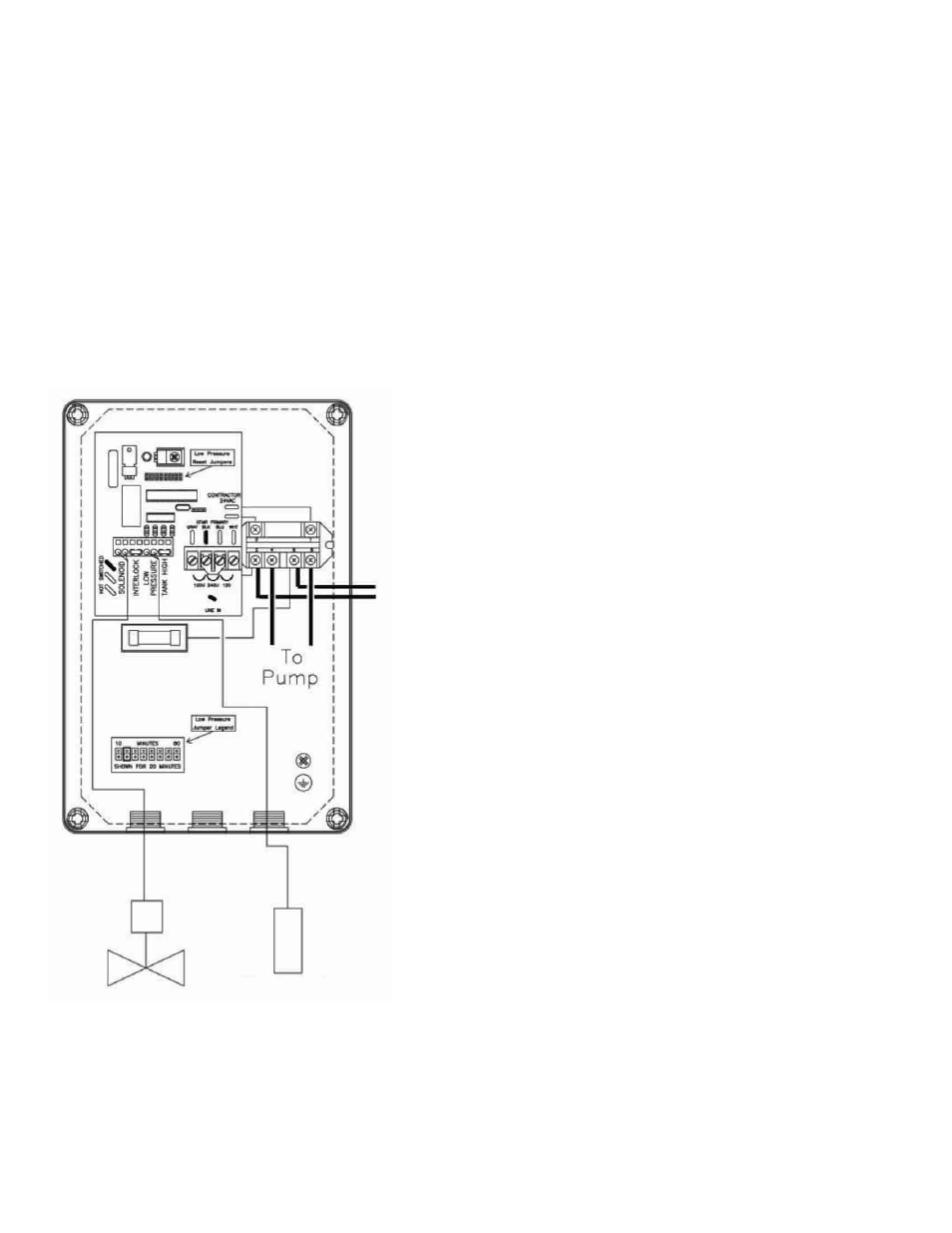

C. Electrical

Note: It is the responsibility of the end user to ensure that the

installation is done according to local codes and regulations.

1. Make sure the on / off switch is in the off position (Figure # 1

item A).

2. Wire the common side of the motor starter to the incoming

power.

3. Connect the incoming power supply to the contactor terminals

as shown.

4. Optional - remove the jumpers and connect the high tank level

switch and / or the pretreatment lock out switch to the control-

ler terminal strip. These should be normally closed dry contacts

only (do not apply power to these terminals). When the circuit

between the two terminals is complete, the RO will run. When

the circuit is open the RO will shut down and the light on the

front of the controller will turn on.

PWRO440 Deluxe Controller

D. Startup

1. Verify that the pretreatment equipment is installed and working

properly. Verify that no free chlorine is present in the feed water.

2. Verify that the on / off switch is in the off position.

3. Verify that a filter cartridge is installed in the prefilter housing.

4. Open the reject control valve completely (Figure # 1 item D) by

turning it counterclockwise.

5. Close the reject recycle control valve (Figure # 1 item E) com-

pletely by turning it clockwise.

6. Open the feed water shutoff valve installed in step III-B-1 above.

7. Move the controller on/off switch to the on position.

8. Allow the unit to run for 15 – 30 minutes to flush the preservative

from the membrane(s).

9. Adjust the reject control valves (Figure # 1 items D & E) until the

desired flows are achieved. Closing the reject valve increases

the product flow and decreases the reject flow. Opening the

reject recycle valve decreases both the reject and product flow.

See the flow rate guidelines and temperature correction table in

the appendix to determine the flow rates for different operating

temperatures.

10. Allow the product water to flow to drain for 30 minutes.

11. Turn off the system and connect the product water line to the

point of use. The product water line should never be restricted.

Membrane and/or system damage may occur if the product

water line is blocked.

12. Restart the system and record the initial operating data using the

log sheet.

E. Control Function

1. When the power switch is turned on, the pump will run as long

as the circuit between the tank level terminals and the interlock

terminals are closed. The RO pump and inlet valve will turn on

when the level switch contacts are closed (tank not full). The RO

pump and inlet valve will turn off if the level switch contacts open

(tank full) or the pretreatment interlock contacts open.

2. If the pump suction pressure drops below the pressure switch

set point (3 – 5psi) for five (5) seconds, the RO pump and inlet

valve will turn off. A red light on the front of the controller will turn

on to indicate that the unit has shutdown due to low pressure.

Turn the controller off and back on to reset the unit. The control-

ler will automatically reset after 30 minutes. The reset time can

be adjusted by moving the jumper cap inside the controller.

3. Quality Meter – The quality meter measures the feed water and

product water total dissolved solids (TDS) in parts per million

(PPM). The lower the TDS the more pure the water is. To check

the TDS press the power button, then press either the IN or

OUT button. The IN button checks the feed water TDS and the

OUT button checks the product water TDS. The meter will auto-

matically turn itself off after a few seconds. The quality meter is

powered by two AAA batteries. To replace the batteries, lift the

meter out of the bracket and remove the back cover.

Figure 2

Inlet Valve

LP Switch

230V

1-Phase

Power Inlet