Installation – Watts LF909 User Manual

Page 3

3

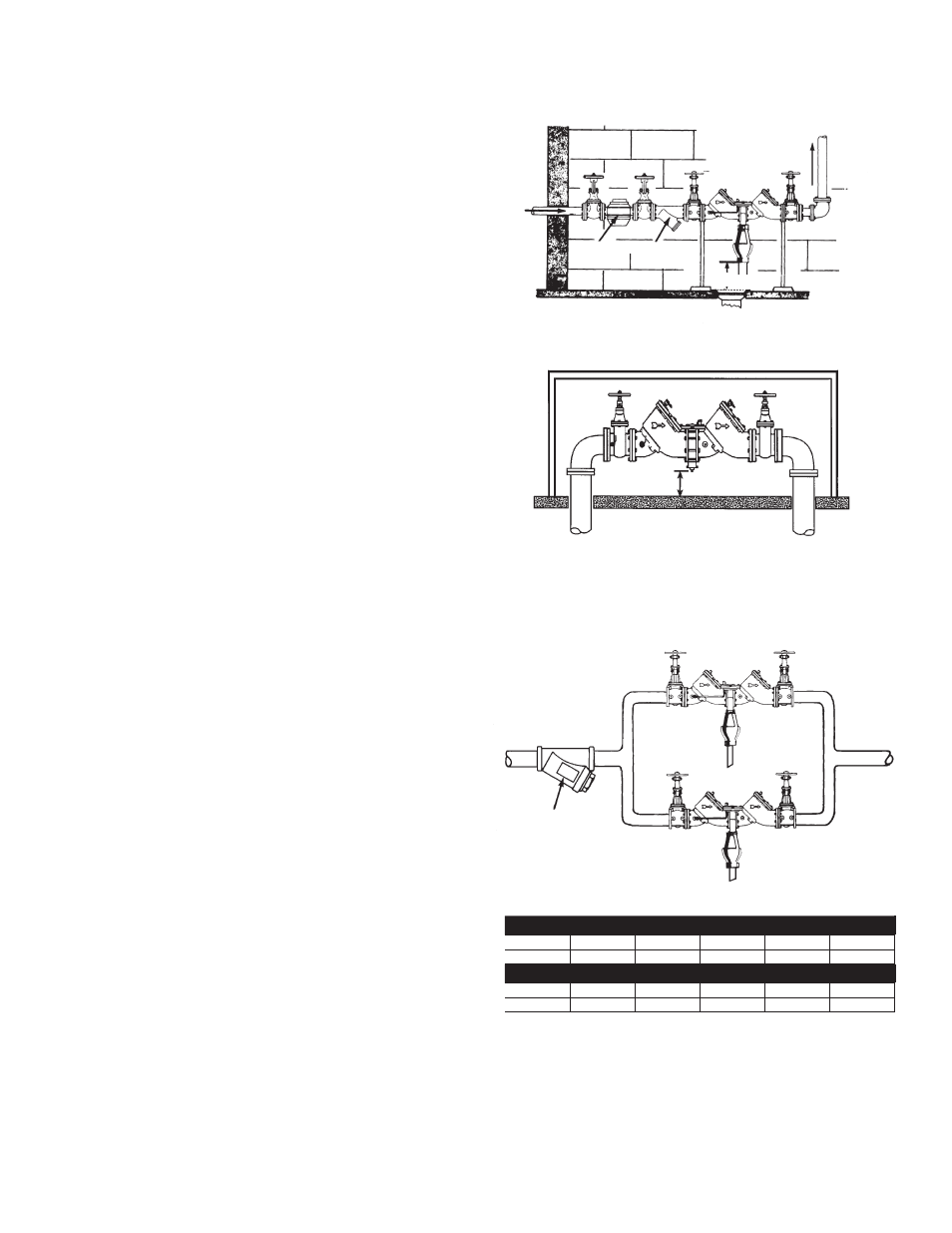

Installation

A. Series 909/LF909 should be installed in a horizontal and upright

position. This positions the relief valve below the first check

valve, enabling the zone to drain through the relief valve outlet.

The shutoff valve with the test cock is to be mounted on the inlet

side of the backflow preventer. The test cock is on the inlet side

of the shutoff valve.

B. The 909/LF909 should always be installed in an accessible loca-

tion to facilitate testing and servicing. Check the state and local

codes to insure that the backflow preventer is installed in compli-

ance, such as the proper height above the ground.

C. Water discharge from the relief valve should be vented in accor-

dance with code requirements. The relief valve should never be

solidly piped into a drainage ditch, sewer or sump. The dis-

charge should be funneled through a Watts air gap fitting piped

to a floor drain.

D. Watts recommends a strainer be installed ahead of Watts 909

Series assemblies to protect the discs from unnecessary fouling.

E. Backflow preventers should never be placed in pits unless abso-

lutely necessary and then only when and as approved by local

codes. Consult your local or state plumbing or health inspector.

Watts recommends installation indoors or above ground in an

insulated enclosure.

Start Up

F. The downstream shutoff should be closed. Open upstream

slowly, fill the valve and bleed the air through Test cock 2, 3 and

4. When valve is filled, open the downstream shutoff slowly and

fill the water supply system. This is necessary to avoid water

hammer or shock damage.

G. The installation of a Watts air gap with the drain line terminating

above a floor drain will handle any normal discharge or nuisance

spitting through the relief valve. However, floor drain size may

need to be designed to prevent water damage caused by a cat-

astrophic failure condition. Do not reduce the size of the drain

line from the air gap fitting.

H. Two or more smaller size valves can be piped in parallel (when

approved) to serve a larger supply pipe main. This type of instal-

lation is employed where increased capacity is needed beyond

that provided by a single valve and permits testing or servicing of

an individual valve without shutting down the complete line.

The number of assemblies used in parallel should be determined by

the engineer’s judgement based on the operating conditions of a

specific installation.

Indoors

Above Ground

Parallel

Now available, WattsBox Insulated Enclosures, for more information, send for ES-WB.

Min. 12” (300mm)

Watts 909/LF909

2

1

⁄

2

" – 10" (65 – 250mm)

Strainer

Air Gap

Watts 909S/LF909S FDA

2

1

⁄

2

” - 10” (65 - 250mm)

Meter

Strainer

Main

Air

Gap

12” (300mm)

support

TaBlE OnE - capaciTy REQuiREd FOR sysTEM

50 GpM

100 GpM

150 GpM

200 GpM

250 GpM

350 GpM

Two

3

⁄

4

"

Two 1"

Two 1

1

⁄

4

"

Two 1

1

⁄

2

"

Two 1

1

⁄

2

"

Two 2"

Devices

Devices

Devices

Devices

Devices

Devices

450 GpM

640 GpM

1000 GpM

2000 GpM

3000 GpM

5000 GpM

Two 2

1

⁄

2

"

Two 3"

Two 4"

Two 6"

Two 8"

Two 10"

Devices

Devices

Devices

Devices

Devices

Devices

Table shows total capacity provided with dual valve installations of various sizes.