Watts LF909 User Manual

Basic installation instructions

RP/IS-909/909RPDA

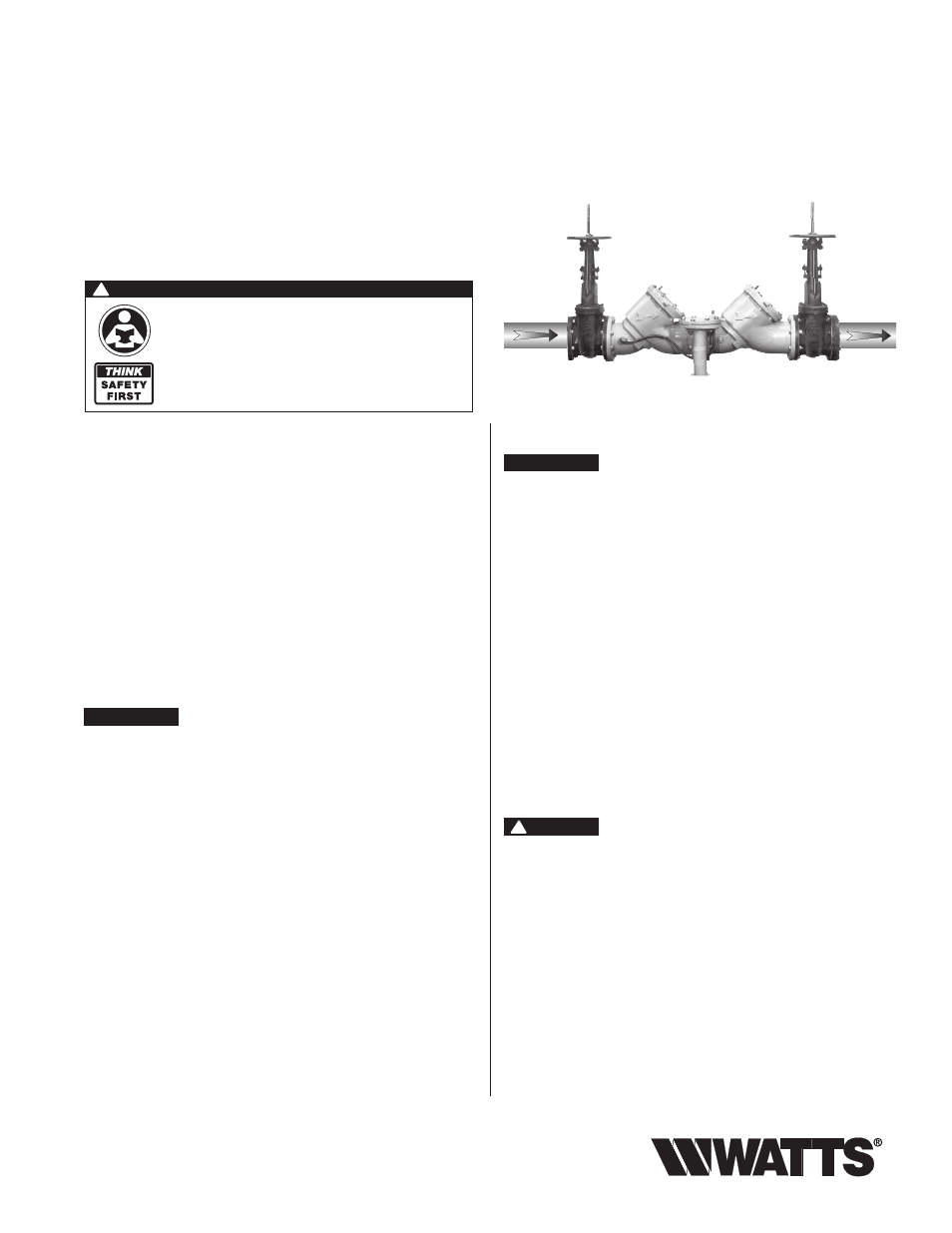

Watts 909 OSY shown

Designed for inline servicing

IMPORTANT:

Inquire with governing authorities for local installa-

tion requirements.

NOTICE

For Australia and New Zealand, line strainers should be installed

between the upstream shutoff valve and the inlet of the backflow pre-

venter.

Its important that this device be tested periodically in compliance

with local codes, but at least once per year or more as service con-

ditions warrant. If installed on a fire sprinkler system, all mechanical

checks, such as alarm checks and backflow preventers, should be

flow tested and inspected internally in accordance with NFPA 13

and NFPA 25.

Testing

For field testing procedure, send for IS-TK-DL,

IS-TK-9A, IS-TK-99E and IS-TK-99D.

For repair kits and service parts, reference PL-RP-BPD at

www.watts.com

For technical assistance, contact your local Watts

representative.

Installation, Maintenance, & Repair

Series 909, LF909, 909RPDA, LF909RPDA

Reduced Pressure Zone Assemblies

Reduced Pressure Detector Assemblies

Sizes: 2

1

⁄

2

" – 10" (65 – 250mm)

Local building or plumbing codes may require modifications to

the information provided. You are required to consult the local

building and plumbing codes prior to installation. If this informa-

tion is not consistent with local building or plumbing codes, the

local codes should be followed.

Need for Periodic Inspection/Maintenance: This product

must be tested periodically in compliance with local codes, but

at least once per year or more as service conditions warrant.

Corrosive water conditions, and/or unauthorized adjustments

or repair could render the product ineffective for the service in-

tended. Regular checking and cleaning of the product’s internal

components helps assure maximum life and proper product

function.

WARNING

!

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information

can result in death, serious personal injury, property

damage, or damage to the equipment.

Keep this Manual for future reference.

Basic Installation Instructions

NOTICE

The flange gasket bolts for the gate valves should be re tight ened

during in stal la tion as the bolts may have loos ened due to stor age

and ship ping.

High Capacity Relief Series:

Location and Installation Considerations

1. Backflow preventers must be installed in high-visibility locations

in order to allow for immediate notice of telltale discharge or

other malfunction. This location should also facilitate testing and

ser vic ing, and protect against freezing and vandalism.

2. Installing a backflow preventer in a pit or vault is not rec om-

mend ed. However, if this becomes necessary, Watts highly rec-

om mends that a licensed journeyman tradesperson, who is rec-

ognized by the authority having jurisdiction, be consulted to

ensure that all local codes and required safety provisions are

met. An air gap below the relief port must be maintained so as

to avoid flooding and submersion of the assembly, which may

lead to a cross connection. *Please refer to Figure No. 1 for fur-

ther information.

3. A strainer should be installed ahead of the backflow preventer to

protect all internal components from unnecessary fouling.

CAUTION

!

Do not install a strainer ahead of the backflow preventer on seldom-

used, emergency water lines (i.e. fire sprinkler lines). The strainer

mesh could potentially become clogged with debris present in the

water and cause water blockage during an emer gen cy.

4. Normal discharge and nuisance spitting are accommodated by

the use of a Watts air gap fitting and a fabricated indirect waste

line. Floor drains of the same size MUST be provided in case of

excessive discharge. *Please refer to Figure No. 1 and Figure

No. 2 for further in for ma tion.

5. When a 909/LF909 Series backflow preventer is installed for

dead-end service applications. (i.e. boiler feed lines, cooling

tower makeup or other equip ment with periodic flow require-

ments), discharge from the relief vent may occur due to water

supply pressure fluctuation during static no-flow con di tions. A

check valve may be required ahead of the backflow preventer.

*Please see “Troubleshooting”, Page 7, prior to installation.