Adjustment information, Sonic omni-beam analog outputs, Power blocks with analog output – Banner U-GAGE Sonic OMNI-BEAM Ultrasonic Sensors User Manual

Page 5: Sensing window adjustment, Negative slope, Positive slope

Adjustment Information

5

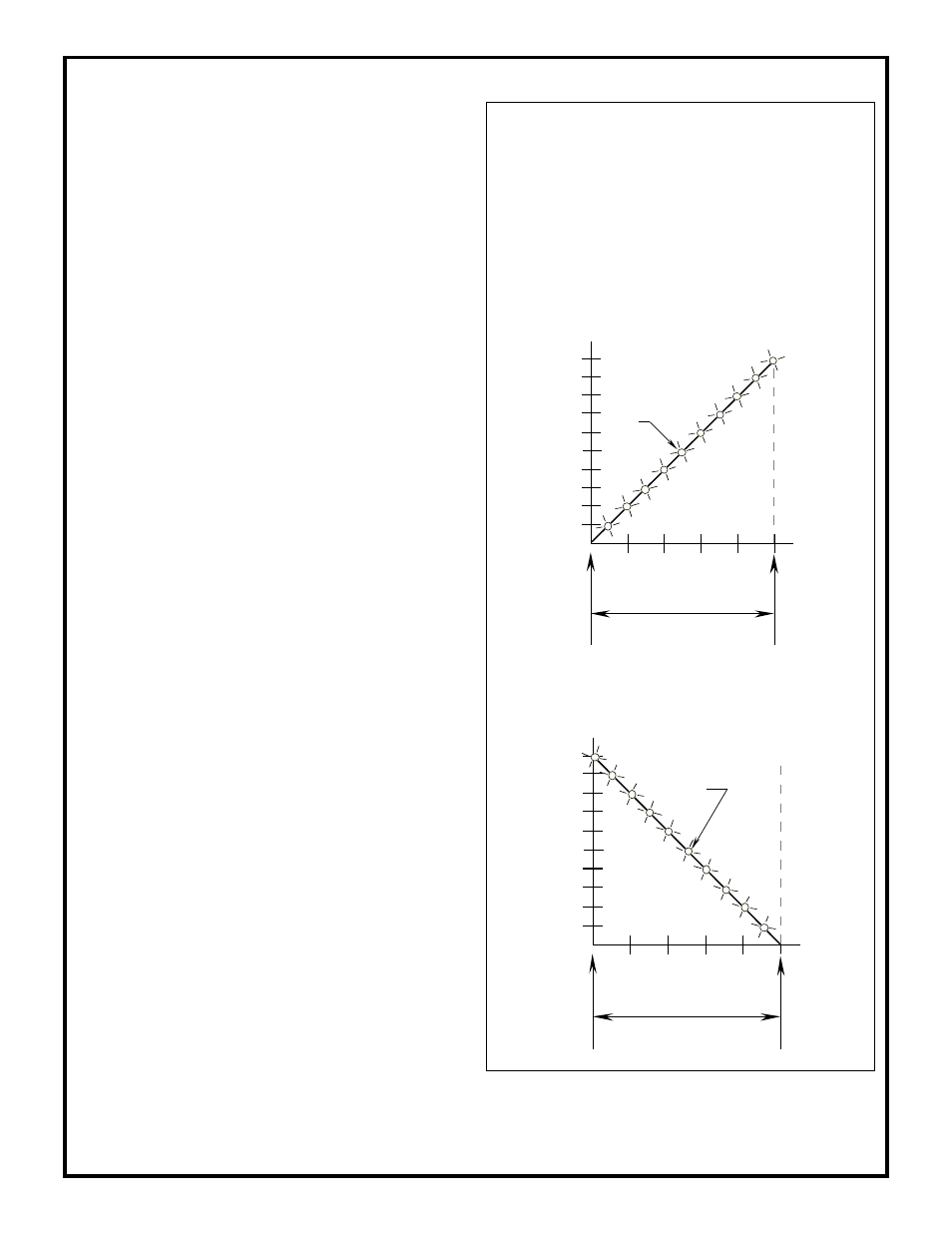

The graphs below show the relationship between the target object

position within the sensing window, the number of LED array

indicators "on", and the analog dc voltage output for sonic

OMNI-BEAM sensor block module model OSBUSR used with

one of the following analog power block modules: OPBA3,

OPBA3QD; OPBB3, OPBB3QD; OPBT3, OPBT3QD. Graphs

for both positive slope and negative slope output are shown.

Power Blocks with ANALOG Output

The programming DIP switches inside the OSBUSR sensor block have

no effect when using analog power blocks. The only adjustments are to

the NEAR and WIDTH potentiometers. Note: The status of the LOAD

indicator LED should be disregarded when a sensor with an analog

power block is being adjusted.

Sensing Window Adjustment

A dc voltmeter is used to locate and to "size" the sensing window. The

NEAR and FAR limit adjustments on top of the sensor head (see photo

on page 4) are 15-turn potentiometers, clutched at both ends of travel.

They are adjusted using a small, flat-blade screwdriver. Clockwise

rotation of either limit adjustment moves that window limit farther

away from the sensor. Counterclockwise rotation moves that limit

closer to the sensor.

Refer to the hookup drawings for ANALOG output power blocks on

page 3. If the positively-sloped power block output (black wire) is used,

the analog value of the output increases from 0 to +10 volts dc as the

sensor-to-target distance increases. If the negatively-sloped power

block output (white wire) is used, the analog value of the output

decreases from +10 to 0 volts as the sensor-to-target distance increases.

The window width may be set at from 3 inches to 22 inches. This

sensing window may be placed anywhere within the 4 to 26 inch sensing

range of the OSBUSR sensor block. NOTE: The NEAR limit may be

referenced as close as zero inches (i.e. zero inches equals zero volts or

+10 volts output); however, sensing is not reliable within the first 4

inches from the transducer face.

The factory settings are:

Near limit (NEAR control) = 0 inches

Far limit (WIDTH control) = 26 inches

With these settings, the voltage at the minimum sensing range (4 inches)

will be approximately 1.6V dc (positive slope selected) or 9.4V dc

(negative slope selected).

Window adjustment procedure:

1) Remove the transparent plastic top cover of the sensor head for

access to the NEAR and WIDTH adjustments. Connect a dc voltmeter

across either the black and yellow wires or the white and yellow wires

of the cable (depending upon the output to be used) with or without the

load connected. Connect the brown and blue power supply wires from

the cable to a suitable power source and apply power.

2) Position the target material at the desired near limit of the sensing

window. Rotate the NEAR limit control to the point where the output

voltage just equals 0.0 V dc (black and yellow output wires in use,

positive slope) or 10.0V dc (white and yellow output wires used,

negative slope). For positive slope adjustment, rotate the control

clockwise to decrease the voltage; rotate counterclockwise to increase

the voltage. For negative slope adjustment, rotate counterclockwise to

decrease and clockwise to increase.

3) Move the target material to the desired far limit of the sensing

window and rotate the WIDTH control to find the point at which the

output voltage just equals 10.0 V dc (positive slope) or 0.0V dc

(negative slope). For positive slope adjustment, rotate the control

clockwise to decrease the voltage; rotate counterclockwise to increase

the voltage. For negative slope adjustment, rotate counterclockwise to

decrease and clockwise to increase.

4) Reposition the target material at the near limit and readjust the

NEAR limit control, if necessary, to re-establish the correct dc output

(repeat step #2).

5) If any adjustment was necessary in step #4, recheck the far limit and

readjust the WIDTH control (repeat step #3), if necessary.

Sonic OMNI-BEAM Analog Outputs

0

2

4

6

8

10

1

3

5

7

9

Near Limit

Far Limit

Sensing Window Width

Output (V dc)

10

9

8

7

6

5

2

1

Position Indicator

LEDs

3

4

Negative slope

Negative slope:

output voltage decreases with target distance

Near Limit

Far Limit

Sensing Window Width

Output (V dc)

10

9

8

7

6

5

4

3

2

1

Position Indicator

LEDs

0

2

4

6

8

10

1

3

5

7

9

Positive slope

Positive slope:

output voltage increases with target distance

6) The moving-dot LED display will confirm the window dimen-

sions by indicating the relative position of the target within the

established window, in 10% increments.