Q60v series adjustable-field sensors, Visible red emitter, Sensor setup – Banner Q60 Background Suppression Series User Manual

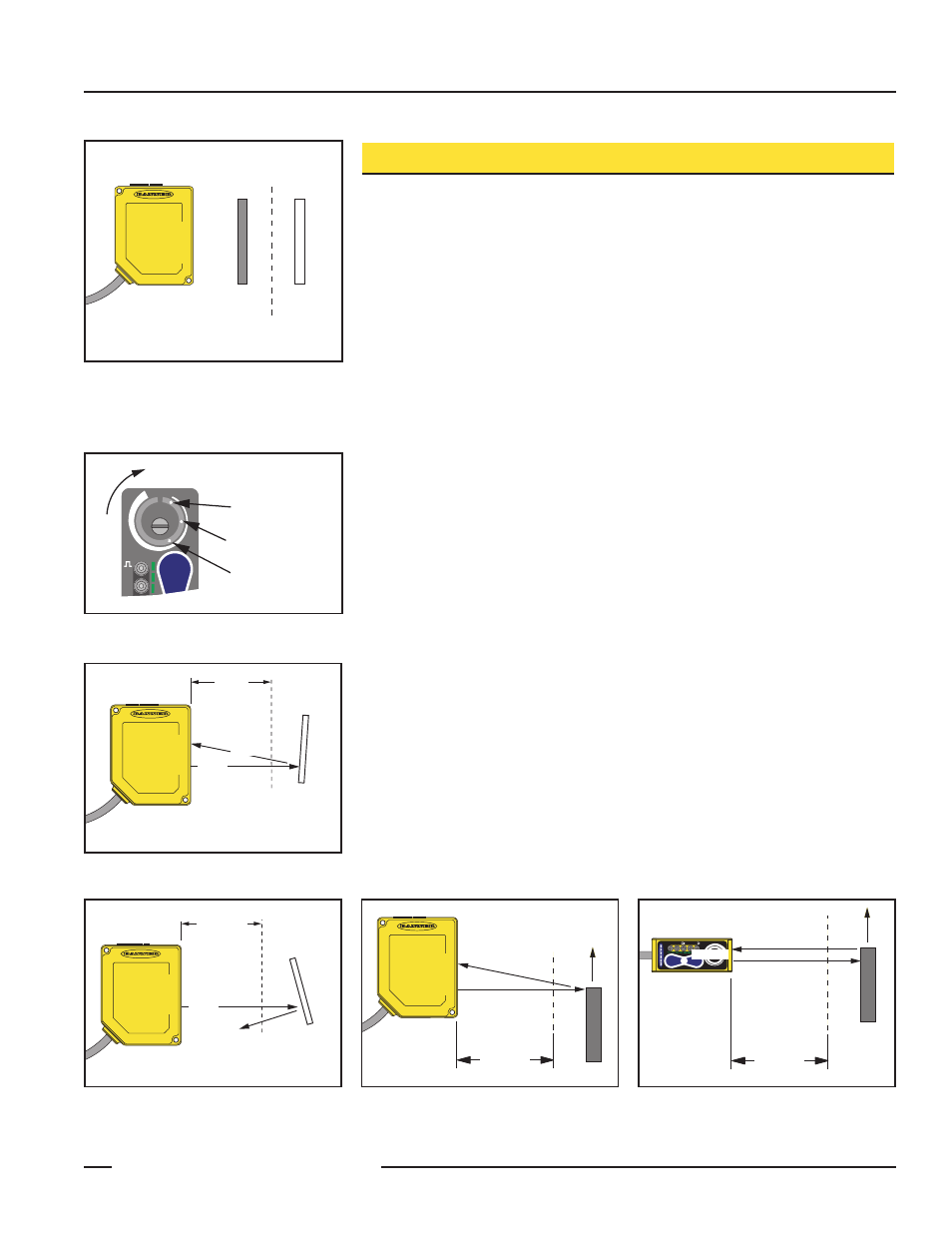

Page 3: Figure 6. reflective background – problem, Figure 7. reflective background – solution, Figure 9. object beyond cutoff distance — solution

page

3

Q60V Series Adjustable-Field Sensors –

Visible Red Emitter

Banner Engineering Corp.

•

Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Sensor Setup

Setting the Cutoff Distance

The cutoff distance for Q60AFV sensors may be adjusted between 200 mm and

1000 mm (8" to 40").

To maximize contrast, position the lightest possible background to be used, at the

closest position it will come to the sensor during use (Figure 4). Using a small

screwdriver in the adjustment screw, adjust the cutoff distance until the threshold is

reached and the green Light Sensed indicator changes state. (If the indicator never

comes ON, the background is beyond the maximum sensing cutoff and will be

ignored.) Note the position of the rotating cutoff position indicator at this position.

Then repeat the procedure, using the darkest target, placed in its most distant

position for sensing. Adjust the cutoff so that the indicator is midway between the two

positions (Figure 5).

NOTE: Setting the cutoff distance adjustment screw to its maximum clockwise

position places the receiver lens directly in front of the receiver elements and

results in the Q60 performing as a long-range diffuse sensor.

Sensing Reliability

For highest sensitivity, the sensor-to-object distance should be such that the object

will be sensed at or near the point of maximum excess gain. The excess gain curves

on page 1 show excess gain vs. sensing distance for 200 mm and 1 m cutoffs.

Maximum excess gain for a 200 mm cutoff occurs at a lens-to-object distance of

about 150 mm, and for a 1 m cutoff, at about 400 mm. The background must be

placed beyond the cutoff distance. Following these two guidelines makes it possible

to detect objects of low reflectivity, even against close-in reflective backgrounds.

Background Reflectivity and Placement

Avoid mirror-like backgrounds that produce specular reflections. False sensor re-

sponse will occur if a background surface reflects the sensor’s light more strongly to

the near detector (R1) than to the far detector (R2). The result is a false ON condition

(Figure 6). Use of a diffusely-reflective (matte) background will cure this problem.

Other possible solutions are to angle either the sensor or the background (in any

plane) so that the background does not reflect back to the sensor (see Figure 7).

An object beyond the cutoff distance, either moving or stationary (and when posi-

tioned as shown in Figure 8), can cause unwanted triggering of the sensor because it

reflects more light to the near detector than to the far detector. The problem is easily

remedied by rotating the sensor 90° (Figure 9) to align the sensing axis horizontally.

The object then reflects the R1 and R2 fields equally, resulting in no false triggering.

Figure 6. Reflective background – problem

Cutoff

Distance

Reflective

Background

Sensing

Field

E

R2

R1

E =

Emitter

R1 = Near Detector

R2 = Far Detector

Core of

Emitted

Beam

Strong

Direct

Reflection

to R1

Figure 7. Reflective background – solution

E

R2

R1

E =

Emitter

R1 = Near Detector

R2 = Far Detector

Cutoff

Distance

Reflective

Background

Strong

Direct

Reflection

Away From

Sensor

Sensing

Field

Core of

Emitted

Beam

Target

Background

Cutoff

Distance

E

R2

R1

Figure 4. Set cutoff distance approximately

midway between the farthest

target and the closest background

ON

DELAY

DO

RANGE

In

cr

e

a

si

ng

Di

st

an

ce

Set Cutoff Midway

Between

Farthest Target Object

Closest Background

Figure 5. Setting the cutoff distance

Figure 8. Object beyond cutoff distance —

problem

Sensing

Field

Cutoff

Distance

E

R2

R1

Figure 9. Object beyond cutoff distance —

solution

Sensing

Field

ON

OFF

DELA

Y

DELA

Y

DO

SIG

LO

RANGE

E, R1, R2