Iguration, 2 configuration of tiamo, 1 devices – Metrohm TitrIC 4 User Manual

Page 11: 2 swing head configuration, 3 special beaker definition, 4 lift positions

Application Bulletin 318 e

Installation Instructions of TitrIC 4

Page 11/16

6.2 Configuration of tiamo

TM

Æ The controller cable (6.2151.000), which is already connected to the 905, is now connected to an

USB interface on the PC. Wait a few seconds. The driver installation for 905 and 815 follows. It’s not

necessary to start windows update, click on

automatic installation of the software

for both.

Æ The controller cable (6.2151.000), which is already connected to the 856 conductivity module, is now

connected to an USB interface on the PC

Æ tiamo

TM

2.1 is started

6.2.1 Devices

Connected USB devices are automatically recognized when tiamo

TM

is started. After confirmation of the

automatically generated request the devices are stored in the configuration. Keep the proposed device

names.

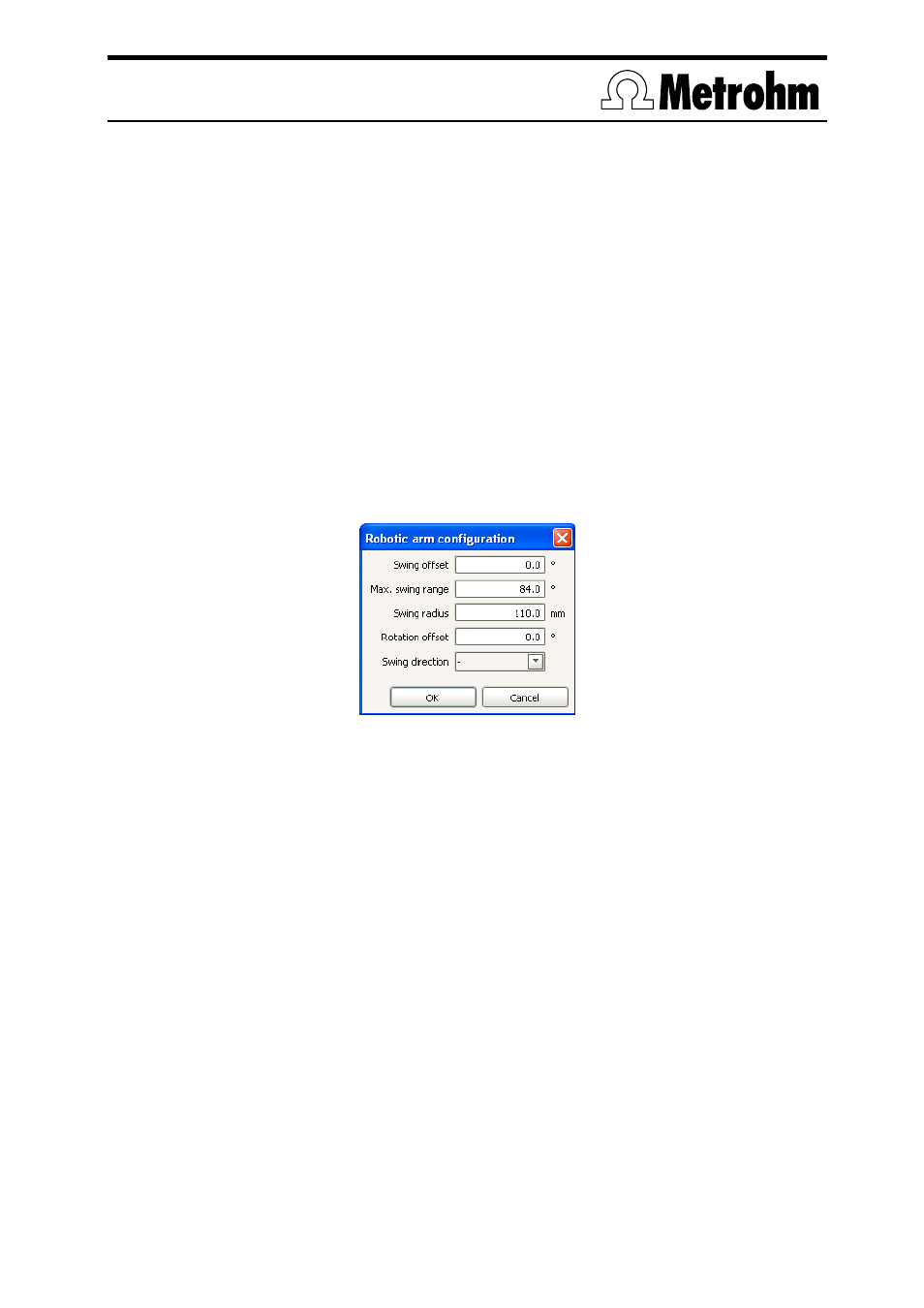

6.2.2 Swing Head configuration

Under

Configuration

at the top left, double-click on

815_1

under

Devices

, click on the entry

Tower 1

, set the

Axial distance

to 196.0 mm and in the middle of the window under

Swing Head

click on

Configuration

and

Yes

and then enter the following values:

Configuration of the Swing Head for Titration head 6.1462.050

Confirm the entries twice with <

OK>

and then mark

815_1

under

Devices

and click on

Edit /

Initialize

. Wait

until the initialization has been finished. The titration head (6.1462.050) can now be mounted on the

Swing Head.

6.2.3 Special beaker definition

Under

Configuration

mark

815_1

, select

Edit / Properties / Rack / Rack data / Special beaker

,

Special beaker 1

, click

on

Edit

and define the position to be used for rinsing as

Rack position

. The last position on the rack is

normally used as the rinsing position. A sample vessel containing DI water should always stand in this

position. Confirm by clicking on

twice.

6.2.4 Lift

positions

Under

Configuration / Tools / Manual operation

click on

815 Sample Changer / Tower 1

in the left-hand column

and use the entries

Move

and

Assign position

(See 815 Instructions for Use, page 47) to define suitable

values (click on

each time) for:

Shift position

for changing the rack position (approx. 53 mm)

Work position

for aspirating of the sample (approx. 173 mm)

Special position

for dipping for the conductivity measurement (approx. 130 mm)

For the special position, you must define the work position again, then at the right beside

Work position

click on

Tower

and select

Special position 1

. Confirm these settings with a click on

close

.