Controls, Operation – Briggs & Stratton 10000 Watt User Manual

Page 15

15

11. Push and hold MANUAL OVER-RIDE button on control

panel again until engine stops.

IMPORTANT: DO NOT proceed until you are certain that

generator AC voltage and frequency are correct and within

the stated limits. To obtain the proper generator frequency,

see Engine Adjustments.

Engine Adjustment

There are regional variances in the composition of natural

gas. Each home generator unit leaves the factory set for

NG operation. If the generator output voltage or frequency

measured during Initial Start-Up (paragraph #9) is outside

the listed ranges, the combustibility of the gas supplied at

the installation site may be substantially different from the

fuel used at the factory.

To adjust the engine for this difference, proceed as follows.

1. Remove the oil drain and control panel access covers.

2. Connect an accurate frequency meter to the line side of

the generator’s main circuit breaker.

3. Ensure that the 15 Amp fuse is installed.

4. Set the generator’s main circuit breaker ON.

5. Set the generator’s system switch to AUTO.

6. Push MANUAL OVER-RIDE button on control panel.

When the engine starts, allow it to warm up for five

minutes.

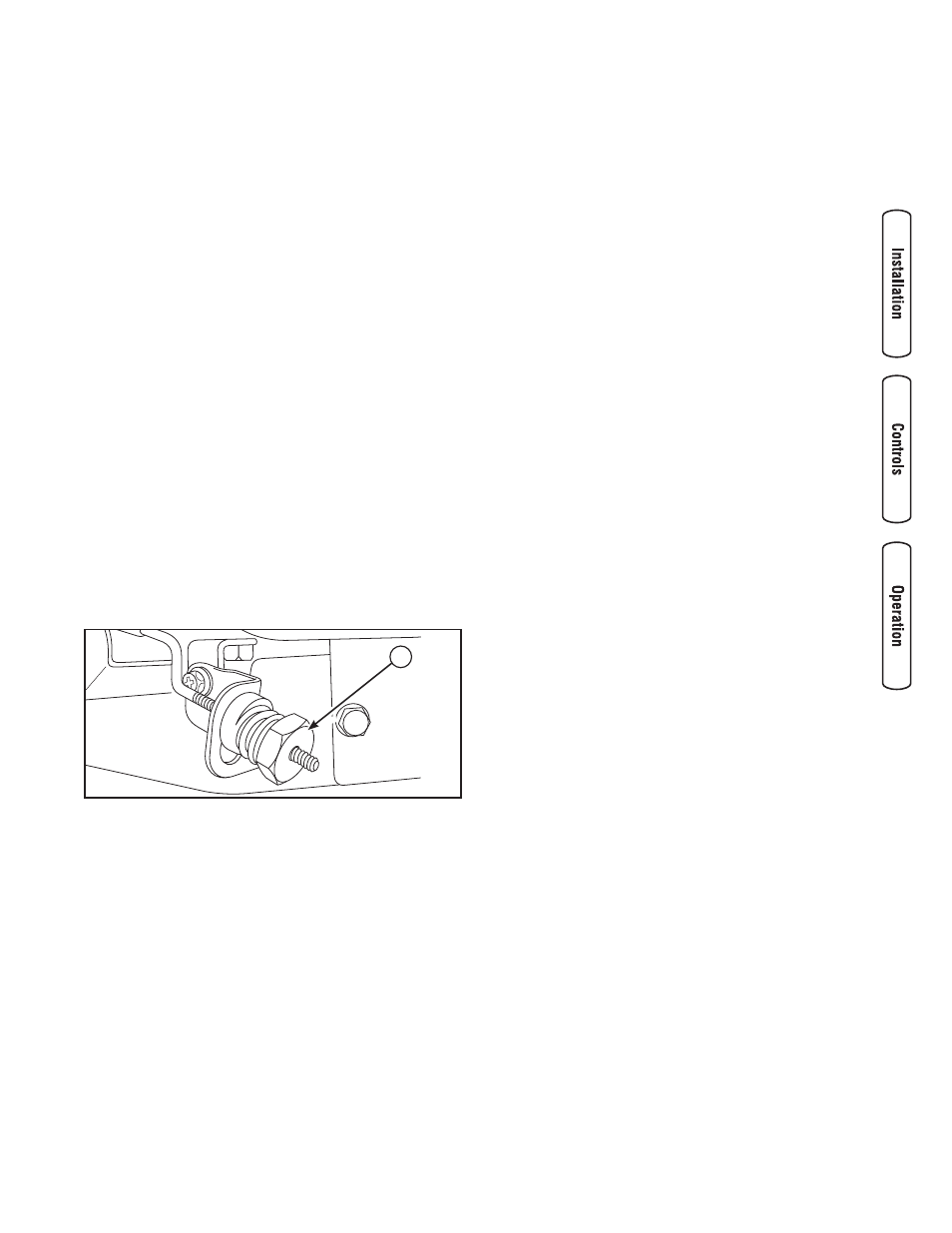

7. Normal no load frequency is 62.0 to 62.5 Hz. If

adjustment is needed at no load, slowly rotate

the governor adjustment nut (A) clockwise and/or

counterclockwise until frequency is 62.0 to 62.5 Hz.

8. Push and hold MANUAL OVER-RIDE button on control

panel again until engine stops.

9. Turn the service disconnect to the transfer switch off.

After a short time delay, the transfer switch will connect

to the generator.

10. Load generator to full load.

11. Connect an accurate frequency meter to the load side of

the generator’s main circuit breaker. Frequency should

be above 57.0 Hz.

12. If frequency is below 57.0 Hz, slowly rotate the

governor adjustment nut or screw clockwise and/or

counterclockwise until frequency is above 57.0 Hz.

13. Turn the service disconnect to the transfer switch on.

The transfer switch will connect to the utility after five

minutes.

14. After the engine has stopped running,

• If an adjustment was made in step 12, repeat steps

3 through 8.

• If an adjustment was not made in step 12, proceed

to step 15.

IMPORTANT: If the no load frequency falls out of the no

load parameter after full load adjustment is made, contact an

authorized service center.

15. Install the oil drain and control panel access covers.

Controls

See the Operator’s Manual for complete description of the

home generator controls.

Operation

Automatic Operation Sequence

The generator’s control panel houses a logic control circuit

board. This control board constantly monitors utility power

source voltage. Should that voltage drop below a preset

level, control board action will signal the engine to crank and

start.

When utility source voltage is restored above a preset

voltage level, the engine is signaled to shut down.

The actual system operation is not adjustable and is

sequenced by sensors and timers on the control board, as

follows:

Utility Voltage Dropout Sensor

• This sensor monitors utility source voltage.

• If utility source voltage drops below about 70 percent

of the nominal supply voltage, the sensor energizes a

10 second timer. The timer is used to ‘sense’ brown-

outs.

• Once the timer has expired, the engine will crank and

start.

Utility Voltage Pickup Sensor

This sensor monitors utility power supply voltage. When that

voltage is restored above 80 percent of the nominal source

voltage, a time delay starts timing and the engine will go to

engine cool-down.

Engine Cool-down Timer

• When the load is transferred back to the utility power

source, the engine cool-down timer starts timing.

• The timer will run for about one minute, then the

generator will stop.

• Minimum engine run time is 5 minutes.

A