Notice, Warning – Briggs & Stratton 10000 Watt User Manual

Page 14

14

BRIGGSandSTRATTON.COM

Final Installation Considerations

Engine Oil

notice

Any attempt to crank or start the engine before it has been

properly serviced with the recommended oil will result in

equipment failure.

Refer to Maintenance and engine manual for oil fill

information.

Damage to equipment resulting from failure to follow this

instruction will void engine and generator warranty.

•

•

This engine is shipped from the factory pre-run and filled

with synthetic oil (API SJ/CF 5W-30W). This allows for

system operation in the widest range of temperature and

climate conditions. Before starting the engine, check oil level

and ensure that engine is serviced as described in the engine

operator’s manual.

NOTE: The use of synthetic oil does not alter the required oil

change intervals described in the engine operator’s manual.

Battery

The installer must supply and install a 350 CCA (cold

cranking amps), sealed, valve-regulated, lead-acid

rechargeable 12 Volt DC, AGM type, starting battery.

NOTE: DO NOT use a deep-cycle or automotive type battery.

Install the battery as described in Servicing the Battery in the

Maintenance section of the operator’s manual. Always make

sure the negative cable is hooked up last.

The battery may not be at full charge when installed. If

battery voltage is below 12 Volts, charge the battery. See

Battery in Maintenance of the operator’s manual for details.

WARNING

Battery posts, terminals and related accessories contain

lead and lead compounds, chemicals known to the State

of California to cause cancer and reproductive harm.

Wash hands after handling.

Fuel Supply System

Ensure that all fuel pipe connections are tight, secure and

without leaks.

Ensure that all gas line shutoff valves are OPEN and that

adequate fuel pressure is available whenever automatic

operation is desired.

Fuel System Selection

The engine of your Home Generator System is factory

calibrated to run on natural gas (NG). It may also be

operated on liquefied petroleum (LP) vapor. There is no

additional hardware/equipment required to switch between

either fuel. However, LP fuel inlet pressure must be between

11 and 14 inches water column.

To configure the fuel system for LP use:

1. Remove control panel and oil fill access covers.

2. Set generator’s system switch to OFF.

3. Remove 15 Amp fuse from control panel.

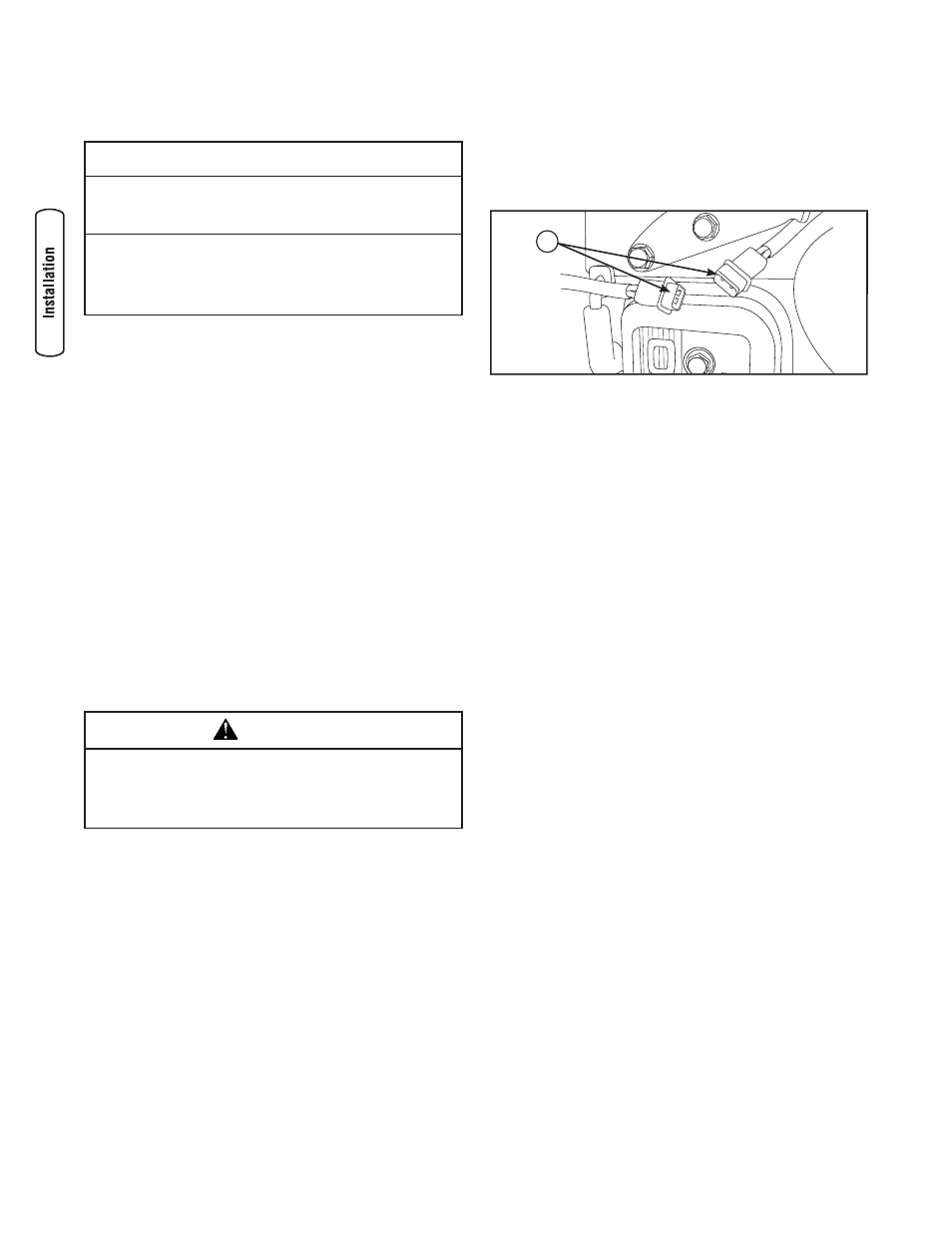

4. Connect the fuel select solenoid by joining the two-pin

electrical connector (A).

5. Reinstall 15 Amp fuse in control panel.

6. Set generator’s system switch to AUTO.

7. Install control panel and oil fill access covers.

The system is now ready to operate automatically using LP

fuel. With a fixed main jet for LP gas, there is no need to

perform any engine adjustments for LP operation.

Initial Start-up (No Load)

Before operating the home generator or placing it into

service, inspect the entire installation carefully.

Then begin testing the system without any electrical loads

connected, as follows:

1. Set generator’s main circuit breaker to its ON (closed)

position.

2. Install 15 Amp fuse in control panel.

3. Set generator’s system switch to AUTO.

4. Push MANUAL OVER-RIDE button on control panel.

NOTE: When the home generator is started for the very

first time, it will require that air in the gaseous fuel lines be

purged. This may take a few minutes.

5. DO NOT crank engine for more than 10 seconds, then

pause for 10 seconds to reduce heat in the starter.

6. Repeat process until engine starts.

7. Listen for unusual noises, vibration or other indications of

abnormal operation. Check for oil leaks while engine runs.

8. Let engine warm up for about five minutes to allow

internal temperatures to stabilize.

9. Connect an accurate AC voltmeter and a frequency

meter to check generator output at load side of circuit

breaker. Voltage should be 239-262 Volts, frequency

should be 62.0 - 62.5 Hz.

NOTE: If either parameter is outside these ranges, perform

the Engine Adjustments described below.

10. Check generator output between one of the generator

connection lugs and the neutral lug, then between the

other generator connection lug and the neutral lug.

In both cases, voltage reading should be between

119-131 Volts.

A