Appendix d, Appendix e – Calculated Industries 4095-C User Guide User Manual

Page 56

U

ser

’

s

G

Uide

— 57

aPPEndix d –

Constants

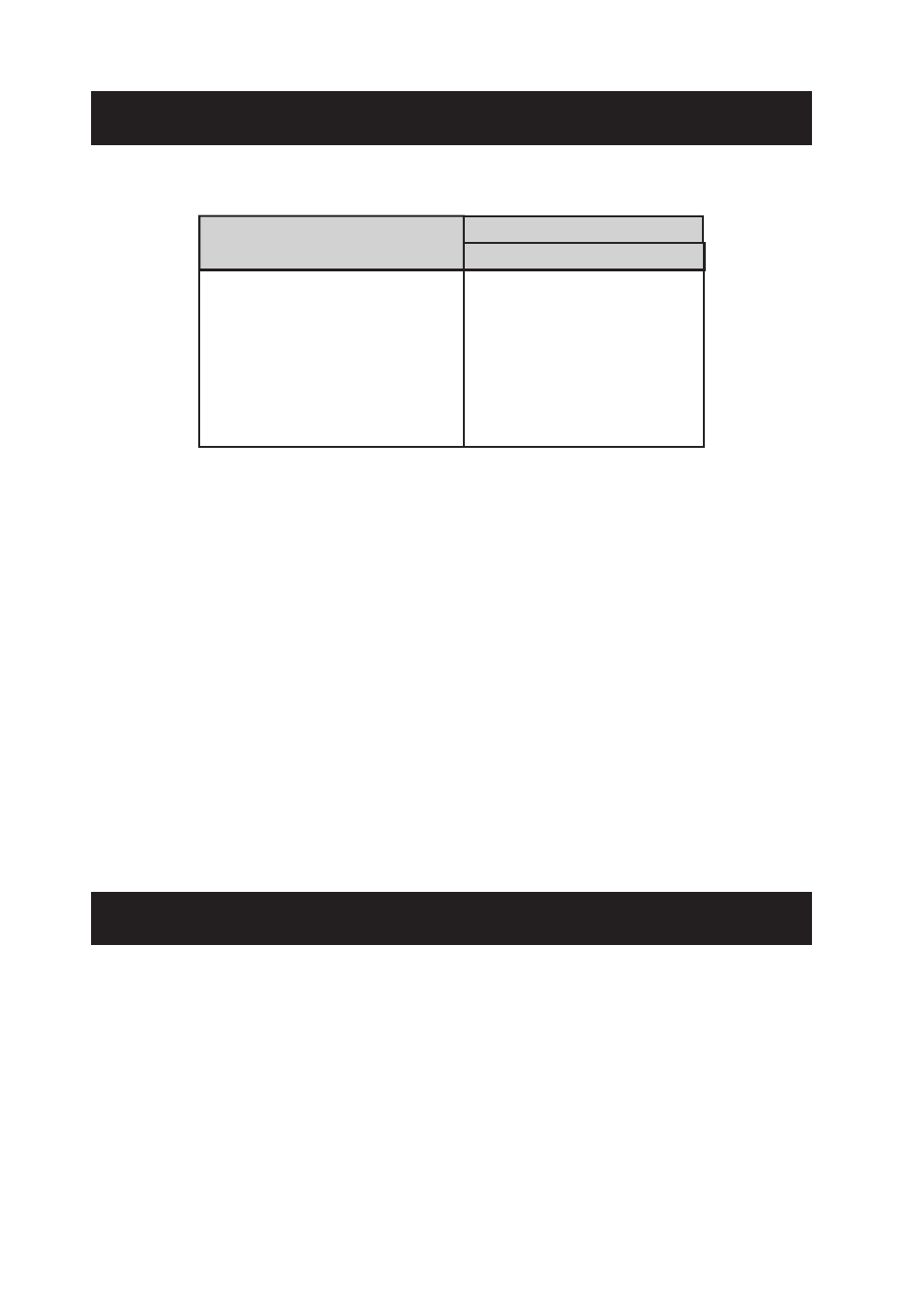

For material surface roughness, we use the following:

Material

PVC

Copper

Steel (low carbon)

Stainless Steel (austenitic)

Brass

Aluminum

Cast Iron

15.6

4.9

221

49.2

4.9

4.9

850

e (x 10

-6

ft)

Roughness Factor

For water properties:

Viscosity = 0.001 Pascal-seconds

Density = 1000 kg/m³

Depending upon flow type and Reynolds Number value, we use

one of the following methods for computing Pressure Loss:

1) Laminar Flow method (if Reynolds Number < 3,000)

2) Smooth Pipe method (if Reynolds Number > 3,000 and

Boundary Layer Thickness < Pipe Roughness)

3) Prandtl equation method (if Reynolds Number < 100,000

and Pipe Roughness > Boundary Layer Thickness)

4) Karman Equation method (all other conditions)

aPPEndix E –

Care Instructions

Please follow the guidelines listed in this section for proper care

and operation of your calculator. Not following the instructions

listed below may result in damage not covered by your

warranty. Refer to the Repair and Return section on page 62 for

more details.

Do not expose calculator to temperatures outside the

operating temperature range of 32ºF – 104ºF (0ºC – 40ºC).

Do not expose calculator to high moisture such as

submersion in water, heavy rain, etc.