Adjusting the notch frequency, Cavity tuning tip, Passband – Bird Technologies 20-70-26 User Manual

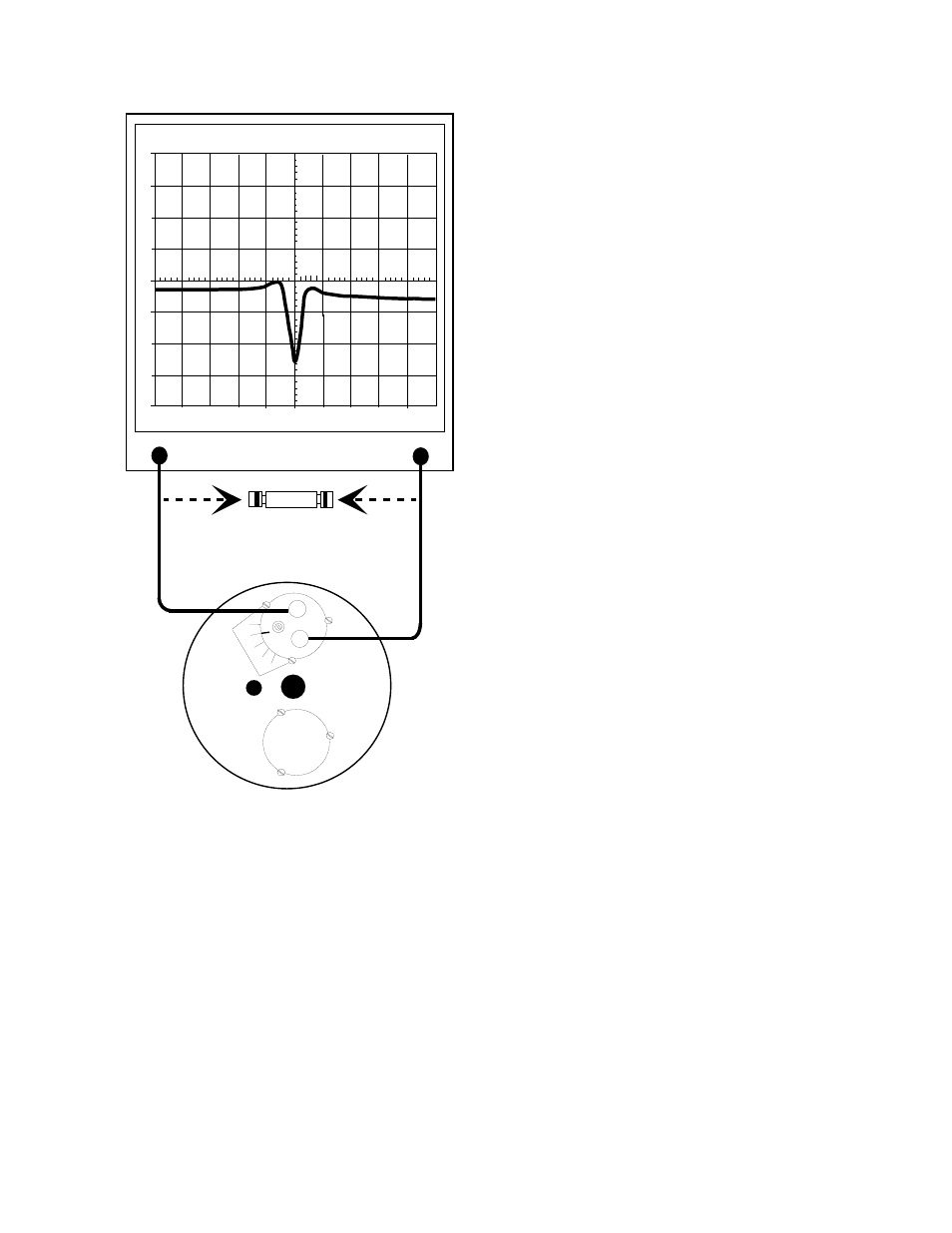

Page 8: Figure 6: checking notch depth and notch frequency

(calibrated by factory). Rotating the loop plate

assembly and moving the calibration mark above 0

causes the notch depth to be increased. It is

adjustable across a useable range of from 15 dB to

25 dB.

Adjusting the notch frequency

The notch depth should be checked and adjusted

prior to adjusting the notch frequency. The

procedure for checking the notch frequency

appears on page 3. Adjustment is made by first

setting the fine tuning knob at it's mid-point. Then

setting the peak (minimum value) of the response

curve to the desired frequency (should be the

center-vertical graticule line on the IFR A-7550's

display). See figure 6.

The resonant frequency is adjusted by using the

coarse tuning rod, which is a sliding adjustment

(invar rod) that rapidly tunes the response curve

across the frequency range of the filter. Resonant

frequency is increased by pulling the rod out of the

cavity and is decreased by pushing the rod into the

cavity. Additionally, the fine tuning rod, also a

sliding adjustment (silver-plated-brass rod), allows

a more precise setting of the frequency after the

coarse adjustment is made. The frequency is

increased by pushing the fine tuning rod in and is

decreased by pulling it out, the exact opposite of

the coarse tuning rod.

Once the desired response is obtained using the

coarse and fine tuning rods, they are "locked" in

place. The coarse rod is secured by tightening the

10-32 cap screw (5/32 hex wrench required) and

the fine tuning rod is held in place by tightening the

knurled thumb nut. Failure to lock the tuning

rods will cause a loss of temperature

compensation and detuning of the cavity.

Cavity Tuning Tip

When tuning a cavity that has been in service for

some time it is not unusual to find the main tuning

rod hard to move in or out. This occurs because

TX RX Systems Inc. uses construction techniques

borrowed from microwave technology that provide

large area contact surfaces on our tuning probes.

These silver plated surfaces actually form a

pressure weld that maintains excellent conductivity.

The pressure weld develops over time and must be

broken in order for the main tuning rod to move.

This is easily accomplished by gently tapping the

tuning rod with a plastic screwdriver handle or

small hammer so it moves into the cavity. The

pressure weld will be broken with no damage to the

cavity.

PASSBAND

The passband is the frequency range over

which the return loss is 15 dB or greater.

Because the passband will vary with the tuning of

the notch frequency it should be the last

adjustment made to the Series-Notch filter. The

passband is adjusted by changing the amount of

capacitance in the loop plate assembly. The

capacitor is variable and is either an air-plate or a

tubular-piston type depending upon the frequency

TX RX Systems Inc. Manual 7-9146-1 07/25/96 Page 4

0

1

MHZ / DIV

MHZ

98.00

300

KHZ RES

50

dB

ATT

GEN

dBM

0

10

MSEC

ANALYZER

GENERATE

10

20

30

40

dB

-10

-20

-30

-40

FEMALE UNION

Used to set 0 dB reference

0

5

10

15

20

Series-Notch

Filter

Figure 6: Checking notch depth and notch frequency.