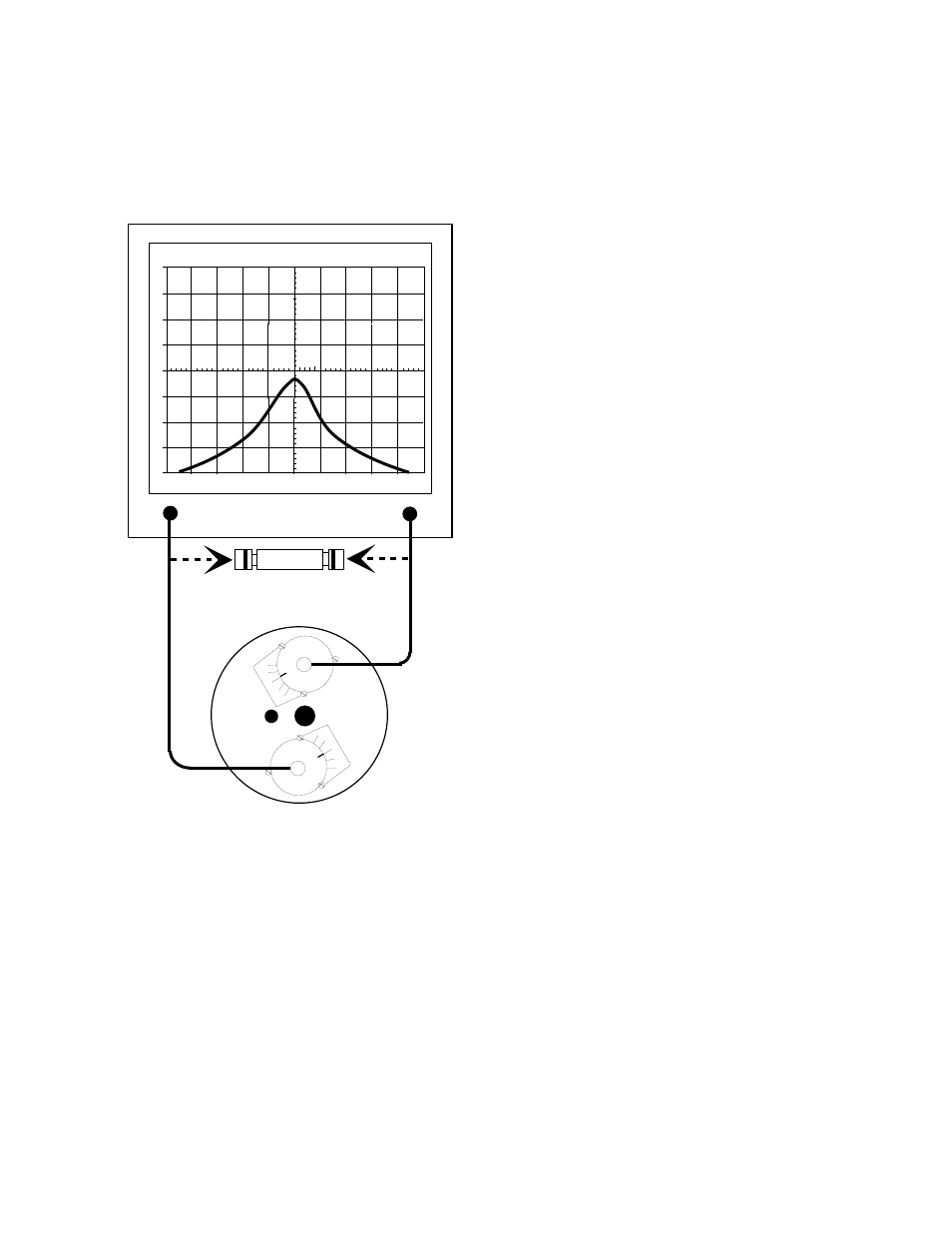

Figure 3: checking cavity tuning – Bird Technologies 11-70 Series User Manual

Page 7

2. The resonant frequency of the filter is checked

by connecting the tracking generator to the in-

put of the cavity filter while the spectrum ana-

lyzer is connected to the output, as shown in

figure 3.

3. Insure the IFR A-7550 menu's are set as fol-

lows:

DISPLAY - line

MODE - live

FILTER - none

SETUP - 50 ohm/dBm/gen1.

4. Set the fine tuning knob at it's mid-point. Adjust

the pass frequency by setting the peak (mini-

mum loss value) of the response curve to the

desired frequency (should be the center-vertical

graticule line on the IFR A-7550's display). See

figure 3. The resonant frequency is adjusted by

using the coarse tuning rod, which is a sliding

adjustment (invar rod) that rapidly tunes the fil-

ter's response curve. The resonant frequency is

increased by pulling the rod out of the cavity

and is decreased by pushing the rod into the

cavity. Additionally, the fine tuning rod, also a

sliding adjustment (silver-plated-brass rod ), al-

lows a more precise setting of the response

curve after the coarse adjustment is made. The

resonant frequency is increased by pushing the

fine tuning rod in and is decreased by pulling it

out, the exact opposite of the coarse tuning rod.

5. Once the desired response is obtained using

the coarse and fine tuning rods, they are

"locked" in place. The coarse rod is secured by

tightening the 10-32 cap screw and the fine

tuning rod is held in place by tightening the

knurled thumb nut. Failure to lock the tuning

rods will cause a loss of temperature compen-

sation and detuning of the cavity.

Cavity Tuning Tip

When tuning a cavity that has been in service for

some time it is not unusual to find the main tuning

rod hard to move in or out. This occurs because

TX RX Systems Inc. uses construction techniques

borrowed from microwave technology that provide

large area contact surfaces on our tuning probes.

These silver plated surfaces actually form a

pressure weld that maintains excellent conductivity.

The pressure weld develops over time and must be

broken in order for the main tuning rod to move.

This is easily accomplished by gently tapping the

tuning rod with a plastic screwdriver handle or

small hammer so it moves into the cavity. The

pressure weld will be broken with no damage to the

cavity.

Measuring and Adjusting Insertion Loss

1. A zero reference must first be established at the

IFR A-7550 before the insertion loss can be

measured. This is accomplished by temporarily

placing a "female union" between the generator

output and analyzer input, see figure 3.

2. The flat line across the screen is the generator's

output with no attenuation, this value will be-

come our reference by selecting the "Mode"

main menu item and choosing the "Store"

command.

3. Next select the "Display" main menu item and

choose the "Reference" command. This will

TX RX Systems Inc. Manual 7-9145-1 08/05/96 Page 3

0

2

-2

-4

-6

-8

4

6

8

50

KHZ / DIV

MHZ

98.00

300

KHZ RES

dB

40

dB

ATT

GEN

dBM

0

10

MSEC

ANALYZER

GENERATE

FEMALE UNION

Used to determine 0 dB reference.

0

5

10

15

20

BANDPASS

FILTER

0

5

10

15

20

Figure 3: Checking cavity tuning.