Bendix Commercial Vehicle Systems GEN 5 ABS User Manual

Page 11

11

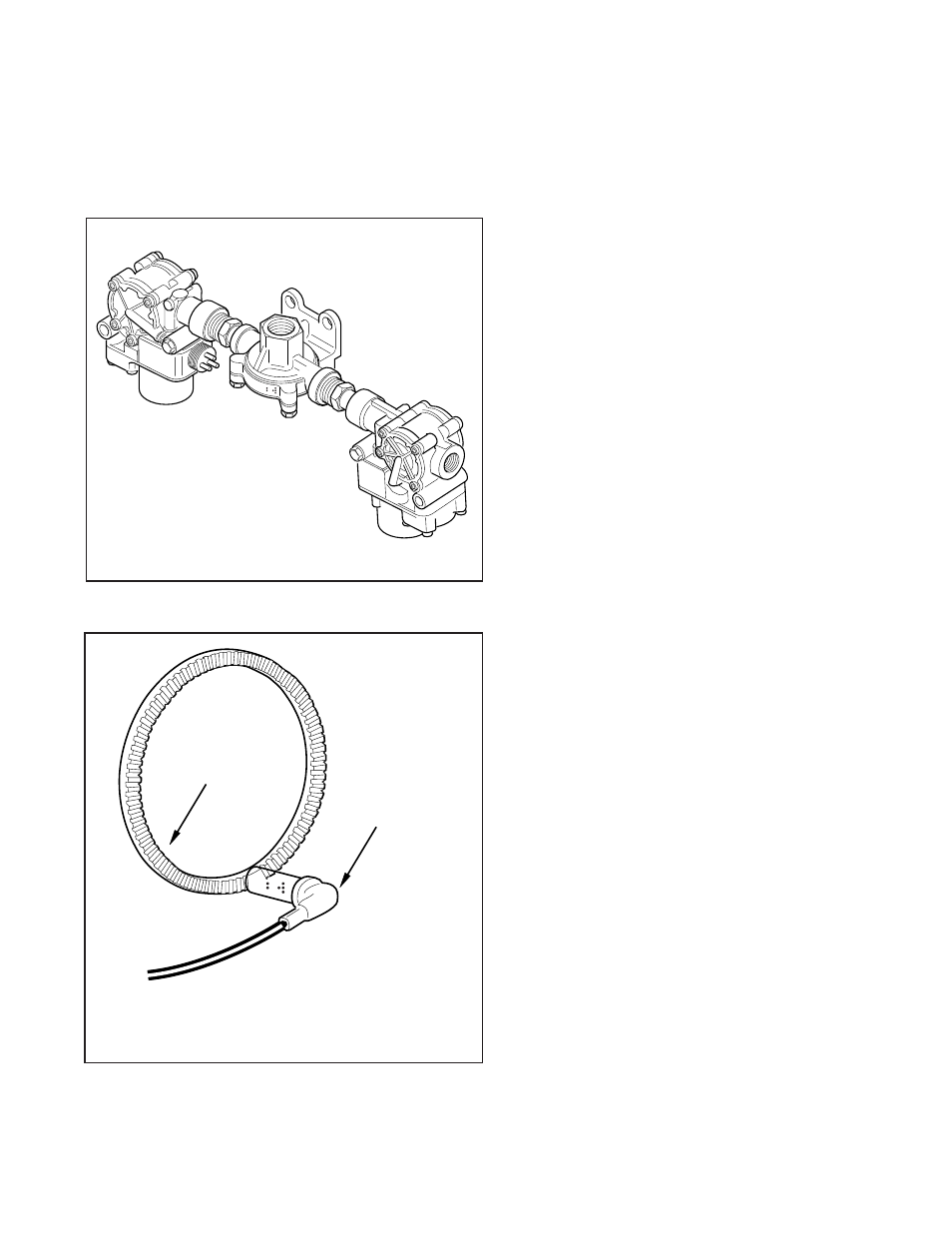

FIGURE 14 - Front Axle Module

Optional Front Axle Modules

An optional front axle module is available. It is an assembly

of two modulator valves and a quick release valve. Three

crack pressure settings are available:

•

0-1 PSIG

•

3-4 PSIG

•

6-8 PSIG.

FIGURE 15 - Sensor Assembly

Tone

Ring

Wheel End

Sensor

Standard

Wheel End Speed Sensor

Drive and Steer Axles

Right angle version shown

Straight version also available

Speed Sensors

Each wheel of an axle under direct ABS control is monitored

by a speed sensor. Speed sensors for drive axles and steer

axles may be different styles and installed in different

locations.

Wheel End Sensors

For most applications, Bendix ABS uses standard wheel

end sensors (see figure 15). The front sensor is accessible

on the inboard side of the steering knuckle. The rear drive

axle sensor is accessible by removing the wheel and drum

assembly.

Wheel-end sensors are conventional, single point, variable

reluctance sensors. These are often referred to as

"magnetic sensors" or "magnetic pickups." These sensors

consist of a rod or pole piece surrounded by a coil of wire.

A magnet is closely coupled to the pole piece and circulates

a magnetic field through the coil. As the teeth of the tone

ring rotate past the pole piece, the resistance (reluctance)

to the magnetic field varies. The variable reluctance causes

variations in the magnetic field which in turn induce a varying

voltage in the coils which are wound around the pole piece.

Some general characteristics of variable reluctance,

magnetic sensors are:

•

The output voltage decreases as the air

gap increases.

•

The output voltage increases with the speed of the teeth

past the pole piece.

•

The output voltage waveform is independent of the

direction of wheel rotation.

Wheel-End Sensors are protected with stainless steel metal

sheaths. They are designed to fit within beryllium-copper

friction sleeves which give them a self-adjustment feature.