Components – Bendix Commercial Vehicle Systems TABS-6 ADVANCED MC SD SHEET User Manual

Page 5

5

5. COMPONENTS

Installations of the TABS‑6 Adv MC module use the

following components:

Internal:

•

Electronic Control Unit (ECU): The ECU monitors

the speed sensor signals, lateral accelerometer sensor

signal and various pressure sensors (and if configured,

external spring deflection sensor) to determine when

ABS and/or TRSP intervention is required. When

needed, the ECU actuates the appropriate pressure

modulator valves to optimize the brake pressure. The

ECU monitors the system to detect and warn the driver

of any malfunctions. Diagnostic Trouble Codes (DTCs)

are stored in the ECU and can be reviewed to diagnose

the TABS‑6 Adv MC module system.

•

Lateral Accelerometer Sensor: The lateral accel‑

erometer sensor senses the lateral movement of the

trailer and sends an electrical signal directly propor‑

tional to the trailer’s lateral acceleration to the ECU.

•

Supply Pressure Sensor: (non‑serviceable, and

located within the module.)

•

Internal Load Sensor:

For air suspension systems, the load sensor port (P42)

must be plumbed to a fixed axle air ride bellows. Note:

the sensor must not be plumbed to a lift axle bellows

since they are not charged when the axle is not

being used. The function of this sensor is to monitor

the pressure and send an electrical signal directly

proportional to the trailer’s axle load to the ECU.

•

Brake Demand Pressure Sensor: This sensor

monitors the trailer service brake pressure being

applied by the driver and sends an electrical signal

directly proportional to the driver’s brake demand to

the ECU.

•

Brake Delivery Pressure Sensors: These sensors

(P21, P22) monitor the trailer service brake pressure

that is being delivered to the wheel ends through, or

by, the TABS‑6 Adv MC module system and sends

electrical signals directly proportional to the delivered

trailer service brake pressure to the ECU.

•

Modulator Relay Valve (MRV): MRVs are integrated

into the module and are controlled electrically by the

ECU to decrease, hold, or allow the full applied brake

pressure into the brake chamber to control the braking

torque at the wheels.

External:

•

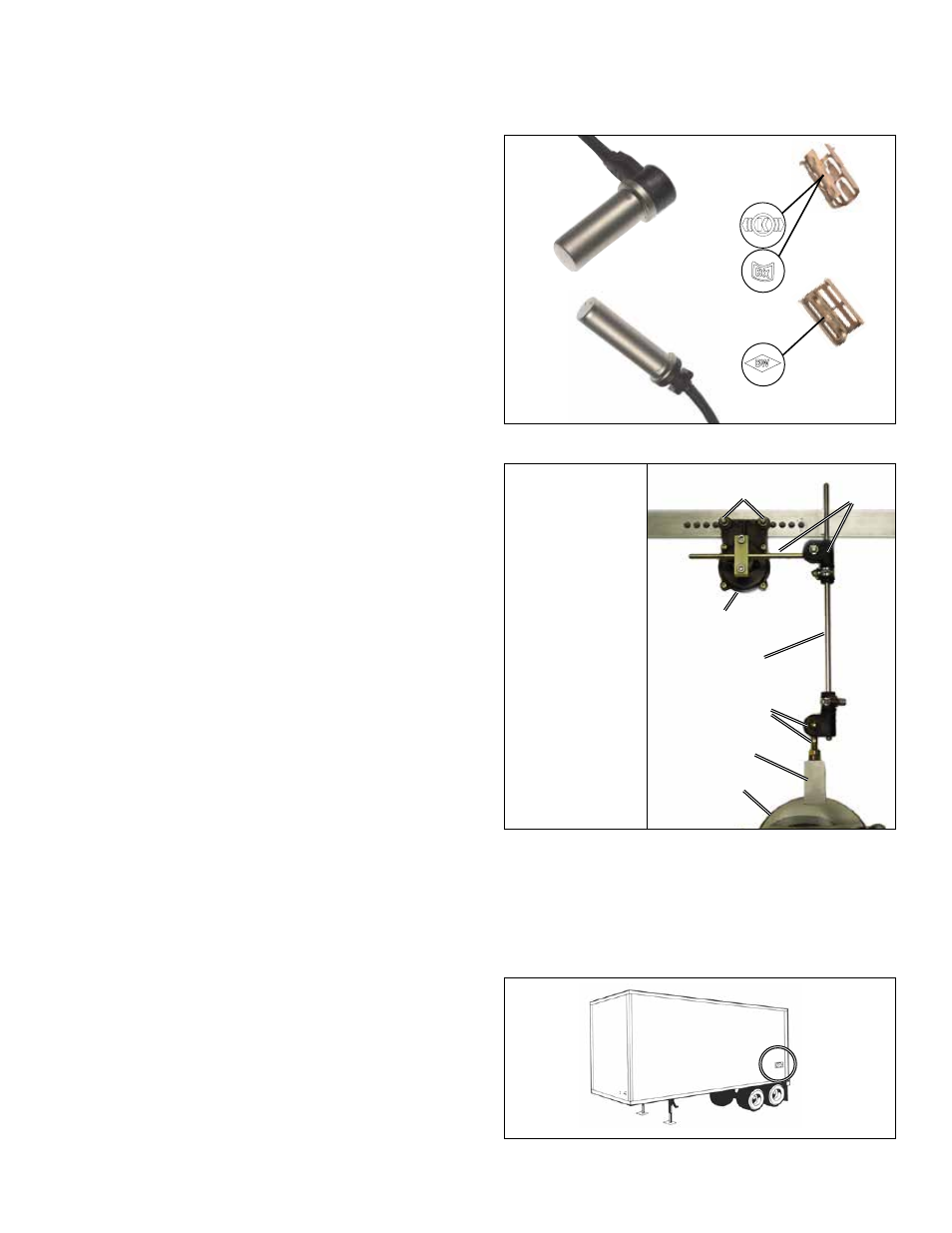

Wheel Speed Sensors (WSS): Located at selected

hubs, wheel speed sensors detect the rotation of indi‑

vidual wheels and send an electrical signal to the ECU

proportional to the rotational velocity. See Figure 3.

•

External Load Sensor:

For spring suspension systems, an

external electrical

spring deflection sensor is installed — typically as close

to the center (±5 inches) as possible of an axle with

linkage attached to the center of the axle (but musT

NoT be installed on a lift axle), see Figure 4. Vehicles

with a mechanical load sensor have the port (P42) used

for sensing the air suspension system plugged.

Note: Do Not Use

Previous WSS

Clamping Sleeves

That Have “BW”

in a Diamond

90° Speed

Sensors

Straight Speed

Sensors

Sensor

Clamping

Sleeve

Acceptable

Logo-Stamped

Sleeves

FIGURE 3 ‑ bendix

®

WS-24

™

Wheel SPeed SenSoRS

Load Sensor

Vertical Linkage Rod

Axle Attachment

Bracket

Axle Strap-Style

Fastener Clamp

Mounting

Bolts

Rubber

Link and

Rod

Adjustable Linkage

with Rubber Link

FIGURE 4

‑ tYPicAl

exteRnAl

loAd SenSoR

inStAllAtion

•

Trailer ABS Indicator Lamp: Controlled by the ECU

to show the ABS status, the trailer ABS indicator lamp

illuminates when a Diagnostic Trouble Code (DTC) is

active. See Figure 5. If there are no ABS diagnostic

trouble codes present, when ignition power is applied

to the ECU, the lamp will illuminate as a bulb check

lasting typically two (2), up to six (6) seconds at most.

FIGURE 5 ‑ tRAileR-mounted AbS indicAtoR lAmP