0 recommended test equipment, 0 push pin heat sink installation, 0 test configurations – Vicor Full-chip PRM-RS Customer Board User Manual

Page 10

UG:009

vicorpower.com

Applications Engineering: 800 927.9474

Page 10

6.0 Recommended Test Equipment

The following is a list of recommended test equipment. Output load current, and voltage ratings are

a function of the VTM

®

module selected (if used).

1. DC Power Supply: 0 – 100 V, 500 W minimum.

a. Set Overvoltage Protection (OVP) based on absolute maximum rating of PRM

®

module.

2. Load: Rated appropriately based on output voltage, current, and power requirements. Electronic

load, 0 to 100 V, 130 A minimum recommended.

3. DMM(s).

4. Oscilloscope + Probe(s).

5. Interconnect cables and fastening hardware.

6. Calibrated input and output shunts, appropriately rated.

7. Trim Pot screwdriver

8. Fan

9. Data sheets for requisite PRM and VTM devices used.

10. Safety glasses.

7.0 Push Pin Heat Sink Installation

Each PRM and VTM Customer Board comes with its own heat sink and push pins for installation.

Before testing, it is highly recommended that heat sinks be installed in the appropriate location for

each board. When installing the push pin heat sink, use caution not to exceed the maximum

compressive on the device listed in the data sheet.

8.0 Test Configurations

The full-chip PRM-RS Customer Board is designed to work in a number of different configurations as

described in the following section. The scope of this document is limited to describing a single PRM

Customer Board as a stand-alone or connected to a single VTM Customer Board. Other

configurations may be possible, though they cannot be guaranteed to have stable operation with the

components designed onto the board. If testing is to be performed outside of the recommended

configurations, the design should be evaluated to determine if changes to any of the onboard

components are necessary.

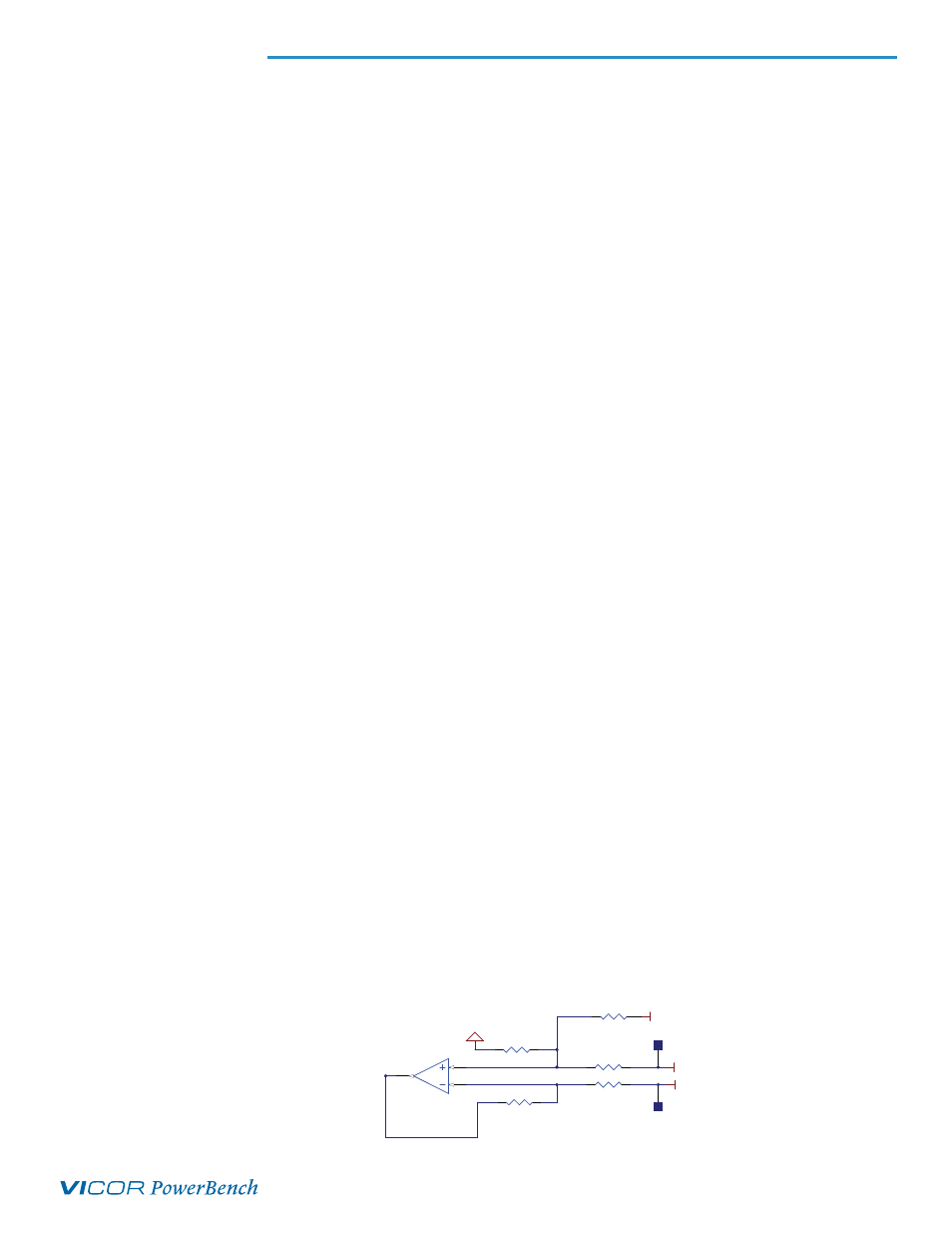

8.1 PRM Board Stand-alone Operation

In this configuration, the PRM module output voltage is sensed through the divider formed by

R40 and R23. U09B is configured as a buffer as illustrated in Figure 9, and provides the sense

voltage to the error amplifier (U09A). R24, and R29 are left open, reserved for differential sensing.

R40 is set to limit the upper trim range based on a maximum reference voltage of 1.25 V.

1.24k

R30

1.24k

R23

V s-

V s+

PRMO UT

V S+

V S-

TP10

TP11

R4 0

R24

R29

6

5

7

U09B

GND

OPEN

OPEN

54.9k

Figure 9: Local Sense

Configuration