For more information – Vicor ComPAC Family 50 to 600 Watt DC-DC Switchers User Manual

Page 7

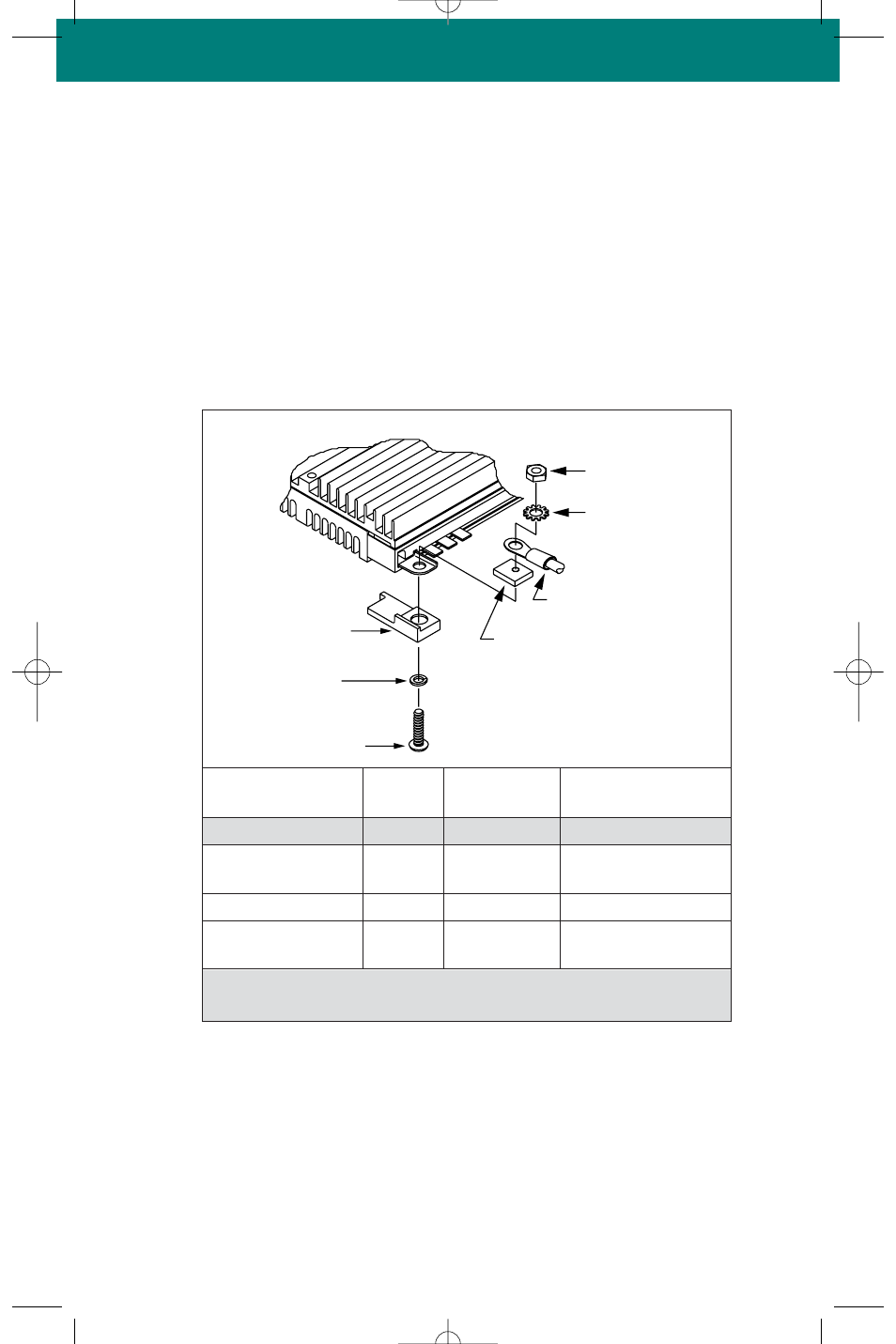

Metal Terminal

Drawing: P.N. 10894 #1

Terminal and

Terminal

Recommended

Product Model

Style

Stud Size

Torque

–Output, +Output

LC-, PC-, &

PCB

8-32 UNC

10 in-lbs (1.1 N-m)

RC-Series

MC- & NC-Series

Metal

10-32 UNC

15 in-lbs (1.7 N-m)

QC-Series

PCB

8-32 UNC

10 in-lbs (1.1 N-m)

Metal

10-32 UNC

15 in-lbs (1.7 N-m)

Supervisory

Sized to accept AMP Faston

®

insulated

All models

receptacle #2-520184-2

EXTERNAL TOOTH

LOCKWASHER

#10 TERMINAL

RETAINING NUT

#10 NUT PLATE

USER OUTPUT

TERMINALS

#10 BRASS STUD

HELICAL

LOCKWASHER

(FITS WITHIN

OPENING PROVIDED)

TERMINAL COVER

NEGATIVE

7

If the unit is operated unmounted, insert a #6 or metric flathead screw

through each hole from below and secure with a nut on top, torqued to 6 in-

lbs (0.7 N-m). A thermal interface material is recommended for –CC models

– consult factory.

Output Terminal Connections. A hardware kit with parts for output terminal

connections is provided with each ComPAC unit. The following drawing

shows the assembly of those parts for the proper connection of metal power

terminals. Assembly for PCB power terminals is the same except that they do

not require an external tooth lockwasher. Consult the table below for the

recommended torque level for each stud size.

“AMP” and “Faston” are registered trademarks of AMP, Incorporated, Harrisburg, PA.

For More Information

The Vicor Applications Manual and product data sheet contain complete

information about ComPAC DC-DC Switchers. To receive literature or to

consult an applications engineer about installation or operation of this product,

contact your nearest Vicor office. (See page 8.)

(Bitte lesen Sie die Sicherheits-Vorschriften auf Seite 8.)