Selection procedure, Example – Thermal Transfer Systems OCA Series User Manual

Page 4

O

CA

www.thermaltransfer.com

262.554.8330

67

A

IR C

O

O

L

E

D

O

CA

Selection Procedure

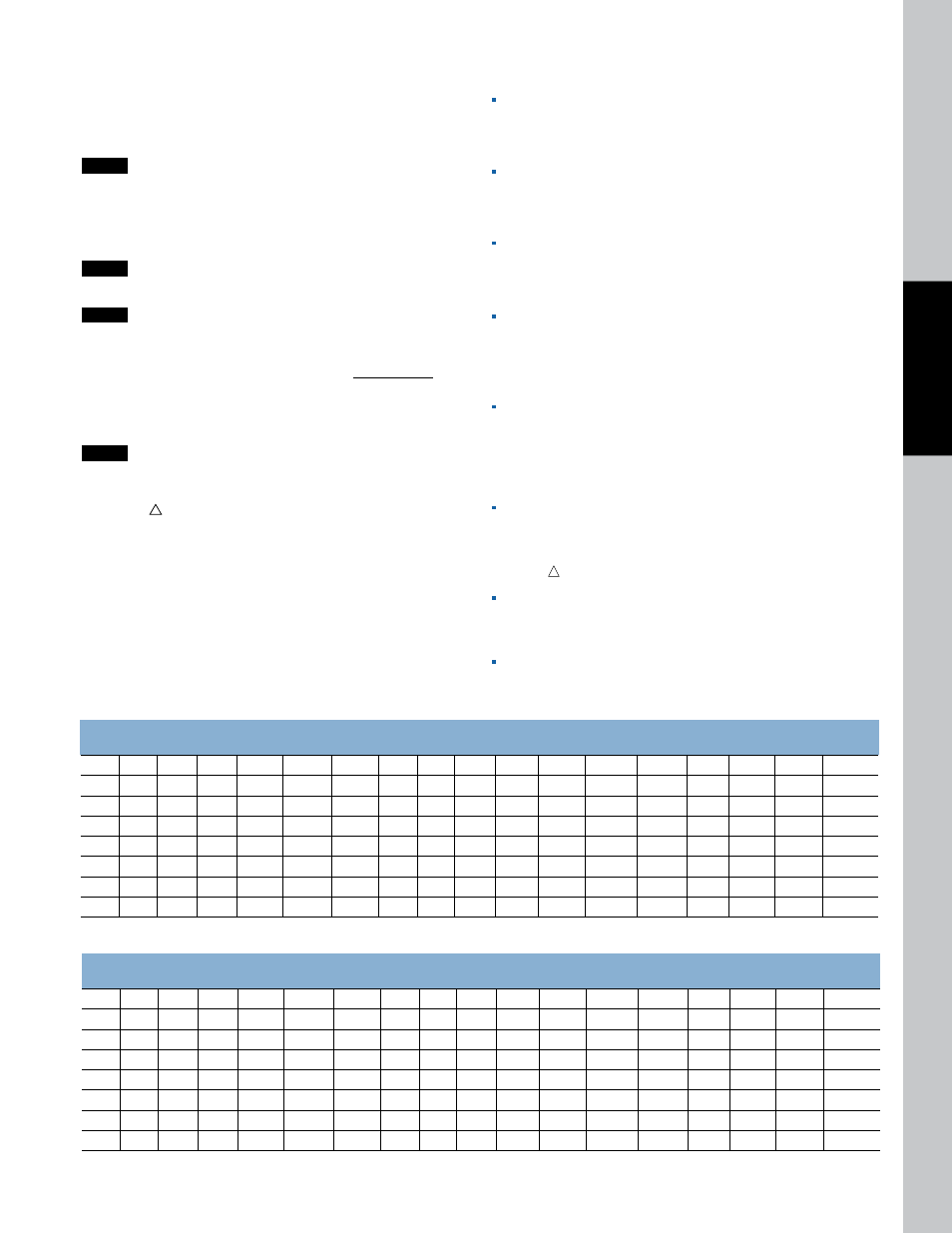

Performance Curves are based on 50SSU oil entering the cooler 100°F higher

than the ambient air temperature used for cooling. This is also referred to as

a 100°F Entering Temperature Difference (ETD).

step 1

determine the Heat load. This will vary with different systems,

but typically coolers are sized to remove 25 to 50% of the input

nameplate horsepower.

(Example: 100 HP Power Unit x .33 = 33 HP Heat load.)

Convert HP to BTU/MIN: HP x 42.41 = BTU/MIN

step 2

determine entering temperature difference (etd).

Desired oil entering cooler °F – Ambient air temp. °F = Actual ETD

step 3

determine Curve Horsepower Heat load.

Enter the information from above:

E.T.D. Temperature Correction Factor:

Btu/Mincorrected = Input Btu/Min x

100 x Cv

Desired E.T.D.

step 4

enter curves at oil flow through cooler and curve horsepower.

Any curve above the intersecting point will work.

step 5

determine oil pressure drop from Curves:

l

= 5 PSI; n = 10 PSI; s = 20 PSI; ; = 30 PSI; H = 50 PSI.

Multiply pressure drop from curve by correction factor found in

oil

P correction curve.

Example

FLUID = SAE 20 OIL

SYSTEM ELECTRIC NAMEPLATE HORSEPOWER = 300HP

ENTERING TEMPERATURE = 200°F

AMBIENT TEMPERATURE = 75°F

FLOW RATE = 200GPM

100

2.04

2.44

4.44

6.44

8.84

1.11

1.57

1.86

2.58

4.23

6.48

9.42

13.60

1.30

3.04

3.54

0.770

110

1.74

2.14

3.64

5.14

6.74

1.08

1.49

1.76

2.39

3.77

5.74

8.37

11.67

1.24

2.44

2.94

0.760

120

1.54

1.84

3.04

4.24

5.64

1.06

1.42

1.64

2.19

3.30

5.95

7.27

9.77

1.18

2.14

2.54

0.749

130

1.44

1.64

2.64

3.44

4.54

1.03

1.34

1.53

1.98

2.84

4.18

6.23

7.84

1.12

1.94

2.24

0.738

140

1.34

1.54

2.27

2.94

3.74

1.01

1.27

1.42

1.79

2.42

3.51

5.24

6.15

1.07

1.94

2.04

0.726

150

1.24

1.34

1.94

2.54

3.14

0.99

1.21

1.34

1.65

2.08

2.94

4.39

4.81

1.02

1.74

1.94

0.716

200

0.97

1.00

1.24

1.44

1.64

0.93

1.03

1.12

1.22

1.37

2.63

1.78

1.99

0.94

1.24

1.34

0.675

250

0.85

0.86

0.96

1.01

1.09

0.89

0.97

1.00

1.07

1.15

1.25

1.26

1.27

0.87

1.04

1.09

0.596

mil-l

ester

sae 5

sae 10

sae 20

sae 30

sae 40

iso 22

iso 32

iso 46

iso 68

iso 100

iso 150

iso 220

iso 320

7808

polyglycol phosphate

50%eg

entering

liquid

temp

C

p

pressure drop CorreCtion FaCtors

100

1.12

1.16

1.26

1.39

1.46

1.09

1.15

1.19

1.27

1.38

1.44

1.57

1.85

1.20

0.93

0.84

0.86

110

1.10

1.13

1.21

1.33

1.41

1.07

1.14

1.17

1.26

1.32

1.40

1.49

1.68

1.15

0.90

0.81

0.85

120

1.07

1.11

1.18

1.28

1.36

1.05

1.12

1.15

1.21

1.28

1.36

1.41

1.54

1.10

0.89

0.80

0.85

130

1.05

1.09

1.14

1.25

1.30

1.04

1.10

1.14

1.18

1.25

1.31

1.35

1.45

1.06

0.86

0.78

0.84

140

1.04

1.06

1.12

1.20

1.26

1.03

1.09

1.11

1.17

1.21

1.27

1.31

1.40

1.04

0.85

0.77

0.83

150

1.02

1.05

1.10

1.17

1.23

1.03

1.07

1.10

1.14

1.18

1.23

1.28

1.34

1.02

0.84

0.75

0.83

200

0.99

1.00

1.02

1.05

1.08

0.99

1.00

1.01

1.02

1.03

1.09

1.10

1.15

0.99

0.80

0.72

0.81

250

0.96

0.97

0.98

0.99

1.00

0.96

0.97

0.97

0.97

0.98

1.00

1.02

1.03

0.98

0.77

0.70

0.80

mil-l

ester

sae 5

sae 10

sae 20

sae 30

sae 40

iso 22

iso 32

iso 46

iso 68

iso 100

iso 150

iso 220

iso 320

7808

polyglycol phosphate

50%eg

entering

liquid

temp

C

V

VisCosity CorreCtion FaCtors

Determine heat load.

Generally, about 25% to 33% of the system horsepower is removed.

300hp x 0.33 = 99hp

Since the graphs have the heat load in terms of BTU/min, the units must

be converted.

99hp x 42.4167 = 4,199 BTU/min

Calculate the entering temperature difference (E.T.D.). The E.T.D. is the

inlet oil temperature minus the entering air temperature.

ETD=200-75 =125

Calculate the corrected curve heat load.

Corrected curve heat load = actual heat load x (100/ETD) x Cv (viscosity

correction factor obtained from the Cv table).

4,199 BTU/min x (100/125) x 1.02= 3,426 BTU/min

Find the intersection point between the corrected heat load and flow rate

on the performance curves. Any curve above this point will work for this

application. Usually the smallest cooler is most desired. In this case the

intersecting point on the single pass graph indicates that the OCA-450

will suffice.

The pressure drop should be found next. Find the point on the curve that is

directly above the intersecting point. This point on the curve indicates the

pressure drop.

P

≈ 6psi

These curves are made for SAE 10 oil entering at 200°F. Therefore,

the pressure drop needs to be corrected. The 1.24 is the pressure drop

correction factor obtained in the Cp table.

P

CORRECTED

= 6 x 1.24= 7.44 psi