Bo l, Performance curves, Bol models with optional t-bar core – Thermal Transfer Systems BOL Series User Manual

Page 5: Oil temperature, Desired reservoir temperature

BO

L

262.554.8330

www.thermaltransfer.com

58

A

IR C

O

O

L

E

D

B

OL

Performance Curves

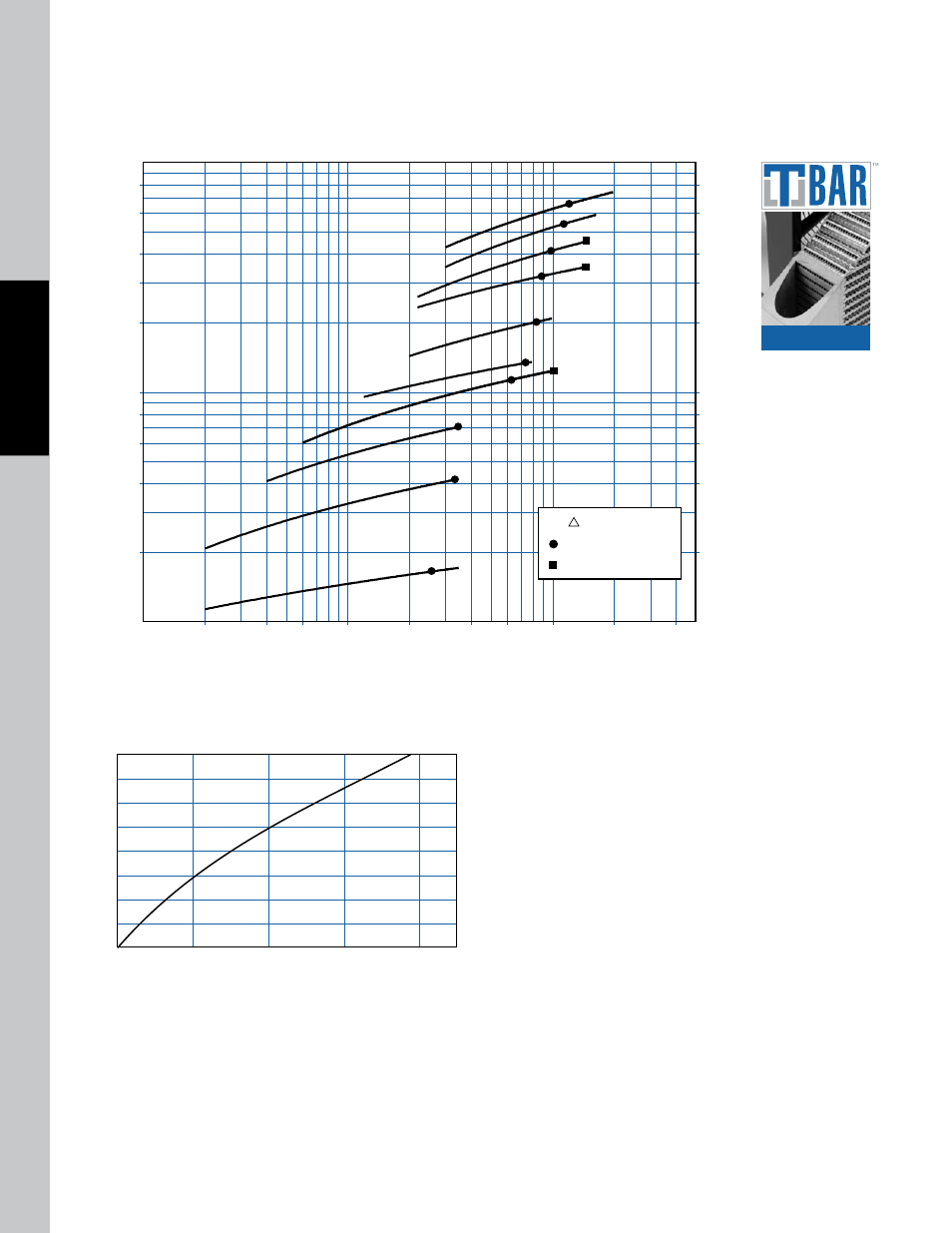

BOL Models with Optional t-BAR Core

BOL-T -Bar Series

BOL-30

BOL-400

BOL-725

BOL-950

BOL-1200

BOL-1600

BOL-16

BOL-8

BOL-4

BOL-2000

= 5 PSI

= 10 PSI

(0.34 BAR)

(0.69 BAR)

Oil P

Oil Flow GPM (LPM)

1

(3.79)

2

(7.57)

20

(75.71)

40

(151.42)

60

(227.12)

100

(378.54)

4

(15.14)

6

(22.71)

10

(37.85)

200

(757.08)

400

(1514.16)

H

ea

t R

ej

ec

tio

n

B

TU

/H

R

@

1

00

F

ET

D

10,000

20,000

40,000

60,000

80,000

100,000

200,000

300,000

400,000

600,000

800,000

1,000,000

0.05

0.1

0.2

0.3

0.4

0.5

1.1

1.6

2.1

3.2

4.2

5.3

H

ea

t R

ej

ec

tio

n

KW

/°

C

OPt IONAL t-BAR CORE

SECt ION CUtAwAy

50 150 250 350

450

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

Viscosity (SSU)

Co

rr

ec

tio

n

Fa

ct

or

Pressure Drop

Oil temperature

Typical operating temperature ranges are:

Hydraulic Motor Oil

120°F - 180°F (49°C - 82.2°C)

Hydrostatic Drive Oil

160°F - 180°F (71°C - 82.2°C)

Engine Lube Oil

180°F - 200°F (82.2°C - 93.3°C)

Automatic Transmission Fluid

200°F - 300°F (93.3°C - 149°C)

Desired Reservoir temperature

oil temperature: Oil coolers can be selected using entering or leaving oil

temperatures.

off-line recirculation Cooling loop: Desired reservoir temperature is the

oil temperature entering the cooler.

return line Cooling: Desired reservoir temperature is the oil temperature

leaving the cooler. In this case, the oil temperature change must be

determined so that the actual oil entering temperature can be found.

Calculate the oil temperature change (oil

#

T) with this formula:

Oil

#

T = (BTU’s/Hr.) / (GPM Oil Flow x 210).

To calculate the oil entering temperature to the cooler, use this formula:

Oil Entering Temp. = Oil Leaving Temp + Oil

#

T.

oil pressure drop: Most systems can tolerate a pressure drop through the

heat exchanger of 20 to 30 PSI. Excessive pressure drop should be avoided.

Care should be taken to limit pressure drop to 5 PSI or less for case drain

applications where high back pressure may damage the pump shaft seals.

Note: Derate heat

rejection values 15%

if using 50Hz motors.

performance data Curve