Dimensions, Selection procedure, Four pass – Thermal Transfer Systems EC Series User Manual

Page 3: Oil temperature

EC

262.554.8330

www.thermaltransfer.com

86

W

A

T

E

R C

O

O

L

E

D

EC

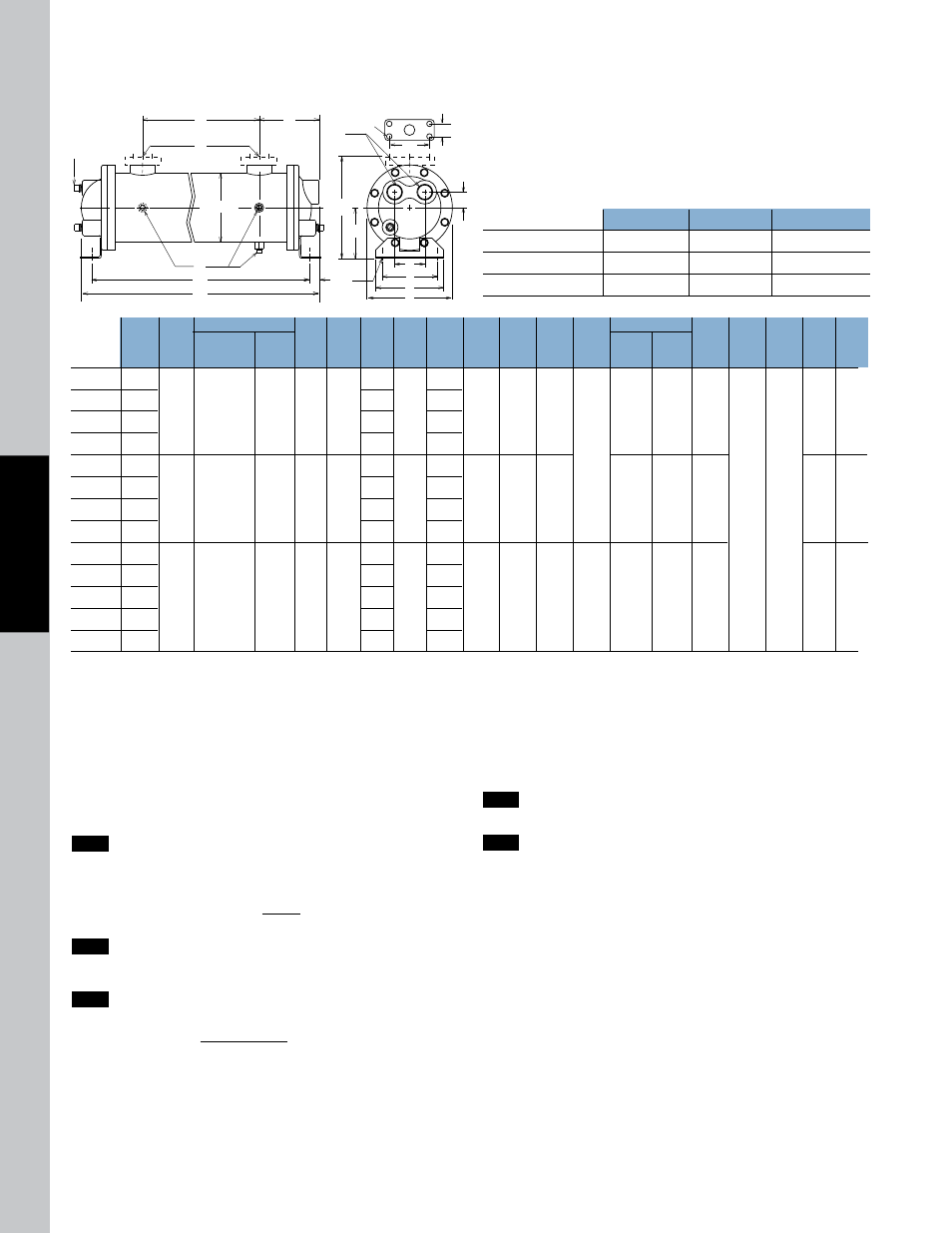

Dimensions

SAe Flange Size

X

Y

Z

1-1/2

1.41

2.75

1/2 - 13

2

1.69

3.06

UNC-2B

3

2.44

4.19

5/8 - 11 UNC 2B

F

G

N

E

H

M

T

K

L

B

C

P

D

U

J

A

Z (4 places)

Y

X

R

S

NOTE: We reserve the right to make reasonable design changes without notice. All dimensions are in inches.

MODEL

A

B

NPT

BSPP

SAE O-RING

SAE

FLANGE

NPT

BSPP

FLANGE

SAE

O-RING

NPT

BSPP

C

D

E

F

G

H

J

K

L

M

U

T

N

P

NPT

BSPP

R

NPT

BSPP

S

EC-1014

EC-1024

EC-1036

EC-1054

EC-1224

EC-1236

EC-1254

EC-1272

EC-1724

EC-1736

EC-1754

EC-1772

EC-1784

19.87

29.87

41.87

59.87

29.78

41.78

59.78

77.78

31.61

43.61

61.61

79.61

91.61

10.12

20.12

32.12

50.12

18.97

30.97

48.97

66.97

18.75

30.75

48.75

66.75

78.75

18.38

28.38

40.38

58.38

27.84

39.84

57.84

75.84

29.25

41.25

59.25

77.25

89.25

6.75

DIA.

7.75

DIA.

10.50

DIA.

5.25

DIA.

6.25

DIA.

8.50

DIA.

7.75

8.75

11.50

8.00

9.38

12.50

4.00

4.50

5.75

4.82

5.44

7.06

.75

1.00

1.81

4.00

5.00

7.00

5.25

6.25

8.25

.50

x

.75

SLOT

.62

x

.88

SLOT

1

1

/

2

2

3

#24

SAE

#32

SAE

N/A

1

1

1

/

2

2

(3)

3/8

(3)

3/8

2.40

2.82

4.25

1.20

1.41

1.41

Four Pass

NOTE: We reserve the right to make reasonable design changes without notice. All dimensions are in inches.

Selection Procedure

Performance Curves are based on 100SSU oil leaving the cooler 40°F

higher than the incoming water temperature (40°F approach temperature).

Step 1

Determine the Heat load. This will vary with different systems,

but typically coolers are sized to remove 25 to 50% of the input

nameplate horsepower. (Example: 100 HP Power Unit x .33 = 33

HP Heat load.)

If BTU/Hr. is known: HP = BTU/Hr

2545

Step 2

Determine Approach Temperature.

Desired oil leaving cooler °F – Water Inlet temp. °F = Actual

Approach

Step 3

Determine Curve Horsepower Heat load. Enter the

information from above:

HP heat load x 40 x Viscosity = Curve

Actual Approach Correction A Horsepower

Step 4

enter curves at oil flow through cooler and curve horsepower.

Any curve above the intersecting point will work.

Step 5

Determine Oil Pressure Drop from Curves. Multiply pressure

drop from curve by correction factor B found on oil viscosity

correction curve.

l

= 5 PSI; n = 10 PSI; s = 20 PSI.

Oil Temperature

Oil coolers can be selected by using entering or leaving oil tempertures.

Typical operating temperature ranges are:

Hydraulic Motor Oil

110°F - 130°F

Hydrostatic Drive Oil

130°F - 180°F

Lube Oil Circuits

110°F - 130°F

Automatic Transmission Fluid

200°F - 300°F