Bryant 548F User Manual

Page 20

—

20

—

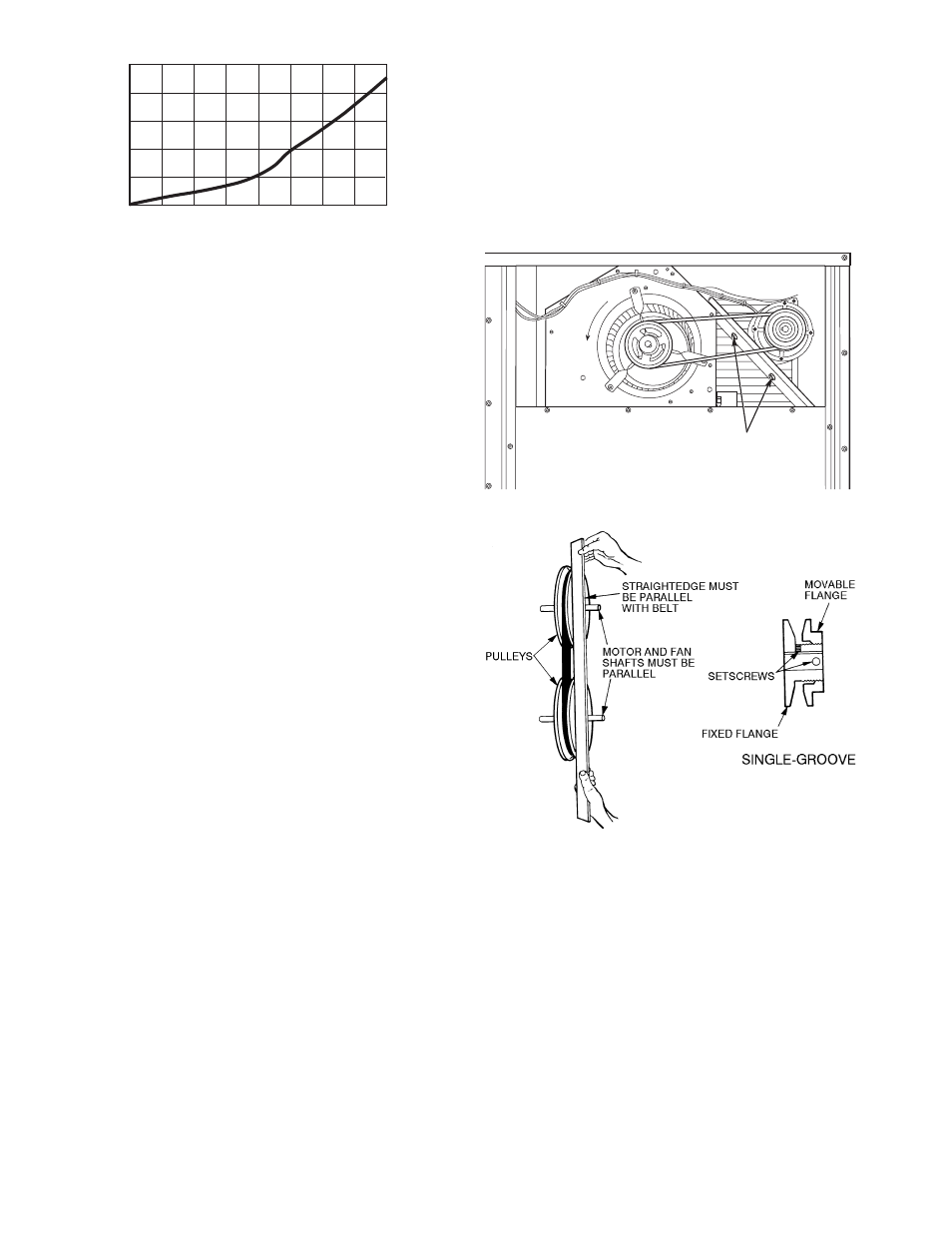

VII. STEP 7 — ADJUST INDOOR-FAN SPEED

Adjust indoor-fan rpm to meet jobsite conditions. See Table 5

for fan rpm at motor pulley settings. See Table 6 for motor

performance data. See Table 7 for static pressure drops.

Refer to Tables 8-29 to determine fan speed settings.

For units with electric heating, required minimum cfm is 900

for 548F036; 1200 for 548F048; 1500 for 5548F060 and 1800

for 548F072.

A. Direct Drive Motors

The indoor-fan motor factory speed setting is shown on label

diagram affixed to base unit. If other than factory setting is

desired, refer to label located on motor for motor reconnec-

tion. Insert wire into the speed tap corresponding to desired

speed.

B. Belt-Drive Motors

Fan motor pulleys are factory-set for speed shown in Table 1.

See Fig. 33.

To change fan rpm:

1. Shut off unit power supply. Install lockout tag.

2. Loosen belt by loosening fan motor mounting nuts.

3. Loosen movable pulley flange setscrew (see Fig. 34).

4. Screw movable flange toward fixed flange to increase

fan rpm and away from fixed flange to decrease fan

rpm. Increasing fan rpm increases load on motor. Do

not exceed maximum speed specified in Table 1.

5. Set movable flange at nearest flat edge of pulley hub

and tighten setscrew. (See Table 1 for speed change

for each full turn of pulley flange.)

To align fan and motor pulleys:

1. Loosen fan pulley setscrews.

2. Slide fan pulley along fan shaft.

3. Make angular alignment by loosening motor from

mounting.

To adjust belt tension:

1. Loosen fan motor mounting nuts.

2. Slide motor mounting plate away from fan scroll for

proper belt tension (

1

/

2

-in. deflection with 5 to 10 lbs

of force).

3. Tighten nuts.

4. Re-check pulley alignment.

0

200

400

600

800

1000 1200 1400 1600

FLOW (CUBIC FEET/MINUTE)

0.5

0.4

0.3

0.2

0.1

0

ST

A

TIC PRESSURE (IN. WG)

Fig. 32 — Barometric Relief Capacity

MOTOR MOUNTING

NUTS AND BOLTS

Fig. 33 — Belt-Drive Motor Mounting

Fig. 34 — Indoor-Fan Pulley Adjustment