S&S Cycle Super E and G Series Shorty Carburetors User Manual

Page 25

25

•

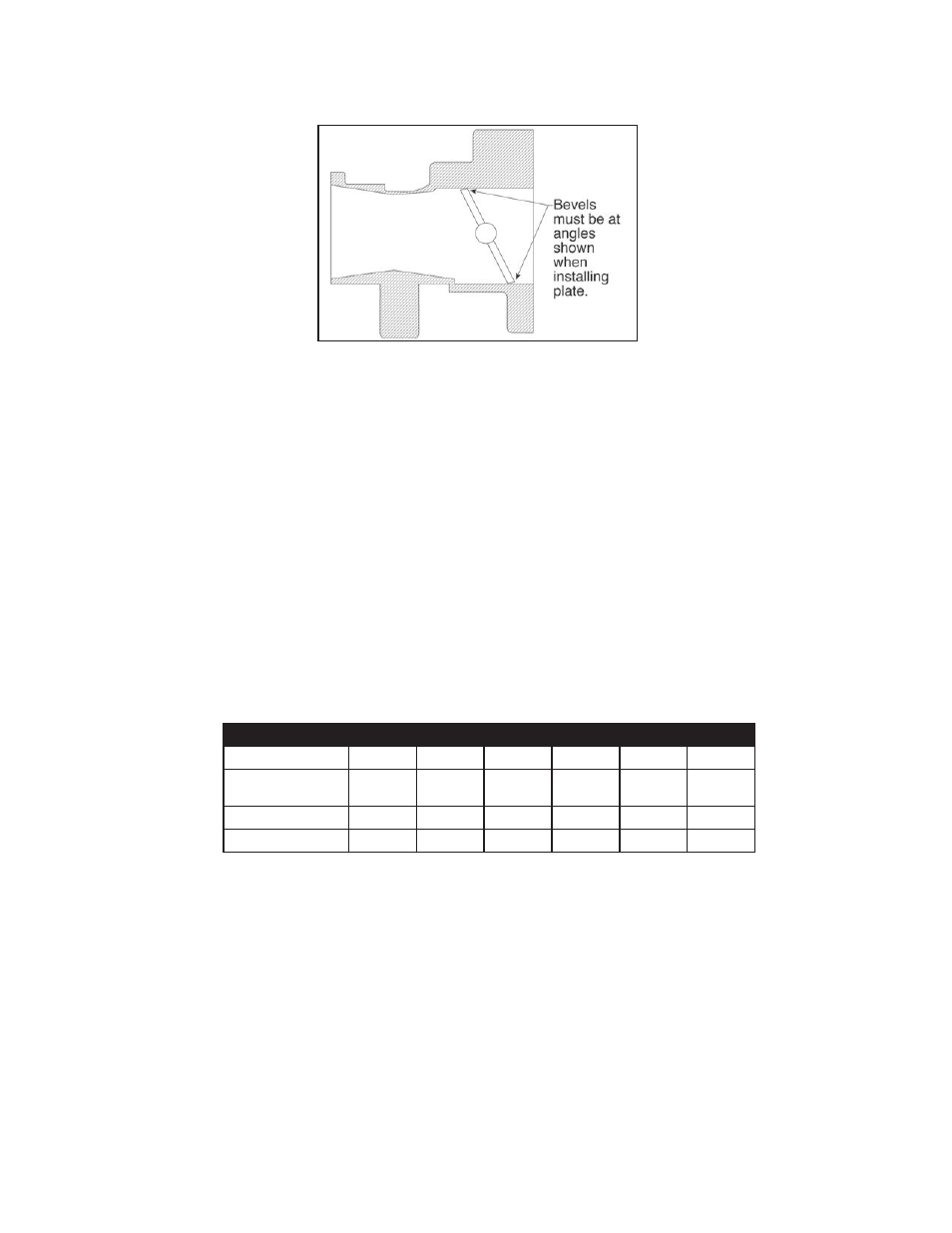

Throttle plate and throttle shaft should be checked annually for signs of wear. Replace if necessary. If carb body throttle shaft bushings are worn, carb

must be returned to S&S® for repair. If throttle plate removed, be sure to reinstall correctly. See Figure C. Beveled edges of plate must fit flat against carb

throat.

•

If accelerator pump cap is removed, lift cap slowly so small spring checkballs and o-rings are not lost.

•

For racing, S&S offers two air horn conversion kits which include appropriate mounting hardware and a substitute enrichment device. One includes a 21⁄2"

air horn and the other includes a 4" air horn.

•

If fuel delivery from stock petcock appears insufficient, S&S recommends that a high flow performance petcock be installed.

IMPORTANT NOTES:

•

We at S&S feel we have designed and manufactured a superior product and will stand behind it. If you have questions or problems, first refer to this

instruction manual. Answers to nearly all questions can be found herein. If your problem cannot be resolved, call 608-627-8324 for technical assistance.

Do not, however, call until you have become thoroughly familiar with this manual.

•

S&S also has a complete carburetor repair and rebuild service that provides quality work at a fair price. If you are not properly equipped to service an S&S

carburetor and do not have a qualified repair shop nearby, we recommend that you contact us for a Return Authorization (RA) number and send the

carburetor to us. Be sure to include a note with your name and address, RA number, and a detailed description of any problems or repairs needed. Thanks

for using S&S products!

Figure C

S&S® SUPER E & G JETTING

Displacement

Stockers

88ci

96ci

100ci

107ci

113ci

Idle Mixture Screw 1 to 11⁄2

Turns

1 to 11⁄2

Turns

1 to 11⁄2

Turns

1 to 11⁄2

Turns

1 to 11⁄2

Turns

1 to 11⁄2

Turns

Intermediate Jet

0.028

0.0295

0.031

0.031

0.031

0.031

Main Jet

0.066

0.072

0.076

0.076

0.076

0.078