S&S Cycle Super E and G Series Shorty Carburetors User Manual

Page 11

11

CAUTION

6- Install Air Cleaner Backplate

NOTE: Air cleaner backplate screws supplied with kit have thread locking compound on threads. If screw without thread locking compound is used, a

thread locking product such as Loctite® 242 must be applied, and screws properly tightened.

Failure to apply thread locking compound or properly tighten screws may cause screws to loosen and fall into engine, causing engine

damage not covered under warranty.

A- All big twin & Sportster® models 1966 to 1982

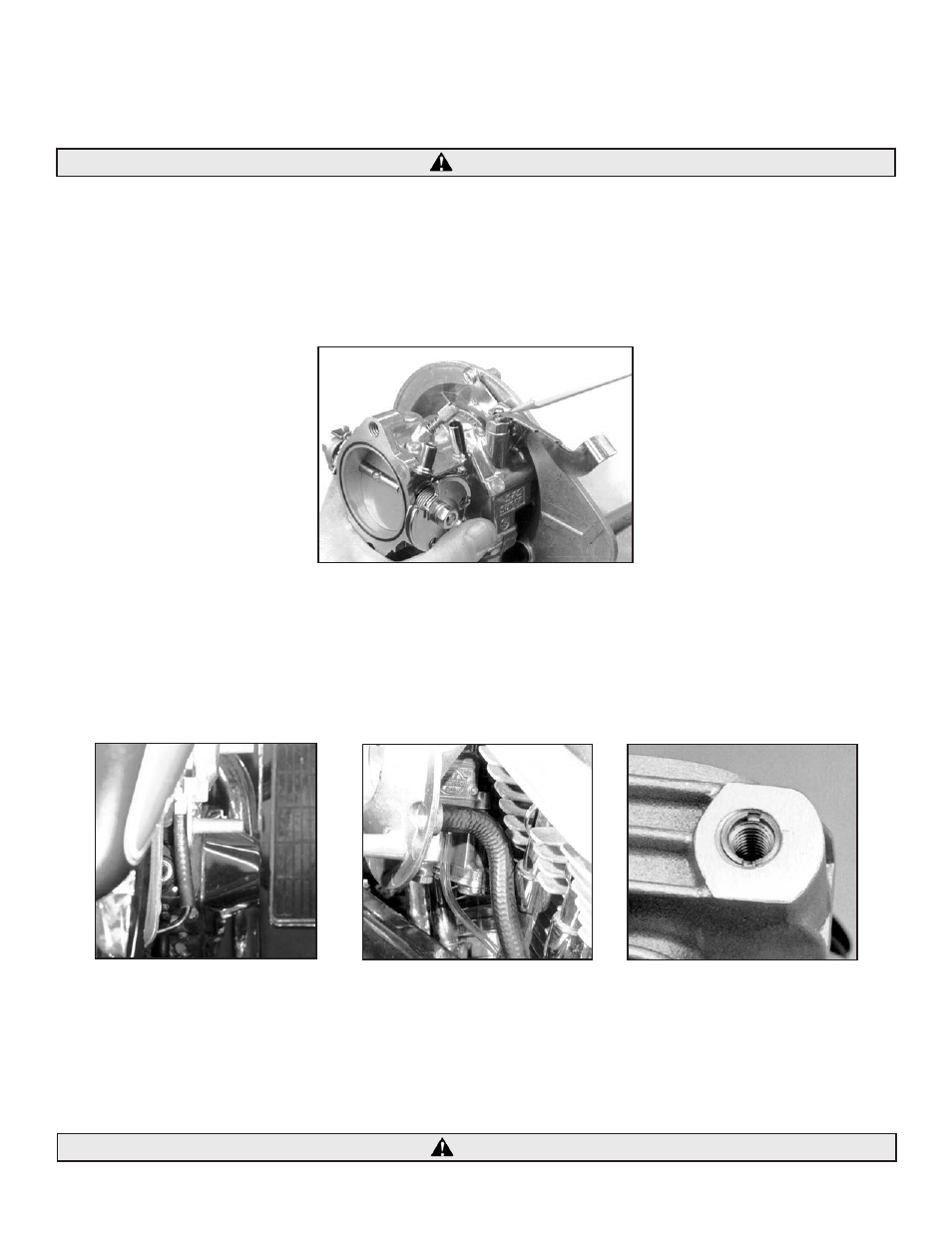

1- Mount air cleaner backplate on carb using three 1⁄4"-20 x 9⁄16" screw/washer assemblies. Confirm that enrichment device lever, engages

enrichment device plunger. See Picture 20. Tighten backplate mounting screws to 5-7 ft-lbs (60-84 in-lbs).

2- Bolt carb mounting bracket to air cleaner backplate. Head of 5⁄16"-18 x 1" bolt should rest in hex recess on inside of backplate with

threaded portion extending through backplate, two 1⁄8" shims and bracket. Secure with 5⁄16" flatwasher and locknut provided.

3- Final tighten of all mounting bracket bolts and manifold clamps.

4- 1980-’84 big twin & Harley-Davidson® Sportster® models 1980 to 1985 - Connect crankcase breather hose to air cleaner backplate hose

fitting. See Pictures 21 and 22.

B- Evolution® big twin 1984 to 1992 and Sportster models 1986 to 1990

1- 1992 big twin models with crankcase breather vented from cases to air cleaner backplate - Install thread-sert in each cylinder head air

cleaner mounting bolt hole. This converts stock 1⁄2"-13 thread to 5⁄16"-18 thread. Surface of thread-sert should be just below surface of

cylinder head. See Picture 23.

NOTES:

•

Most 1992 big twins have crankcase breather routed from case to air cleaner backplate. However, some late 1992 engines have breather routed from

heads to air cleaner backplate through air cleaner mounting bosses. If crankcase breather is routed through heads, 1993 and later carb kit must be

installed. Follow instructions for installation on 1993 engine.

•

Thread-serts may be supplied with or without thread locking compound on threads. Loctite® 242 or equivalent should be applied to threads of thread-

serts not supplied with thread locking compound. Thread-serts should be installed in desired position and left in place.

•

Installing thread-sert in hole activates thread locking compound making it difficult to change position of thread-sert after installation.

Cylinder head vent passages in "head breather" type engine must not be plugged as oil leakage and engine damage may result. Same

applies to crankcase vent in "case breather" type engine.

Picture 21

Picture 22

Picture 23

Picture 20

CAUTION