S&S Cycle Super E and G Series Shorty Carburetors User Manual

Page 20

20

Intermediate Jetting Procedure:

1- Ride motorcycle several miles to bring engine up to normal operating temperature.

2- Check idle mixture adjustment to be sure setting is correct with fully hot engine.

3- Check throttling characteristics by slowly rolling throttle on from a steady speed. This should be done at rpm levels of approximately

2000, 2500, and 3000 rpm. (Depending upon gearing, vehicle speeds will usually be between 30 and 60 MPH). "Popping" or "spitting"

(backfiring) in air cleaner indicates lean condition requiring that intermediate jet be changed to next larger size (size is stamped on end

or side of jet).

4- Change jet accordingly, adjust mixture screw and repeat road test. Smallest intermediate jet that eliminates this condition should

provide best gas mileage.

INTERMEDIATE SYSTEM NOTES:

•

It is helpful to shut off accelerator pump while fine tuning intermediate circuit as fuel supplied by pump can mask jetting symptoms. Consult "Accelerator

Pump" section of instructions.

•

Whenever intermediate jet is changed, idle mixture screw must be readjusted.

•

Elevation changes: A simple readjustment of idle mixture screw will often compensate for changes in elevation of several thousand feet. S&S test riders

have ridden through changes upwards of 7000 feet without changing jets. In other cases, and depending upon accuracy of initial jetting, a change in

intermediate and/or main jet may be required.

•

Higher elevation makes engine run richer, meaning that smaller jets may be required to correct overly rich condition. Lower elevation, nearer sea level,

makes engine leaner so larger jets may be required. While rich condition can cause fouled spark plugs and poor performance, lean condition can result in

engine damage. If smaller jets are installed for higher elevation, remember to install larger jets for operation at lower elevation.

•

Intermediate jet provides majority of fuel under average operating conditions. While it is tempting to change main jet because it is more accessible, in

most cases intermediate jet should be changed to properly address elevation/altitude-related problem.

D- Adjusting High Speed Circuit or Main Jet - High speed circuit begins around 2500-3000 rpm or 55-60 mph under steady speed conditions,

and operates to maximum attainable speed. High speed circuit will be pulled in at much lower rpm if throttle is cracked open. Main jet

size is best determined by testing at drag strip or dynamometer because maximum miles per hour, rpm and horsepower are most reliable

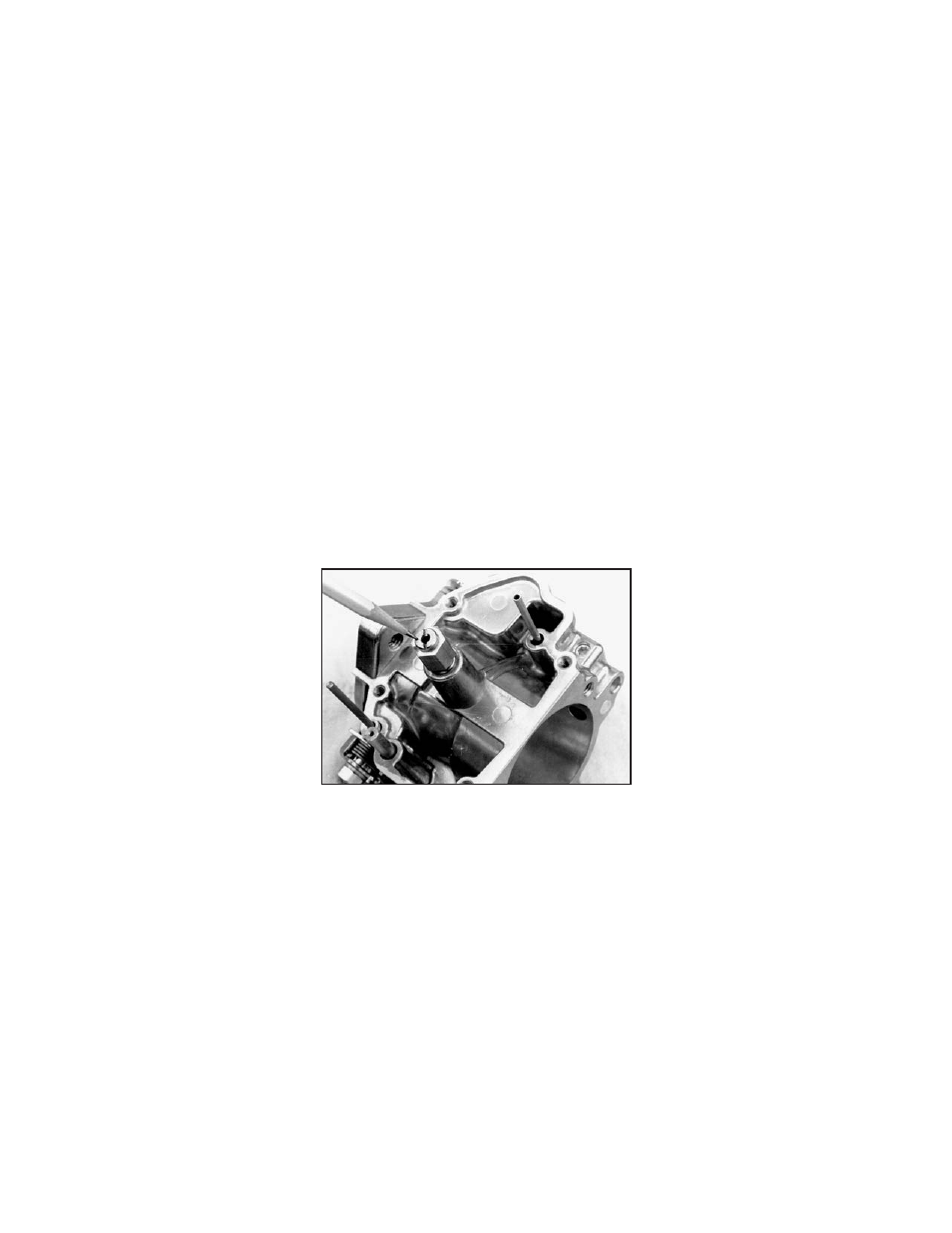

indicators of correct jetting. Main jet (See Picture 43), is reached by removing bowl plug. (See Jetting Chart Page 23).

High Speed (Main) Jetting Procedure:

1- Drag strip/dynamometer procedure

a- Sufficiently warm engine to begin testing.

b- Make run noting engine rpm and final speed or horsepower.

c- Richen main jet by increasing jet size .004" and make second run. Again, note rpm and final speed or horsepower.

d- Continue procedure until mph/horsepower falls off.

e- Decrease or lean main jet size by .002" to gain best rpm and mph. When making runs on drag strip, strive for consistent miles per

hour, not lowest ET.

2- Street Procedure - S&S uses "rpm" method to determine main jet size. Under racing conditions this level is where horsepower peaks

and begins to taper off and is where gear shifts occur. Main jet that makes engine accelerate strongest or rpm through gears quickest

is correct.

NOTE: Placing engine under load by accelerating uphill may make result of jet change more pronounced and easier to interpret.

a- Warm engine to operating temperature.

b- Accelerate rapidly through gears noting how quickly and smoothly engine reaches rpm level where pull of engine begins to fade

and gear shift occurs.

c- If engine backfires in carburetor and sputters or "breaks up"and/or dies during acceleration, increase or richen main jet size .004"

larger and road test again. Note engine smoothness and how easily engine reaches rpm where gear shift occurs.

Picture 43