S&S Cycle Super E and G Series Shorty Carburetors User Manual

Page 18

18

9- If engine was running properly before installation of carburetor, no other changes were made and carb settings were confirmed as

instructed previously, hard starting is likely caused by incorrect intermediate jet or starting routine. Remain calm and patient while

attempting to start motorcycle, and experiment with different starting procedures (throttle and enrichener position, number of squirts

from accelerator pump, etc.), especially with kickstart motorcycle. Carb tuning and ignition tuning and maintenance are critical for kick

start motorcycles.

If severe flooding is suspected, turn ignition off, slowly roll throttle to wide open position, and kick 6-8 times to clear engine. Then close

throttle to approximately 1⁄8 turn, turn ignition on and kick until engine starts.

If insufficient fuel is suspected, remove air cleaner cover and confirm accelerator pump operation, with motor off, by snapping throttle

open from closed position. Fuel should exit accelerator pump nozzle directly behind main discharge tube in carburetor bore.

If not, increase accelerator pump setting by turning adjustment screw out, in counterclockwise direction. Replace air cleaner cover and

attempt to start motorcycle according to procedure previously described.

If more than 2-3 squirts from accelerator pump are required to start motorcycle with temperature 60° or above, larger intermediate

jet may be required. This may also be caused by incorrect idle mixture adjustment or a manifold leak. Refer to following sections for

additional information on tuning.

2- Adjusting Carburetor

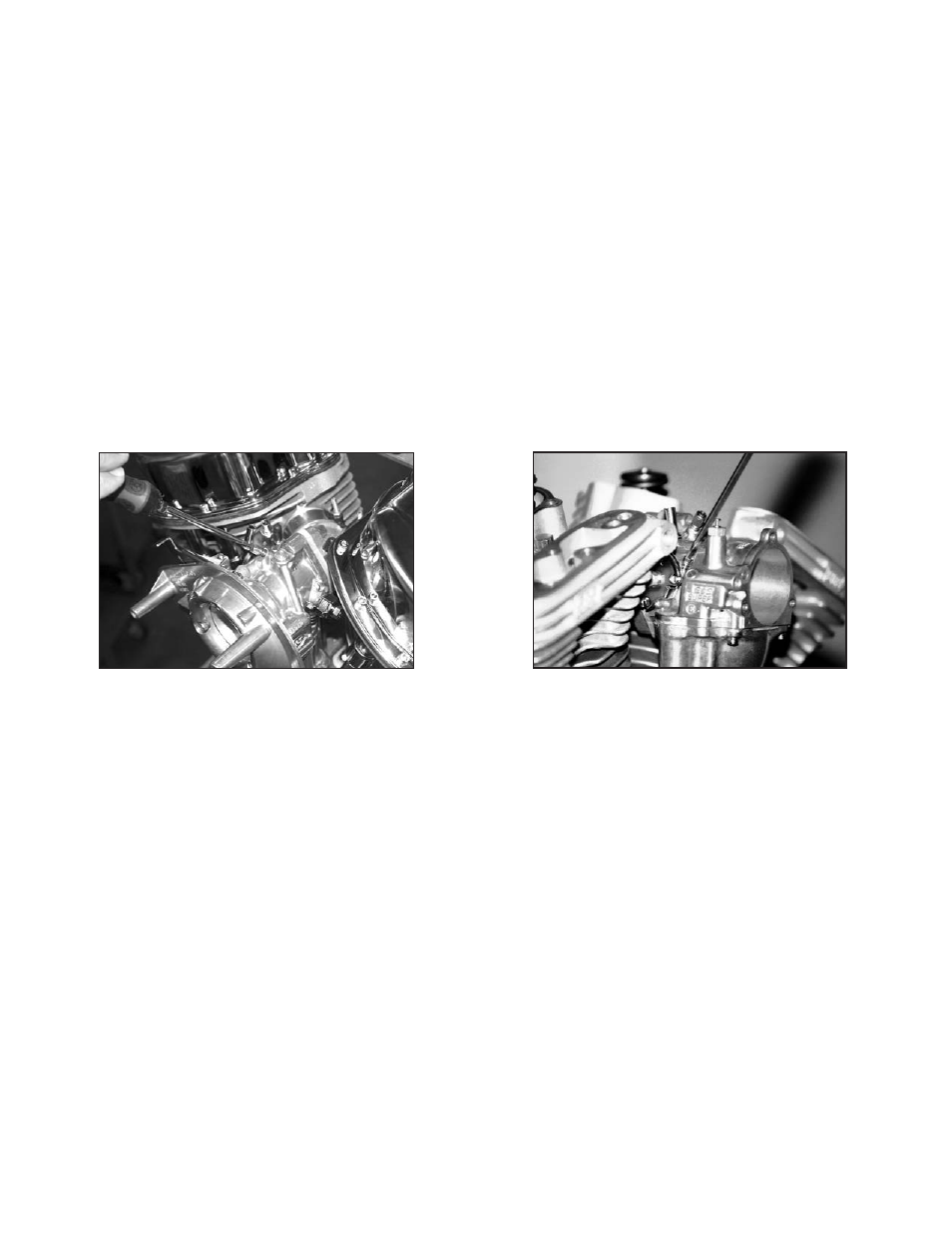

A- Adjusting Idle Circuit - Idle mixture screw regulates air/fuel mixture at idle speeds and has been angled forward for greater accessibility.

See Picture 39, below left. Throttle stop/engine rpm adjustment screw is located on boss on rear side of carburetor body. See Picture 40,

below right. During assembly S&S® adjusts both screws to settings that should work for first start-up after installation.

1- Start engine and run until slightly warm (approximately 1 to 2 minutes).

2- Turn RPM adjustment screw to obtain idle of approximately 1000 RPM.

3- Turn idle mixture screw clockwise, slowly leaning mixture until engine starts to die. Next, turn screw counterclockwise, slowly richening

mixture, until engine RPM fall off. Mixture adjustment is correct when screw is positioned about halfway between these points, or

approximately 1⁄4 to 1⁄2 turn out from lean side of adjustment range.

NOTE: Turning screw out (counterclockwise) makes idle mixture richer. Turning screw in (clockwise) makes mixture leaner. Normally, correctly adjusted

screw will be between 11⁄4 and 3⁄4 turns out from bottom if intermediate jet size is correct. Note that mixture screw must be adjusted according to Step 3

above. Do not leave screw at initial 11⁄2 turn setting without fine tuning.

4- After initial idle mixture adjustment, reset engine idle to approximately 1000 RPM. Lower idle speed can cause hard starting, poor

throttle response, erratic idle and unnecessary engine wear.

5- After engine has reached normal operating temperature, repeat Steps 3 and 4.

IDLE CIRCUIT NOTES:

•

If idle adjustments are made before engine is fully warmed, idle mixture will be rich when engine reaches operating temperature. This is especially true

for engines with aluminum cylinders such as Harley-Davidson® Evolution® and Twin Cam 88®. If ambient temperature is below 60 degrees, engine may

require 10-15 minutes of normal riding to reach operating temperature.

•

Whenever intermediate jet change is made, idle mixture screw must be readjusted.

•

If the idle mixture screw is more than 13⁄4 turns out after idle mixture is correctly adjusted, it is a fairly good indication that the intermediate jet may be

too small and should be changed to the next larger size. If the idle mixture screw ends up less than 11⁄4 turn out, the intermediate jet may need to be

changed to the next smaller size. Be aware that idle mixture screw adjustment can be effected by other factors, but can quite often indicate rich or lean

intermediate jetting.

•

If idle mixture screw is turned completely in, engine should not run at idle. If engine continues to run at idle with idle mixture screw seated, recheck initial

setting of idle speed screw, and make sure enrichment plunger is seated.

Picture 39

Picture 40