S&S Cycle Super E and G Series Shorty Carburetors User Manual

Page 23

23

NOTES:

•

The standard .040" diameter air bleed is the optimum size for most engine combinations, and should not be changed under most circumstances,

regardless of intermediate and main jet selections.

•

Changing the main air bleed size should be done only after determining a mid range driveability problem cannot be corrected by changing the

intermediate and main jets.

•

For tuning the main air bleed, S&S® recommends an initial increase from the standard .040" jet to an .048" jet as a starting point. Available jets and part

numbers are listed in the S&S catalog.

•

It is never necessary to reduce the size of the main air bleed below .040".

•

Shifting the start of main jet operation to a point higher up the rpm scale can lessen the effects of mid rpm driveability problems caused by mismatched

cam and exhaust systems, but will not allow the engine to perform as well as it would with a well designed exhaust system.

INTERMEDIATE AND HIGH SPEED NOTES:

•

Carburetor jetting and spark plug color - While spark plug color may be used to help determine carburetor jetting, S&S recommends that our instructions

be used as primary jetting guide and that plug color indications be used as secondary aid. Different brands of gasoline, gasoline additives, engine heat,

type of plugs, and spark plug heat range can effect plug color making plug reading difficult for average tuner. Also, new plugs usually require road test of

10 miles or more to properly develop color. This means that quarter mile tests may not be long enough to be a good indication of carb jetting. It is best to

use recommended spark plug type and to consult spark plug manufacturer with questions.

•

If bike is used exclusively on drag strip where engine temperatures vary, slightly richer jets may be necessary to obtain best performance. Larger jets and

richer mixtures will enable one to run colder engine which is sometimes desirable. This is best determined by experimentation.

•

Cams and exhaust systems can make some engines difficult to carburate. S&S has found that certain cams and exhaust systems cause poor performance

at a specific rpm, and attempts to correct problem with carb tuning usually degrade carburation at other rpm ranges. A combination of cam overlap,

reversion, and back pressure, or even lack of back pressure, can cause mixture dilution at certain rpm. This will result in loss of power, engine roughness,

or misfiring.

•

Drag pipes - For knucklehead, panhead, shovelhead, and ironhead Harley-Davidson® Sportster® models, 13⁄4" O.D. drag pipes with straight cutoff end

28" to 30" long will work well with almost any camshaft or other performance modification. 2" O.D. drag pipes are not recommended for any application

except very large competition engines.

•

The use of drag pipes is not recommended for Evolution motors in street application.

•

Mufflered exhaust systems - A good, economical street exhaust system consists of stock header pipes with cross-over tube and low restriction mufflers

such as S&S® slip-on mufflers. This system typically produces 10 horsepower more than drag pipes in midrange, where vast majority of normal riding

occurs. Contact S&S for current exhaust recommendations.

•

For any all-out racing application which includes use of air cleaner without element or use of air horn, bowl vent screw (See Picture 36, page 13), should

be removed to insure atmospheric air pressure exists in bowl. If high or low bowl pressure relative to atmospheric pressure develops, engine may run

erratically.

•

Modifying S&S® carburetor - While it is not S&S' intent to discourage purchase of other manufacturers' products, they should be approached with the

understanding that some alter the S&S carburetor's design and function. In such cases, manufacturer of installed item must be contacted for tuning

guidelines, not S&S.

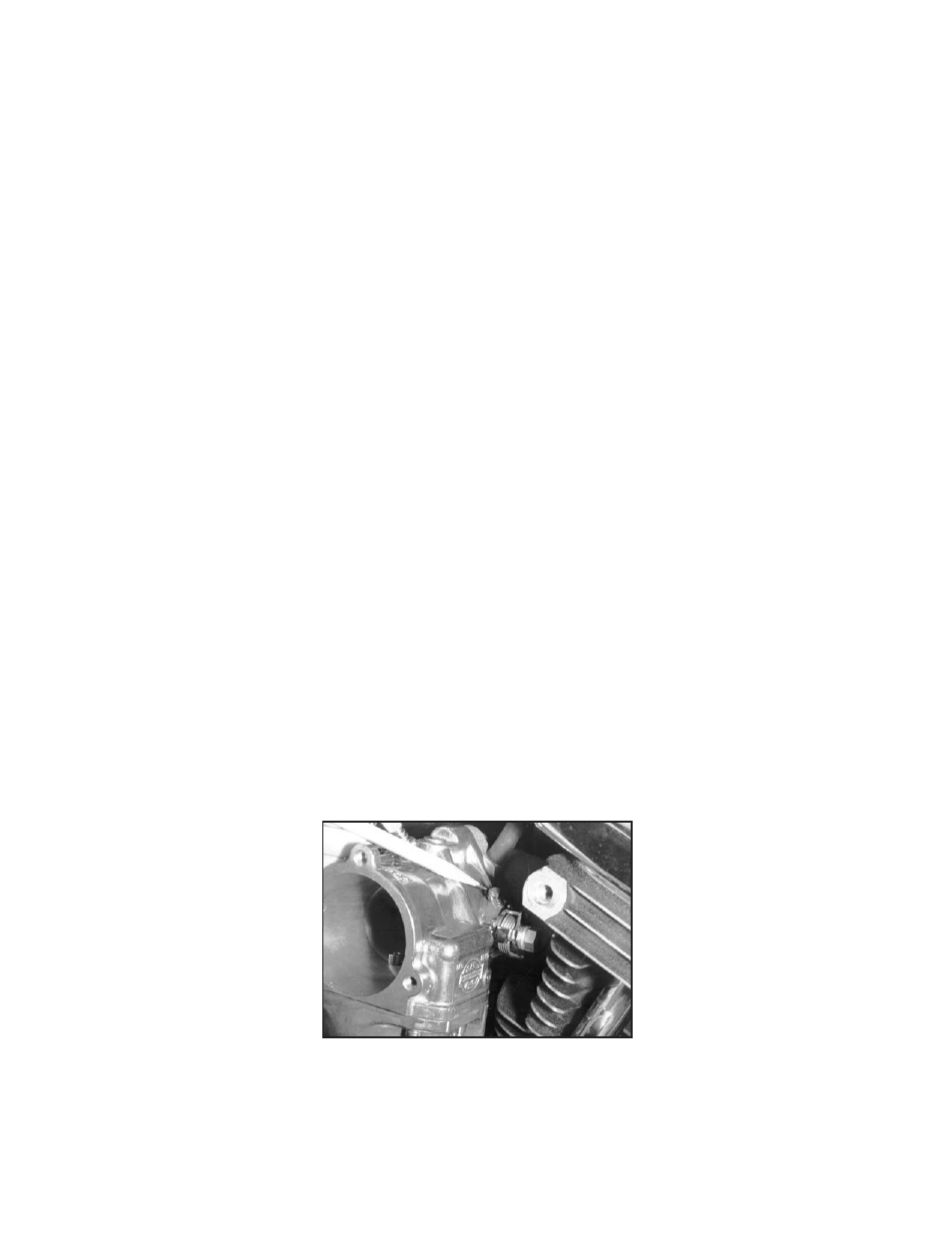

F- Adjusting Accelerator Pump - Function of accelerator pump is to improve throttle response when rapidly opening throttle at low rpm and

to aid cold starts. Pump travel screw regulates volume of fuel delivered by accelerator pump. See Picture 47. During assembly, S&S sets

screw for maximum volume to aid during initial start-up after installation. Turning screw inward or in clockwise decreases delivered pump

volume. Turning screw outward or counterclockwise increases delivered volume.

1- Warm engine to operating temperature.

2- Turn pump travel adjusting screw inward or clockwise until screw contacts pump actuator arm. This limits actuator arm travel and shuts

off pump.

Picture 47