S&S Cycle Super Stock and Special Application Crankcases for 1936-99 Big Twin Engines User Manual

Page 9

9

Installation:

1- Thread plug in hole until it bottoms out against case surface.

2- Tighten plug after ignition timing has been static timed and before starting engine.

H- Assorted screws, washers, etc. See Line Drawing, items 44, 45, 48.

All models

Location and function:

50-0014 1⁄4-20 x 1⁄2“ and 50-0018 1⁄4-20 x 1” hex-head cap screws and 50-7019 1⁄4” lock washers are used to clamp timer assembly down in

1936 to ’69 engines - 1⁄2” screws are for early timers and 1” screw is for later style timers that require separate clamp. 50-0015 1⁄4-20 x 1⁄2”

slotted round head screws and 50-7019 1⁄2” lock washers are used to clamp manual timer advance bracket to bracket boss on 1936-’64

engines. 50-0044 10-24 x 1” socket head cap screws and 50-0045 10-24 x 5⁄16” socket head set screw are used to mount alternator stator and

clamp wires on cases using alternator left case half.

4- Magnetic drain plug

A- Place crankcases in frame to determine if magnetic drain plug 31-2006, located on bottom of cases, will be accessible. If drain plug is

obstructed by skid plate, hole must be drilled in skid plate to provide access.

B- Place large amount of clay or putty on skid plate in general area of drain plug. Drain plug will make impression when cases are placed in

frame over clay.

C- Remove cases and drill hole in skid plate in location indicated by impression in clay. Hole must be large enough to accommodate removal

tool and drain plug.

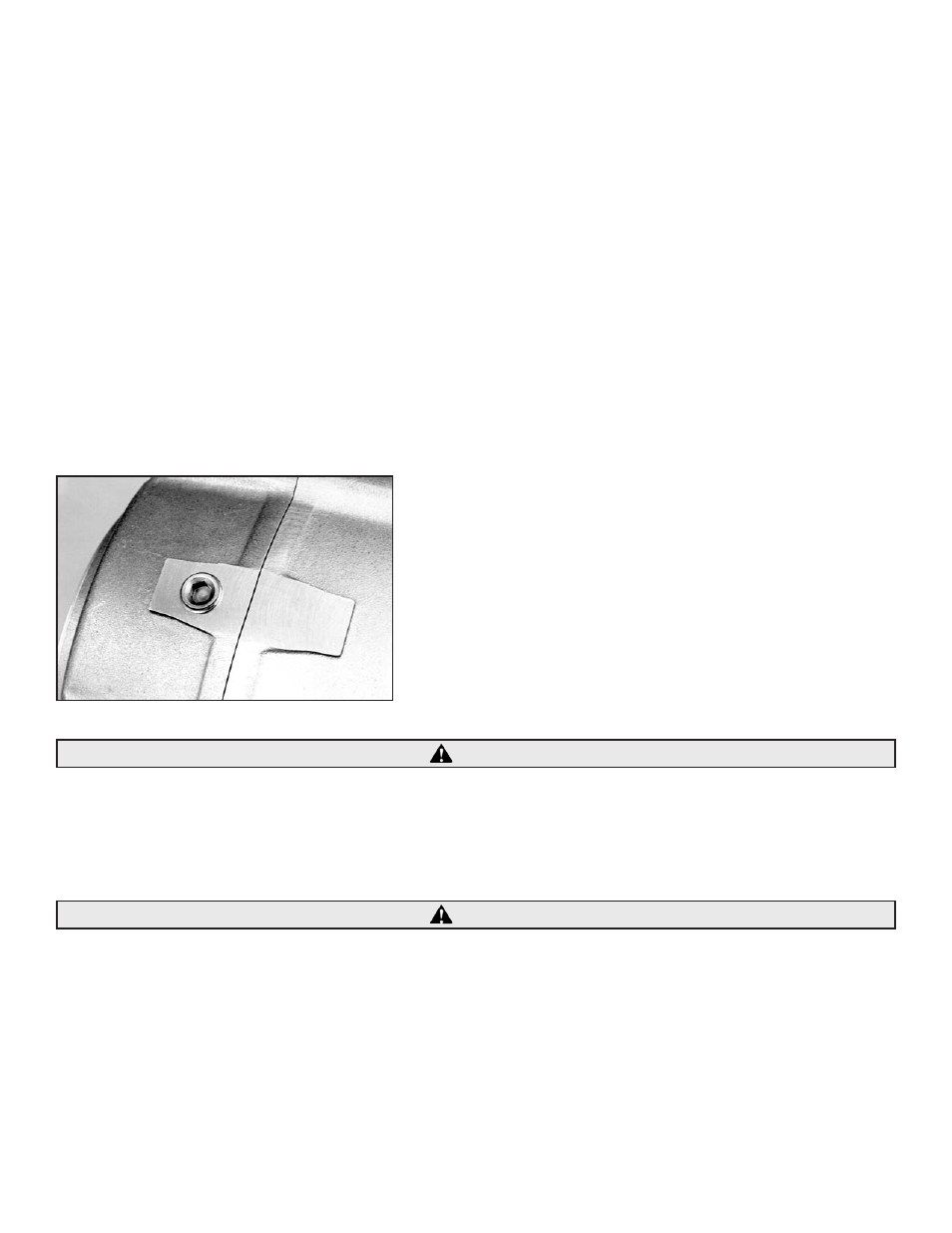

NOTE: When servicing engine, do not overtighten drain plug. Leave at least 1⁄16” of plug above surface of crankcase. See Picture 14.

CAUTION

Picture 14

Overtightening drain plug may cause plug to contact flywheels resulting in damage to flywheels and other engine parts.

NOTE: Check magnetic drain plug for metal particles at 500 mile oil change. Break-in of new engine invariably produces fine metal particles. Small

accumulation of fine material on magnetic drain plug is normal, and simply shows that drain plug is doing its job. Significant amounts of coarse metal

particles or shavings indicate serious engine damage and/or contamination during engine assembly. In this event, engine should be closely inspected

before further operation.

Metal filings, dirt and other contamination in engine oil may cause premature wear and/or irreversible damage to bearings and other

engine components.

CAUTION