S&S Cycle Super Stock and Special Application Crankcases for 1936-99 Big Twin Engines User Manual

Page 10

10

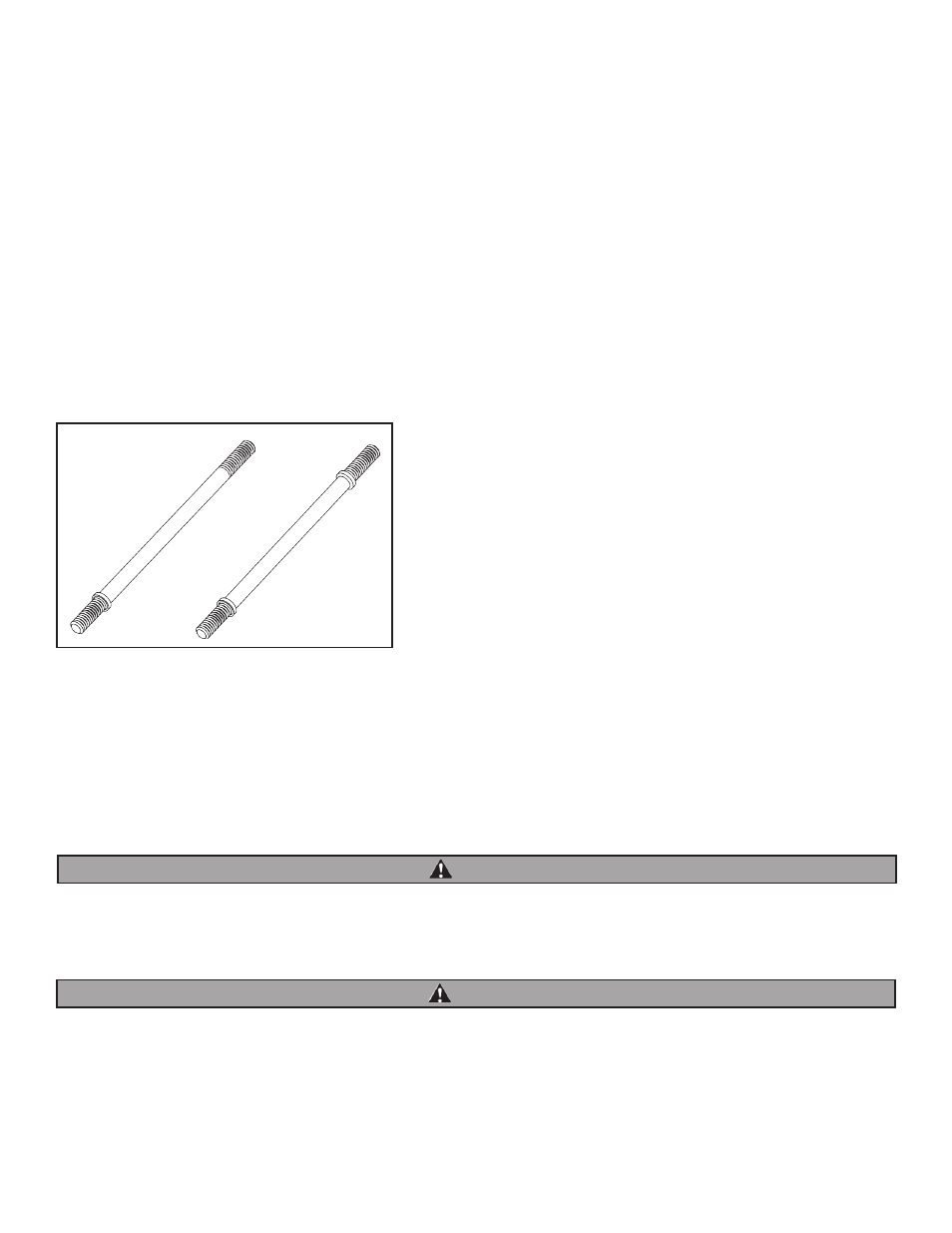

Figure 1 & 2

Figure 1

Figure 2

WARNING

WARNING

5- Cylinder studs

Unless otherwise requested, S&S® installs appropriate cylinder studs in all S&S crankcases prior to shipment.

A- Crankcases made for knucklehead, panhead, or shovelhead cylinders - Cylinder studs are installed to 1.330” for use with S&S Sidewinder® big

bore cylinders as well as stock cylinders. If cylinder base plate is used to increase cylinder height, stud must protrude through gaskets, plate

and flange of cylinder far enough to allow full thread engagement of base nut. Top of stud must be at least flush with top of conventional

base nut.

NOTE : S&S can provide extra long cylinder studs, part 31-2320, for these applications.

B- Crankcases made for 1984-1999 big twin cylinders - Cylinder studs are installed to stock height which is compatible with stock cylinders

or any S&S® Sidewinder® kit for big twin engines. The kits utilize different length head bolt and washer combinations to compensate for

different cylinder heights. These are included in kits with cylinders longer than stock. Builders using kits with stock or shorter than stock

cylinders may shorten stock bolts or purchase bolts of correct length from S&S. If cylinder stud height requirement is different than stock

and extra long bolts will not work, engine builder must install custom studs with at least .750” of stud thread engagement in crankcase. S&S

has produced two styles of cylinder studs for big twin engines. Part 31-2321, replaces H-D® #16937-85C, (See Figure 1) and has a single

collar. When installed correctly collar contacts crankcase cylinder base gasket surface. Part 31-2323 (See Figure 2) has two collars, either of

which can be installed against crankcase cylinder deck.

NOTES

Cylinder studs are easily damaged. Install lengths of 1⁄2” ID. rubber or plastic tubing over each stud to prevent nicks and scratches until top end is

•

assembled. Do not use studs as handle to lift or position crankcases.

Unlike early style stock cylinder studs which rely on interference fit between threads of case and stud to hold them in place, S&S studs have standard

•

thread fit and are secured by combination of thread tension and thread locking compound. Late style stock studs, H-D #16937-85C, have same design.

*All reference to Harley-Davidson® part numbers is for identification purposes only. We in no way are implying that any of S&S® Cycle’s products are

original equipment parts or that they are equivalent to the corresponding Harley-Davidson® part number shown.

Seemingly insignificant damage to studs may cause stress risers which can lead to stud failure and possible damage to engine

•

components.

Insufficient thread engagement between stud and base nut or stud and engine crankcase may result in thread failure and major engine

•

damage.

Thread failure due to insufficient thread engagement could cause violent engine disintegration under power, resulting in loss of control of

motorcycle with serious personal injury.