S&S Cycle Super Stock and Special Application Crankcases for 1936-99 Big Twin Engines User Manual

Page 3

3

CAUTION

The customer must also verify that the serial numbers on the crankcase and attached information tag correspond with those on the certificate of

origin and packing carton. Note that all 4” bore engines require Special Application crankcases, which may be identified by the letters “SA” cast into

the left crankcase below the serial numbers and into the right crankcase immediately ahead of the front lifter guide opening.

Under no circumstance will S&S® be held responsible for expenses related to the modification of any S&S part in the event warranty service is

required. Modified parts will not be accepted for credit or exchange. This will apply regardless of cause or fault: customer, retailer, manufacturer,

or other.

For further information, contact S&S Technical Services at 608-627-8324, FAX 608-627-0766 or e-mail [email protected]

NOTE: Modification includes but is not limited to appearance changes such as painting, powdercoating, plating, and polishing. Proper preparation for

these procedures as well as the processes themselves may require the use of polishing compounds, chemicals or procedures that are potentially harmful

to crankcases.

Passages and internal cavities may become obstructed by residues from materials used to polish, paint, plate or powdercoat surfaces.

•

Additionally, surface finishing processes can damage critical machined surfaces. Any of the above may cause premature wear, damage

or failure of other engine components as well as the crankcases themselves.

Powdercoating - Subjecting heat-treated alloys such as those used in S&S crankcases to excessive heat can drastically alter their

•

strength and their critical properties. The degree of change depends upon the temperatures reached and the duration of exposure.

When powder coating or otherwise processing alloy parts, S&S exposes them to a maximum temperature of 370°F for no longer than

20 minutes. Under no circumstances should parts be heated past 400°F!

Please read these instructions thoroughly before starting work. Proceed with the installation only after they are completely understood.

INSTALLATION INSTRUCTIONS

1- Inspection

A- Inspect crankcases to confirm that they are correct style and machined for correct bore size, flywheel diameter, oil pump pattern, etc. Refer

to tag wired to crankcases.

B- Be sure serial numbers on crankcases match numbers on packing carton and certificate of origin. Contact S&S immediately if numbers do

not match.

C- Trial-fit crankcases in frame as described in Section 9.

NOTES

Valid certificate of origin is required for any transfer or sale of aftermarket crankcases or complete engines built with aftermarket crankcases. Certificate

•

of origin is required to title and license any motorcycle which is to be driven on public streets and highways.

S&S crankcases manufactured before Fall, 1998, require modification for use with 45 amp Harley-Davidson® alternator supplied on ‘97-up fuel injected

•

big twins and available as upgrade kit H-D® #29999-97. See Section 2, Final Preparation, for modification procedure. Performed correctly, 45 amp

alternator modification will not void S&S warranty.

*All reference to Harley-Davidson® part numbers is for identification purposes only. We in no way are implying that any of S&S® Cycle’s products are

original equipment parts or that they are equivalent to the corresponding Harley-Davidson® part number shown.

2- Final Preparation

A- If applicable, modify cases for 45 amp alternator. This step is not required for all models; see preceding note.

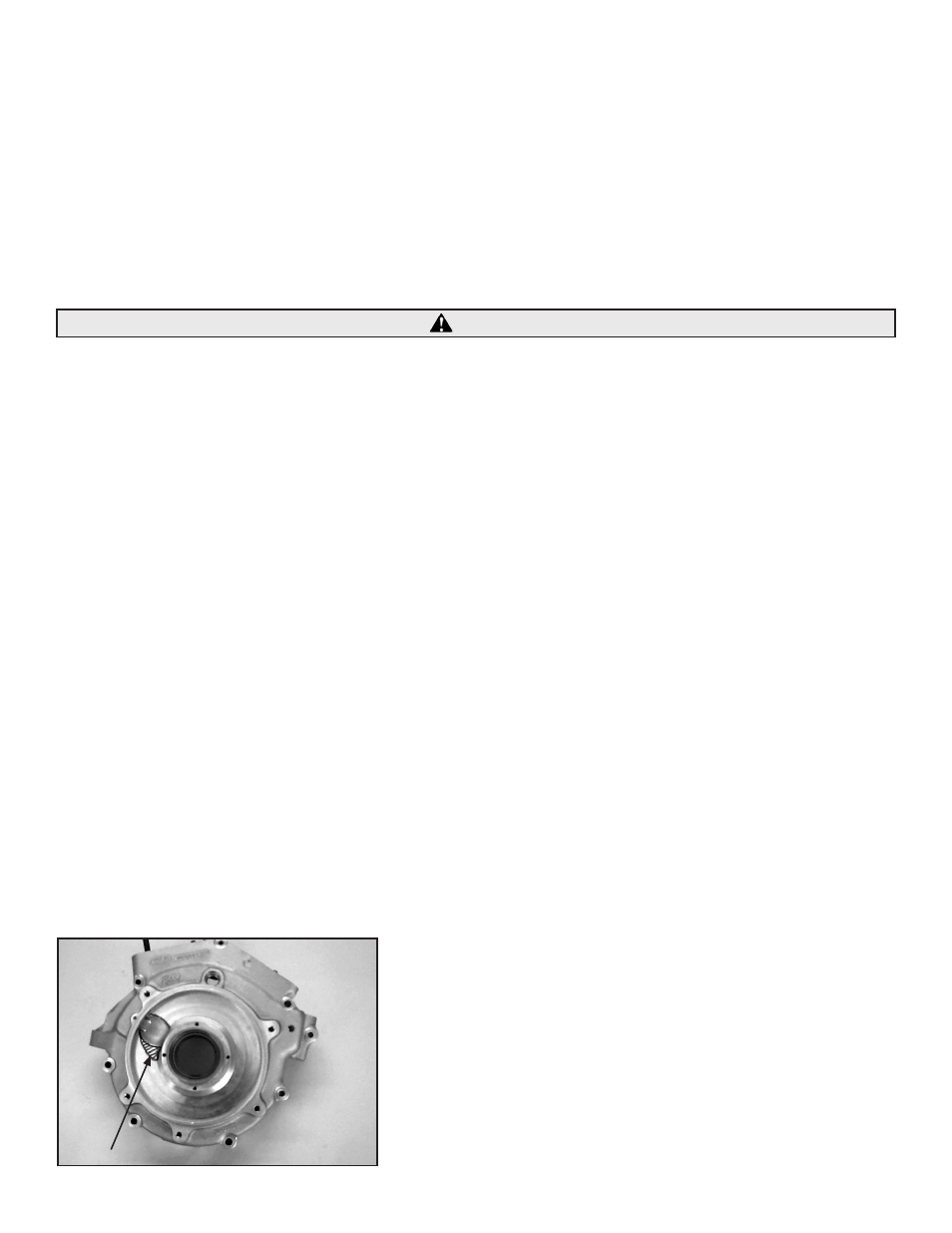

1- Carefully enlarge wiring recess in sprocket side crankcase with mill or hand grinder and remove all metal chips generated during

procedure. See Picture 1.

Picture 1

Remove material in area indicated by shading.